Check of steel connection components (GB)

CBFEM method combines the advantages of the general Finite Element Method (FEM) and standard Component Method (CM). The stresses and internal forces calculated on the accurate CBFEM model are used in checks of all components – Bolts, preloaded bolts, and welds are checked according to GB 50017 – 2017. The plates are checked by finite element analysis. The checks of anchorage have not yet been implemented in the current version.

Code-check of steel plates according to Chinese Standard

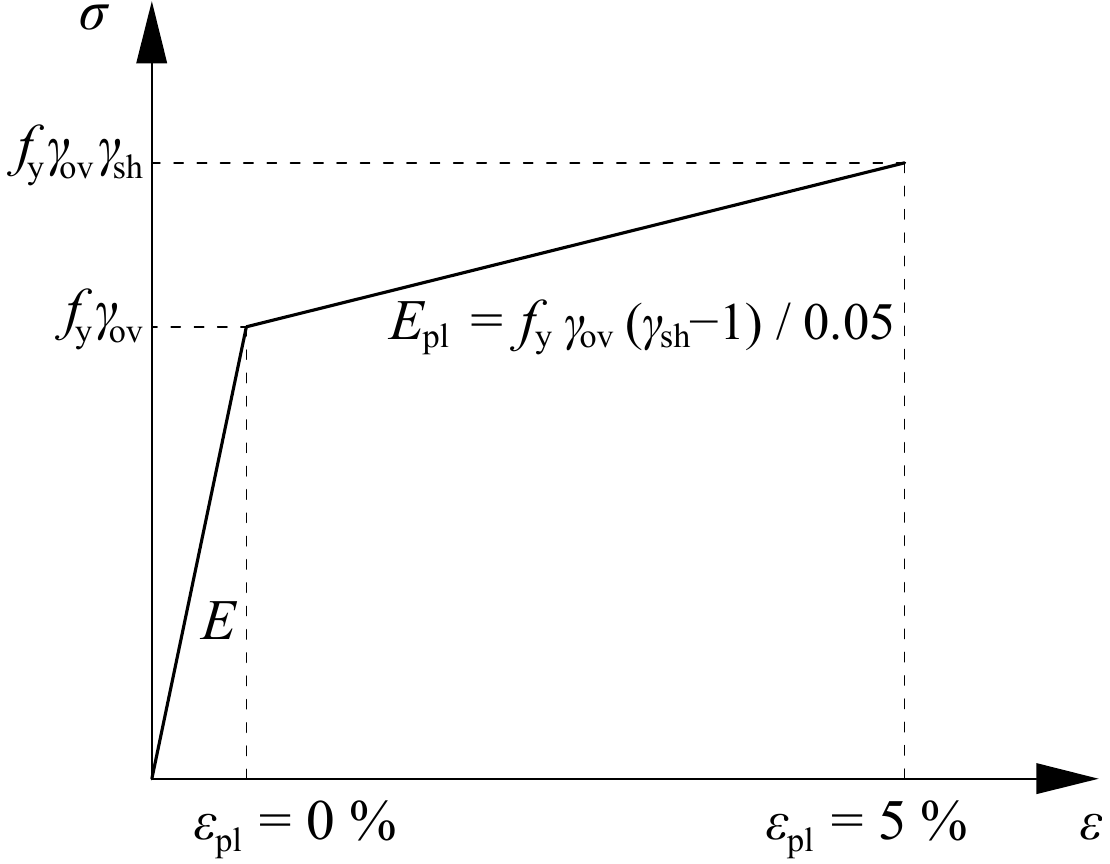

The resulting equivalent stress (HMH, von Mises) and plastic strain are calculated on plates. When the design yield strength, f (GB 50017, Table 4.4.1–4.4.3), on the bilinear material diagram is reached, the check of the equivalent plastic strain is performed. The limit value of 5 % is suggested in Eurocode (EN 1993-1-5 App. C, Par. C8, Note 1). This value can be modified in the Code setup, but verification studies were made for this recommended value.

The plate element is divided into five layers, and elastic/plastic behavior is investigated in each of them. The program shows the worst result of all of them.

Stress may be a little bit higher than the design yield strength. The reason is the slight inclination of the plastic branch of the stress-strain diagram, which is used in the analysis to improve the stability of the calculation.

Code-check of bolts and preloaded bolts according to Chinese standard

Bolts

Bolts are checked according to GB 50017, Cl. 11.4. The tensile and shear force in each bolt is determined by finite element analysis. Prying forces are determined by finite element analysis and taken into account. Each shear plane is checked individually. The plate in the bearing is checked against the sum of shear forces at nearby planes.

Design tensile and shear strengths of a bolt; fub[MPa] – ultimate strength of a bolt; derived from Table 4.4.6

| \(f_{ub}\) [MPa] | \(f_t^b \) | \(f_v^b\) |

| \(f_{ub} \le 400 \) | \(0.425 \cdot f_{ub}\) | \(0.35 \cdot f_{ub}\) |

| \(400<f_{ub}<830\) | \(0.42 \cdot f_{ub}\) | \(0.38 \cdot f_{ub}\) |

| \(830 \le f_{ub}\) | \(40/83 \cdot f_{ub}\) | \(32/83 \cdot f_{ub}\) |

Bolt in tension

A bolt subject to a tensile force is designed according to Cl. 11.4.1.2 and shall satisfy:

\[ N_t \le N_t^b = A_s \cdot f_t^b \]

where:

- Nt – tensile force in a bolt

- Ntb – design tension capacity

- \( A_s = \frac{\pi d_e^2}{4} \) – tensile stress area of a bolt

- de – effective diameter of a bolt at threaded section

- ftb – design tensile strength of a bolt

Bolts in shear

A bolt subject to a shear force is designed according to Cl. 11.4.1.1 and shall satisfy:

\[ N_v \le N_v^b = A_g \cdot f_v^b \]

where:

- Nv – shear force in a bolt in investigated plane

- \( A_g = \frac{\pi d^2}{4} \) – gross cross-section area of a bolt

- d – nominal diameter of a bolt

- fvb – design shear strength of a bolt

Each shear plane is checked individually, i.e. number of shear planes nv = 1.

Bolts in combined tension and shear

A bolt loaded in shear and tensile forces at the same time is designed according to Cl. 11.4.1.3 and shall satisfy:

\[ \sqrt{\left ( \frac{N_v}{N_v^b} \right ) ^2 + \left ( \frac{N_t}{N_t^b} \right ) ^2} \le 1.0 \]

where:

- Nv – shear force in a bolt in investigated plane

- Nt – tensile force in a bolt

- Nvb – design shear resistance of a bolt

- Ntb – design tensile resistance of a bolt

Bolts in bearing

A plate subject to a bearing force due to a bolt in shear is designed according to Cl. 11.4.1.1 and shall satisfy:

\[ N_v \le N_c^b = d\cdot t \cdot f_c^b \]

where:

- Nv – shear force in acting on a plate; vector sum of shear forces in nearby planes

- d – nominal bolt diameter

- t – plate thickness

- fcb – design bearing strength of a plate

Design bearing strength of a plate; fu – ultimate strength of a plate; derived from Table 4.4.6

Preloaded bolts

High strength bolt in friction type joint is designed according to Cl. 11.4.2.

Preloaded bolts in tension

The tensile resistance of a preloaded bolt is determined as:

\[ N_t \le N_t^b = 0.8 \cdot P \]

where:

- Nt – tensile force in a bolt

- Ntb – design tension capacity

- P – pretension of a high strength bolt – Table 11.4.2-2

Table 11.4.2-2 – pretension of a high strength bolt P [kN]

| Bolt grade | M16 | M20 | M22 | M24 | M27 | M30 |

| 8.8 | 80 | 125 | 150 | 175 | 230 | 280 |

| 10.9 | 100 | 155 | 190 | 225 | 290 | 355 |

A preloaded bolt which is not in Table 11.4.2-2 subject to a tensile force is designed according to Cl. 11.4.1.2 and shall satisfy:

\[ N_t \le N_t^b = A_s \cdot f_t^b \]

where:

- Nt – tensile force in a bolt

- Ntb – design tension capacity

- \( A_s = \frac{\pi d_e^2}{4} \) – tensile stress area of a bolt

- de – effective diameter of a bolt at threaded section

- ftb – design tensile strength of a bolt

Preloaded bolts in shear

The design resistance of a preloaded bolt in shear is determined according to Cl. 11.4.2.1:

\[ N_v \le N_v^b = 0.9 k \mu P \]

where:

- Nv – shear force in investigated plane

- Nvb – design shear resistance of a bolt

- k – factor for bolt holes; k = 1 for normal holes, k = 0.85 for oversized holes, k = 0.6 for slotted holes

- μ – slip coefficient at friction interface taken from Table 11.4.2-1; editable in Code setup

- P = Ntb / 0.8 – pretension of a high strength bolt for bolts which are not in Table 11.4.2-2

Each shear plane is checked individually, i.e. number of shear planes nf = 1.

Preloaded bolts in combined tension and shear

A bolt loaded in shear and tensile forces at the same time is designed according to Cl. 11.4.2.3 and shall satisfy:

\[ \frac{N_v}{N_v^b} + \frac{N_t}{N_t^b} \le 1.0 \]

where:

- Nv – shear force in investigated plane

- Nt – tensile force in a bolt

- Nvb – design shear resistance of a bolt

- Ntb – design tensile resistance of a bolt

Code-check of welds according to Chinese standard

Fillet welds are checked according to GB 50017 - Chapter 11. The strength of butt welds is assumed the same as the base metal and is not checked.

Butt welds

Full penetration butt welds are expected, and their resistance is considered equal to that of the parent metal – Cl. 11.2.1.

Fillet welds

Design resistance of fillet welds is checked according to Cl. 11.2.2.2:

\[ \sigma_w = \sqrt{ \left ( \frac{\sigma_f}{\beta_f} \right ) ^2 + \tau_f^2} \le f_f^w \]

where:

- σf – stress on the effective area of the weld perpendicular to the weld length

- βf – enlargement coefficient for design value of fillet weld strength; βf = 1.22 for static loading and angle between fusion faces α = 90°; otherwise βf = 1.0

- τf – shear stress on the effective area of the weld parallel to the weld length

- ffw – design fillet weld strength

Design fillet weld strength ffw for welding electrodes; derived from Table 4.4.5

| Electrode | \(f_f^w\) [MPa] |

| E43 | 160 |

| E50 | 200 |

| E55 | 220 |

| E60 | 240 |

Default electrodes are E43 for the weakest connected plate with fu < 470 MPa, E50 for 470 MPa ≤ fu < 520 MPa, and E55 for 520 MPa ≤ fu.

The weld diagrams show stress according to the following formula:

\[ \sigma = \sqrt{ \frac{1}{\beta_f^2}(\sigma_{\perp}^2 + \tau_{\perp}^2) + \tau_{\parallel}^2 } \]

Detailing of bolts and welds according to Chinese standard

Bolts

The minimum allowable distance of bolts is checked according to Table 11.5.2.

Minimum allowable distance of bolts; d0 – bolt hole diameter

| Minimum allowable distance | |

| Bolt pitch | \( 3 \cdot d_0 \) |

| End distance parallel to load | \( 2 \cdot d_0 \) |

| Edge distance perpendicular to load (bearing bolt type) | \( 1.2 \cdot d_0 \) |

| Edge distance perpendicular to load (preloded bolt type) | \( 1.5 \cdot d_0 \) |

Welds

The minimal weld size hf is checked according to Table 11.3.5. The weld size is determined from weld throat thickness: \( h_f = \sqrt{2} \cdot h_e \).

Minimal weld size hf

| Thickness of plate [mm] | Minimum weld size [mm] |

| \( t \le 6 \) | 3 |

| \( 6 < t \le 12 \) | 5 |

| \( 12 < t \le 20 \) | 6 |

| \( 20<t \) | 8 |

Code-check of concrete block according to Chinese standard

The concrete below the base plate is simulated by Winkler subsoil with uniform stiffness, which provides the contact stresses. The average stress at the bearing area used for compressive check.

Concrete in bearing

User can choose between local bearing capacity check of reinforced concrete pad (GB 50010, Equation 6.6.1-1) and plain concrete pad (GB 50010, Equation D.5.1-1).

Reinforced concrete pad

\[ F_l \le F_c = 1.35 \beta_c \beta_l f_c A_{ln} \]

Plain concrete pad

\[ F_l \le F_c = \omega \beta_l f_{cc} A_l \]

where:

- Fl – compressive force

- Fc – compressive resistance

- βc – strength influential coefficient of concrete; βc = 1 for concrete grade up to C50, βc = 0.8 for concrete grade C80; linear interpolation is used for concrete grade between C50 and C80

- \( \beta_l = \sqrt{\frac{A_b}{A_l}} \) – concentration factor

- Ab – concrete supporting surface which is concentric to Al

- Al – base plate area in contact with concrete surface

- Aln – area Al with subtracted holes in base plate for anchors

- fc – design compressive strength of concrete; GB50010, Table 4.1.4-1

- fcc = 0.85 fc – design compressive strength of plain concrete; GB50010, Table 4.1.4-1

- ω – compression load distribution factor; ω = 0.75 for uneven load distribution, ω = 1.0 for even load distribution

Transfer of shear

The shear action at the base plate is assumed to be transferred from the column to the concrete foundation by:

- Friction between base plate and concrete / grout

- Shear lug

- Anchor bolts

Anchors

The tensile forces in anchors include prying forces and are determined by finite element analysis.

Anchors are not checked in the software.

Joint classification according to Chinese standard

Joints are classified according to joint stiffness to:

- Rigid – joints with insignificant change of original angles between members,

- Semirigid – joints which are assumed to have the capacity to furnish a dependable and known degree of flexural restraint,

- Pinned – joints which do not develop bending moments.

There is no clear boundary between joint classes in GB 50017 and therefore, joints are classified according to the EN 1993-1-8 – Cl. 5.2.2.

- Rigid – \( \frac{S_{j,ini} L_b}{E I_b} \ge k_b \)

- Semirigid – \( 0.5 < \frac{S_{j,ini} L_b}{E I_b} < k_b \)

- Pinned – \( \frac{S_{j,ini} L_b}{E I_b} \le 0.5 \)

where:

- Sj,ini – initial stiffness of the joint; the joint stiffness is assumed linear up to the 2/3 of Mj,Rd

- Lb – theoretical length of the analyzed member; set in member properties

- E – Young's modulus of elasticity

- Ib – moment of inertia of the analyzed member

- kb = 8 for frames where the bracing system reduces the horizontal displacement by at least 80 %; kb = 25 for other frames, provided that in every storey Kb/Kc ≥ 0.1. The value of kb = 25 is used unless the user sets "braced system" in Code setup.

- Mj,Rd – joint design moment resistance

- Kb = Ib / Lb

- Kc = Ic / Lc

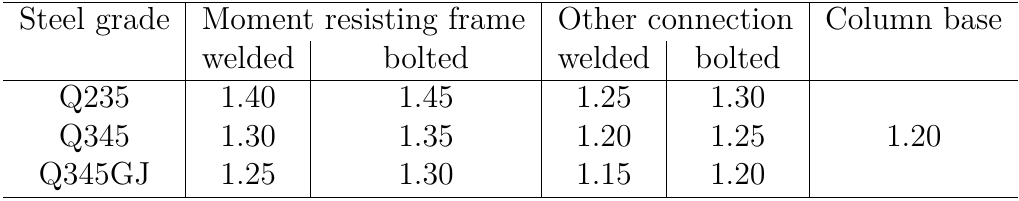

Capacity design according to Chinese standard

Capacity design is a part of seismic check and ensures that the joint has sufficient deformation capacity.

The connections must be able to safely transfer the force necessary to create a plastic hinge in a dissipative item. The dissipative item is selected by user alongside with the connection coefficient ηj taken from GB 50017-2017, Table 17.2.9. The connection coefficient ηj is divided between the overstrength factor γov and strain-hardening factor γsh; ηj = γovγsh. Strain-hardening factor γsh is defined by the user, and it is recommended as γsh = 1.1 for beam in moment resisting frame and γsh = 1.0 for other dissipative items. It is recommended to choose the safer ηj; e.g. ηj = 1.35 for the dissipative beam from steel grade Q345 in the moment resisting frame for the checks of both welds and bolts.

Connection coefficient ηj according to Table 17.2.9

Material diagram of the dissipative item