Welded Metal Building Connections

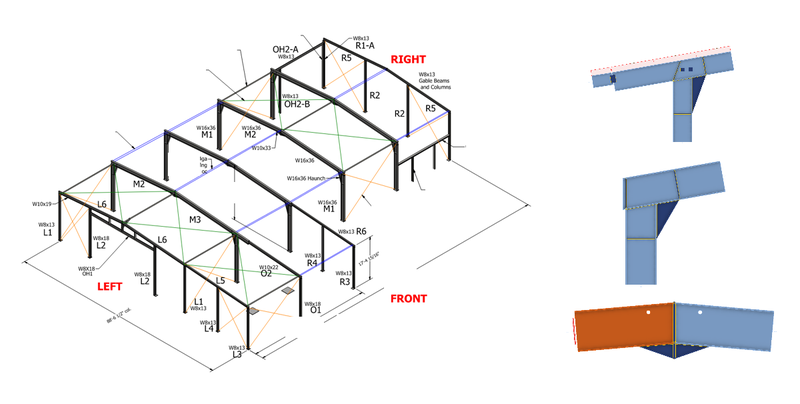

Flint Engineering worked on a metal building project in a bit of a hybrid approach. They were in charge of the foundations and the design of the main moment frames only. The fabricator didn’t want them to touch any of the light gauge material. Usually, the structural engineer oversees the whole building. In this case, Flint Engineering needed to make sure the structure was stable and sound and coordinate with the client on the other parts of the structure.

Another unique part of this project is their client, the fabricator, wanted all welded connections, so there were no bolts on any of the frames.

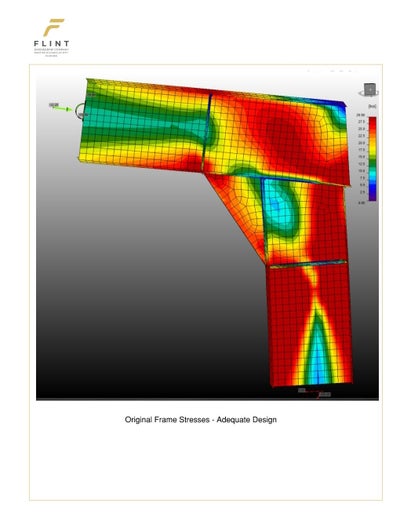

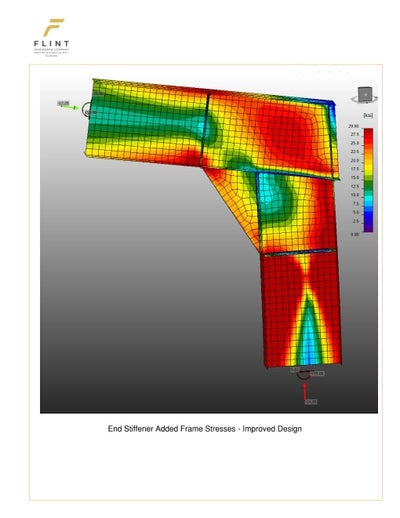

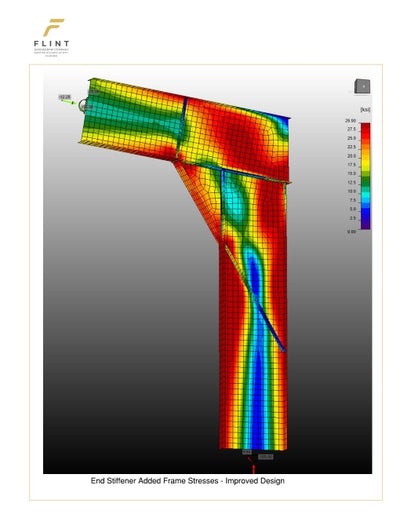

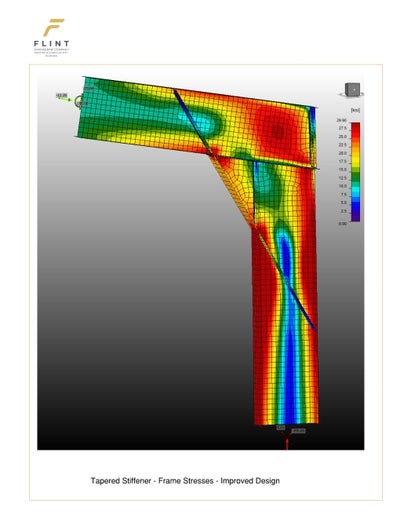

Flint incorporated IDEA StatiCa in their workflow, looking for efficiency in the design by using all the modeling capabilities for welds and the possibility of adding stiffeners in any part of the connection.

The fabricator also wanted to reuse the material they had in their shop for the haunches. For instance, in the following moment splice plate connection, a W10x33 was available to be used as a haunch.

IDEA StatiCa Connection allowed them to use the cross-section properties for the modeling of the haunch, specifically modeling a stiffening member and selecting the available material from the shop.

United States

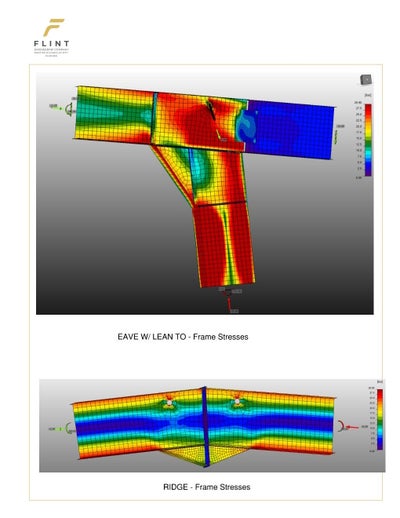

The second example discussed is at the end of the moment frame that has a change in cross-section height. The moment beam is extended out past the working point, and at the same time, rod X braces are attached to the beam's web, adding out of plane tension forces.

IDEA StatiCa allowed Flint Engineering to model all the elements in the joint and represent the X braces' connection to the web, which in real life was connected with a Hillside washer. The solution to the connection is shown in the following portion of the webinar.

Webinar recording

Watch the Flint Engineering Company project webinar recording to find out more about this project.