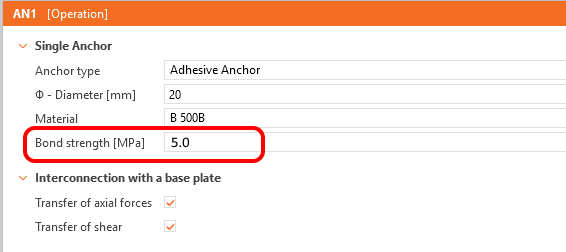

Bond strength for anchors in Detail 3D

Bond strength property of a Single anchor in Detail 3D is the design value of bond resistance of Adhesive (post-installed) anchor. It is a crucial parameter for anchoring design in Detail 3D.

In terms of EN 1992-4, we can define design bond resistence as τRd = τRk /γMp

γMp is partial safety factor defined by table 4.1 in EN 1992-4

γMp = γMc = γc ⋅ γinst

γc = 1.5

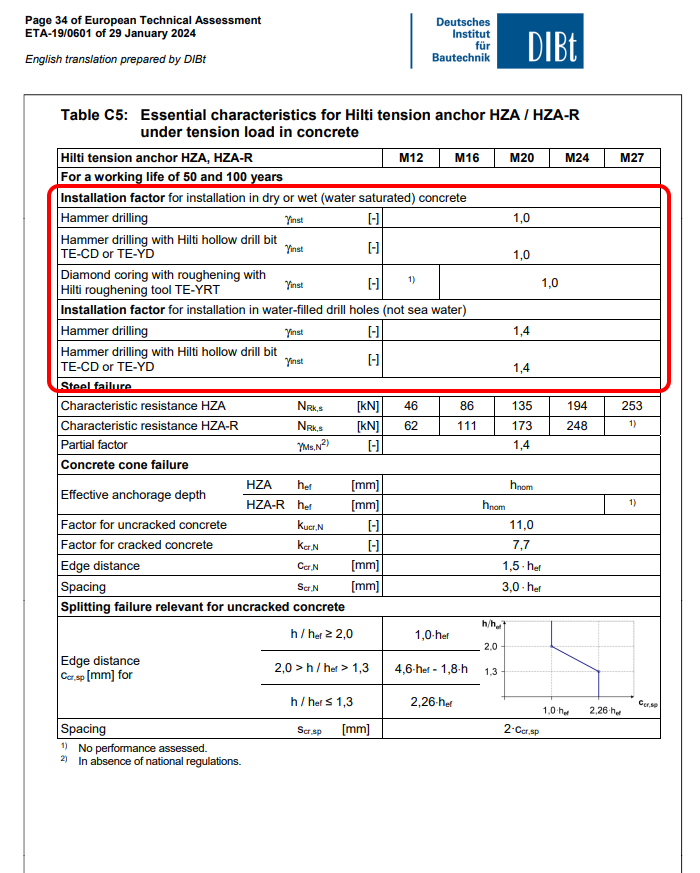

γinst - factor accounting for the sensitivity to installation of post-installed fasteners. Can be found in relevant European Technical Product Specification for the specific product.

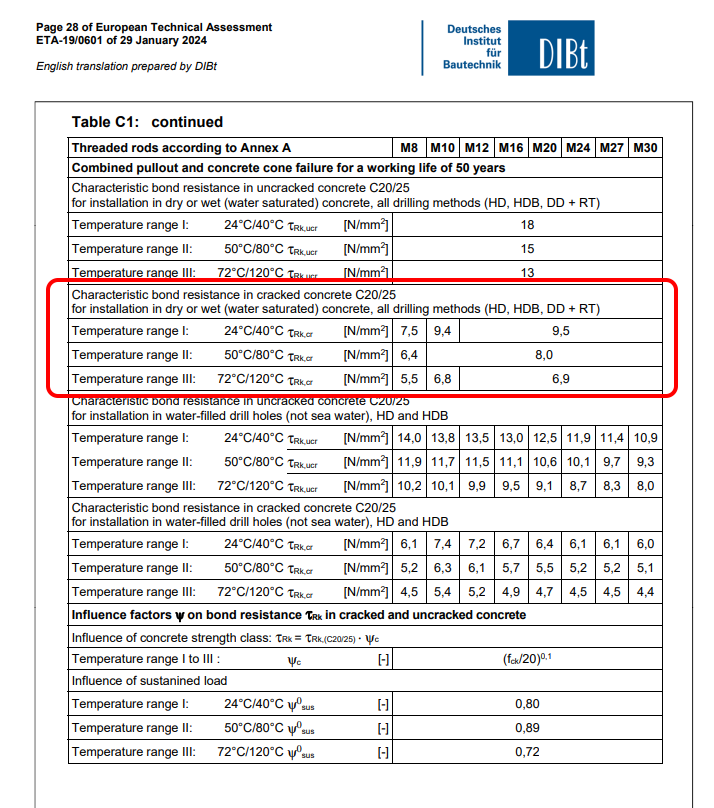

τRk - is characteristic bond resistance of a post-installed bonded fastener. Depending on concrete strength class, and state of the concrete – cracked vs. uncracked. It can be found in certificate for injection mortar, for example ETA – European Technical Assesment.

Example

Lets have post-installed bonded anchor made from M12 threaded bar and mortar Hilti HIT-HY 200-A V3. The hole is hammer-drilled. The anchor is installed in dry conditions into cracked C20/25 concrete. Design life is 50 years.

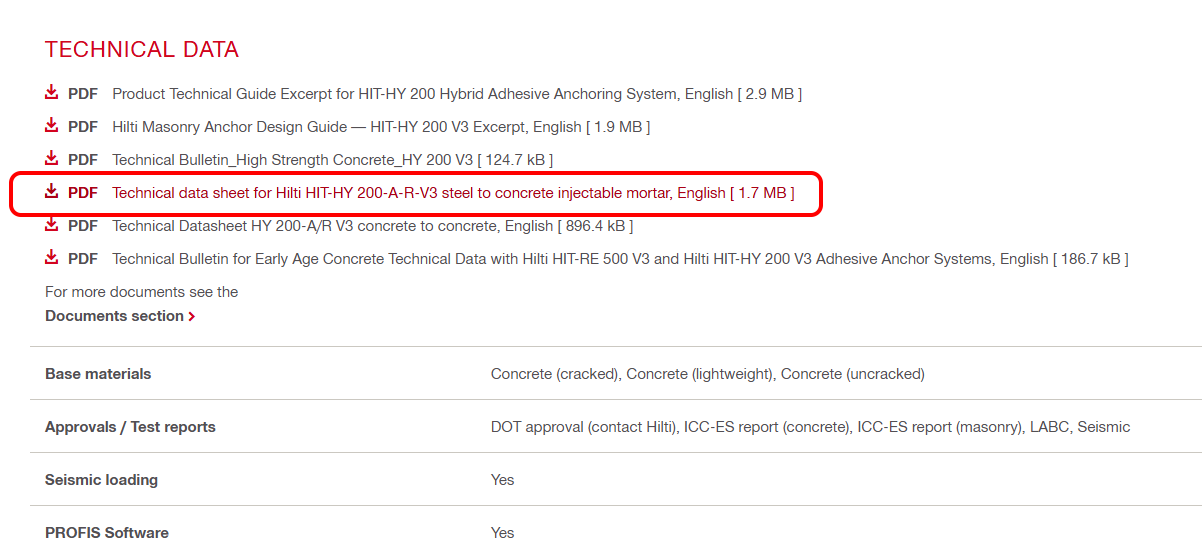

At first we need to go to HIT-HY 200-A product web page here. We are looking for ETA document. Go to Technical data section of the page and open PDF document Technical data sheet for Hilti HIT-HY 200-A-R-V3 steel to concrete injectable mortar, English.

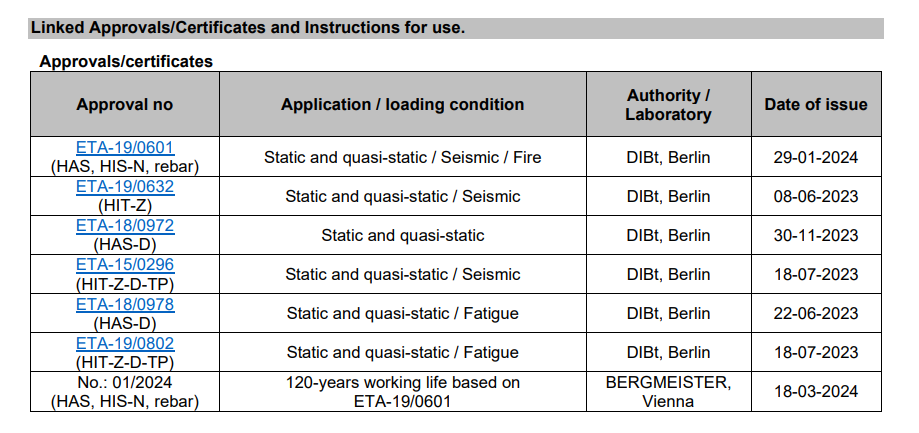

On page 3 of the document, you can find links to relevant ETA documents.

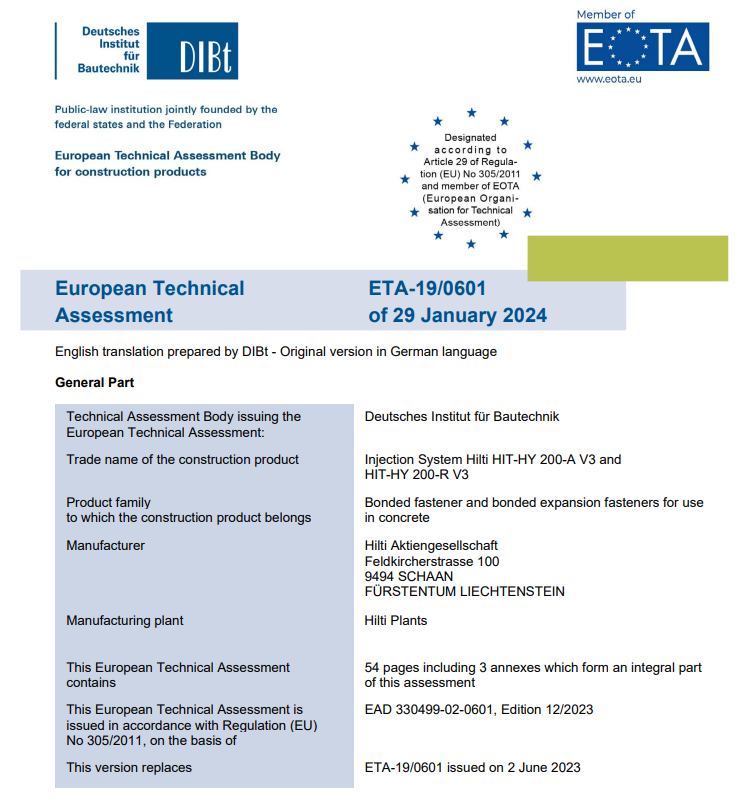

Open ETA-19/0601 linked in the first row of the table, which is relevant for us.

In table C1 of this document, you can find data for τRk - characteristic bond resistance. Conservatively for temperature range II, in our case τRk = 8.0 MPa.

In table C1 of the document, you can also find relevant γinst values. In our case γinst = 1.0.

The final value of design bond strength is τRd = 8.0 /(1.5x1.0) = 5.3 MPa.