Prequalified Steel Connections (AISC) - Summary, Conclusion, and Recommendations

The series of verification examples was prepared in a joint project between Ohio State University and IDEA StatiCa. The authors are listed below:

- Baris Kasapoglu, Ph.D. student

- Ali Nassiri, Ph.D.

- Halil Sezen, Ph.D.

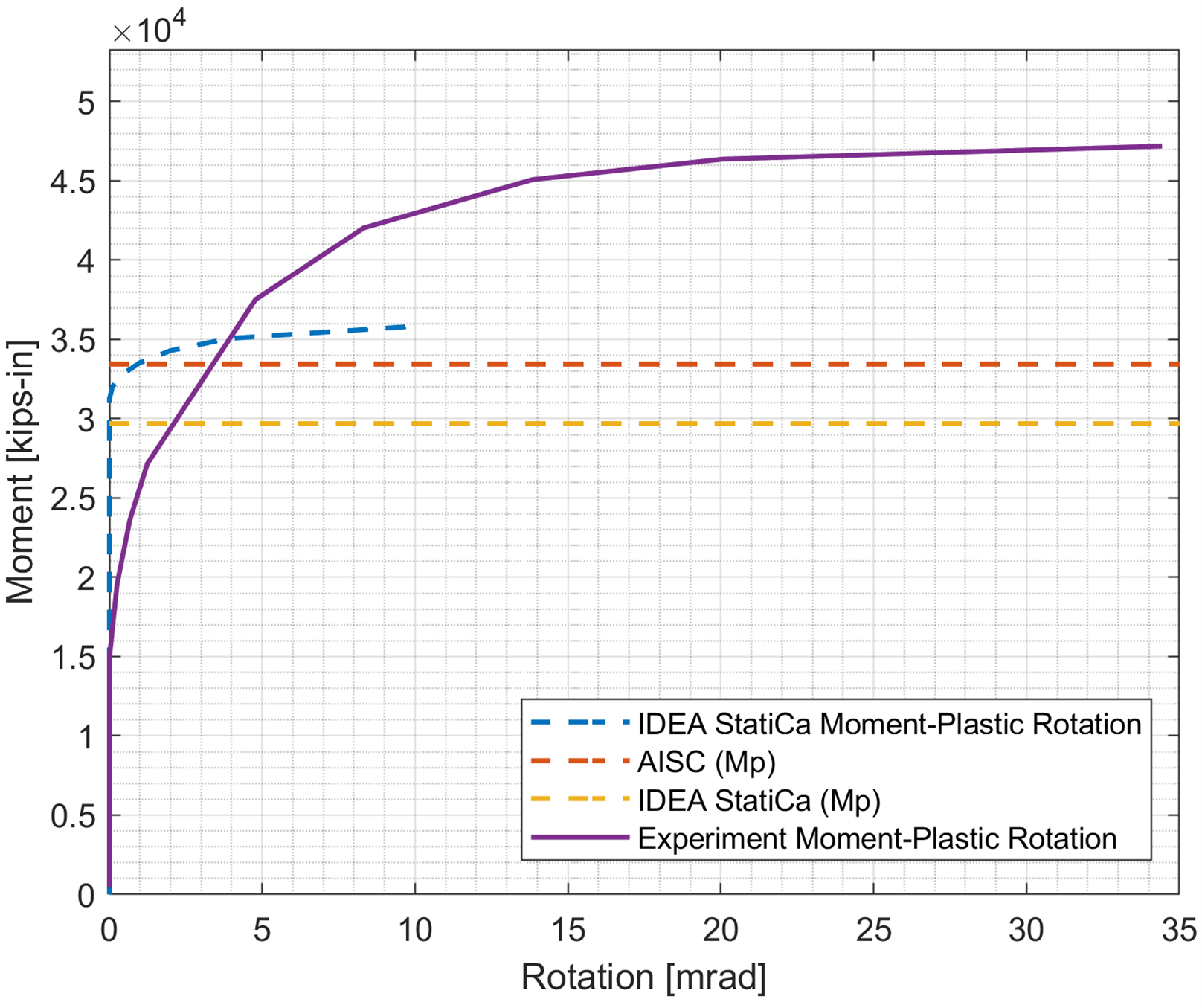

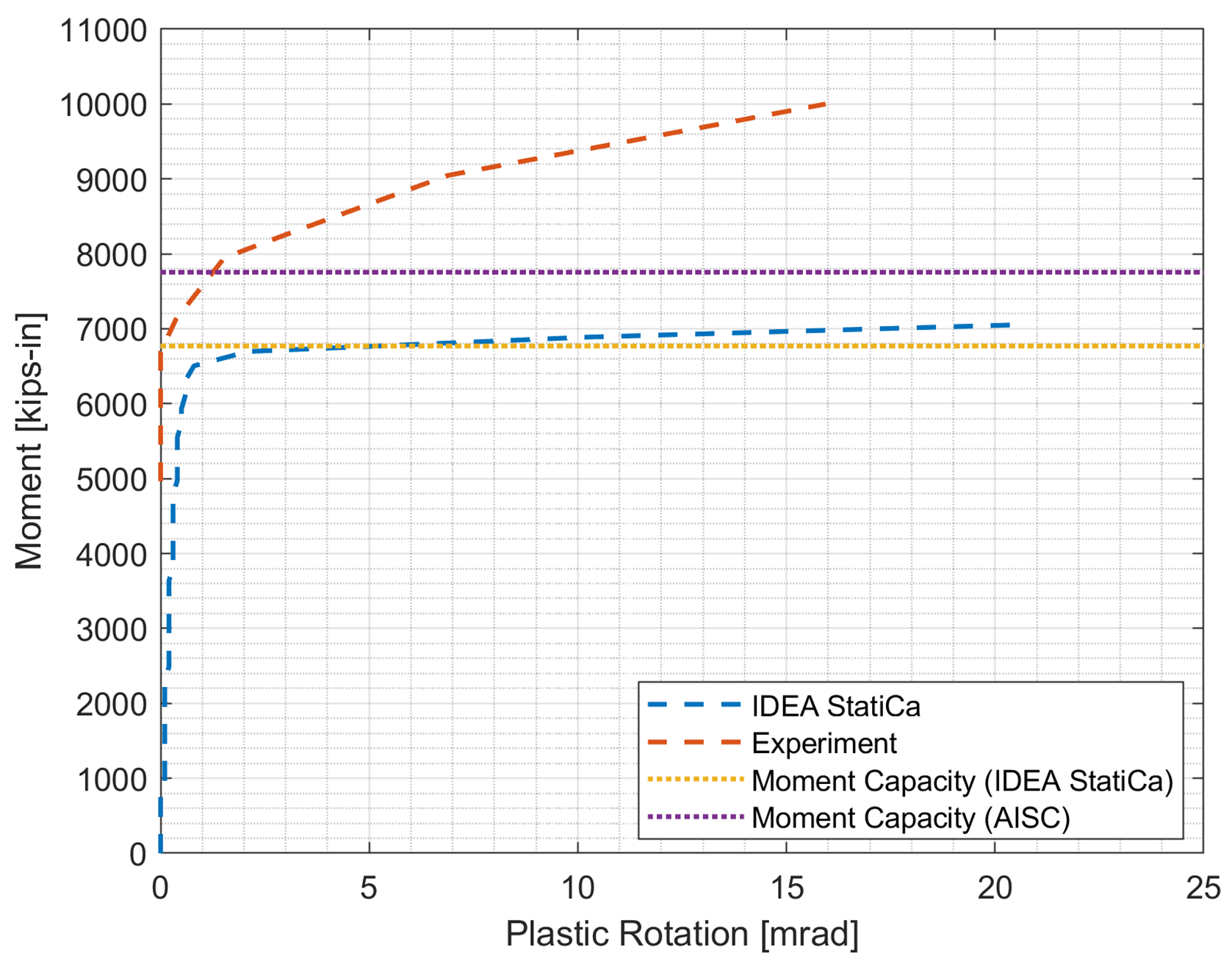

Reduced beam section (RBS) moment connection

One tested RBS moment connection was chosen from an experimental study (Uang et al., 2000) and five additional variations were created. The moment strength capacities of six specimens with failure modes were estimated following the AISC procedure and using IDEA StatiCa. Differences between the calculated capacities (1- moment capacity by IDEA StatiCa/moment capacity calculated by AISC procedure) vary from -3% to +7%, while the average difference is approximately 4% (Table 6.1). Also, the moment rotation relationship calculated by IDEA StatiCa using stiffness analysis was compared with the one provided in the test report (Figure 6.1). It can be seen that IDEA StatiCa is capable of identifying the failure mode, calculating the moment strength capacity, and the moment rotation curve of RBS moment connections.

Table 6.1: Flexural moment strength of RBS moment connections calculated by IDEA StatiCa and AISC procedure (with respect to column face)

| Specimen No | AISC Flexural moment capacity (kips-in.) | IDEA StatiCa Flexural moment capacity (kips-in.) | IDEA/AISC |

| Baseline | 13,422 | 13,874 | 1.03 |

| Var-1 | 11,162 | 10,800 | 0.97 |

| Var-2 | 6,847 | 7,345 | 1.07 |

| Var-3 | 11,983 | 12,157 | 1.01 |

| Var-4 | 6,844 | 7,338 | 1.07 |

| Var-5 | 6,842 | 7,337 | 1.07 |

Figure 6.1: Moment (with respect to column centerline) plastic rotation comparison of RBS moment connection (baseline model)

Read the full verification example article on the Reduced Beam Section

End plate moment (EPM) connection

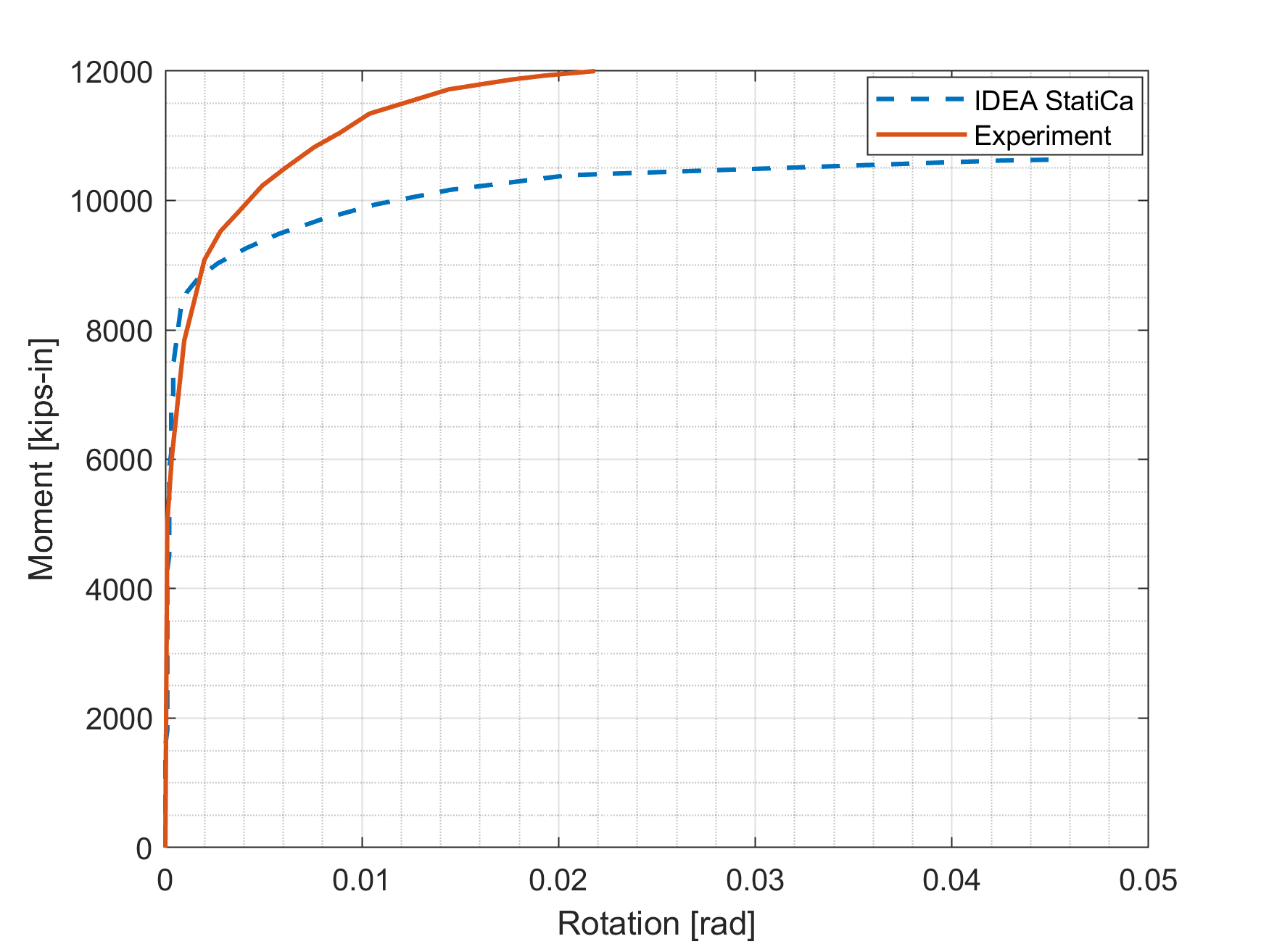

Six tested EPM connections were assessed following the AISC design procedure and using IDEA StatiCa. Their moment capacities and failure modes were calculated and compared with the observations from the experiment (Sumner et al., 2000). Differences between the results vary from -7% to +11% while the average difference is approximately 2% (Table 6.2). It should be noted that the end plate yielding is controlling limit state for variation 3 where 11% difference is calculated while the insufficient weld strength between end plate and beam web is the failure mode observed from IDEA StatiCa analysis. When the weld reaches its strength limit, 1.9% of plastic strain is calculated in the end plate which is less than 5% of plastic strain limit for plates. From this example, it can be interpreted that the procedure outlined in AISC 358 for end plate yielding limit state provides a more conservative result than IDEA StatiCa. For the baseline model, the moment rotation curve obtained using IDEA StatiCa was compared with the experimentally measured one. IDEA StatiCa shows its capability in estimating the bolt rupture capacity including the effects of prying on strength capacity of bolts and the contribution of end plate stiffener on the flexural strength of EPM specimens. The difference between slopes after yielding and the gap between the reached peak moment values can be attributed to the stiffness degradation that the test specimen experienced and the bilinear material model used by IDEA StatiCa, respectively.

Figure 6.2: Moment (with respect to column centerline) plastic rotation comparison of EPM connection (baseline model)

Table 6.2: Flexural moment strength of EPM connections calculated by IDEA StatiCa and AISC procedure (with respect to column face)

| Specimen No | AISC Flexural moment capacity (kips-in.) | IDEA StatiCa Flexural moment capacity (kips-in.) | IDEA/AISC |

| Baseline | 10,216 | 9,969 | 0.98 |

| Var-1 | 8,669 | 8,856 | 1.02 |

| Var-2 | 34,323 | 36,298 | 1.06 |

| Var-3 | 17,327 | 19,310 | 1.11 |

| Var-4 | 18,338 | 19,275 | 1.05 |

| Var-5 | 30,890 | 28,595 | 0.93 |

Read the full verification example article on the End plate moment (EPM) connection

Welded unreinforced flange-welded web (WUF-W) moment connection

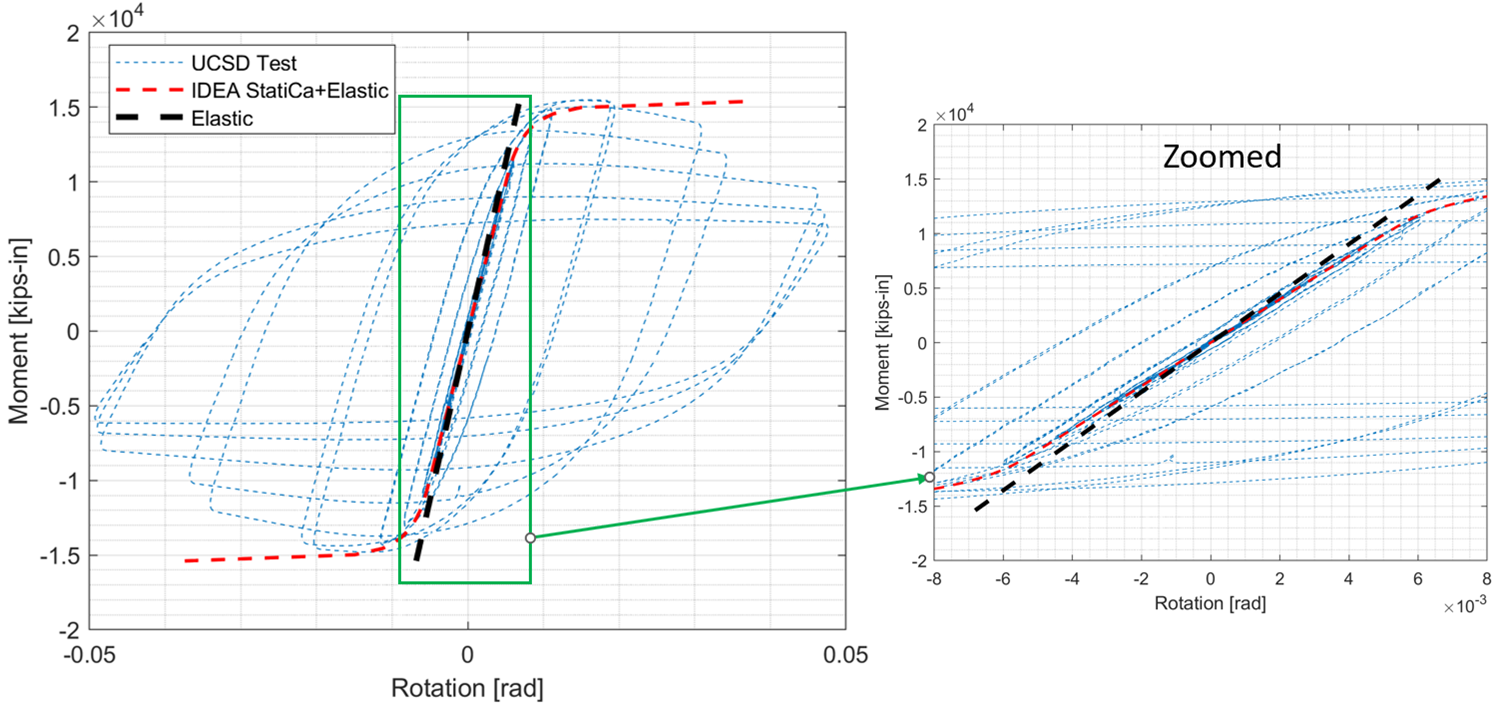

The moment capacities and failure modes of six tested WUF-W specimens were calculated using IDEA StatiCa and following the AISC design procedure, and the observations were compared with the results of the tests performed by Ricles et al. (2000). The failure modes obtained from three sources are similar in all connections while the moment capacities calculated using IDEA StatiCa are approximately 8% larger than those obtained from AISC design procedure except the baseline model (Table 6.3). The reason that IDEA StatiCa calculates larger moment capacities than AISC procedure for variations can be associated with the assumption of plastic hinge location. It is recommended to be taken at column face by AISC 358 for WUF-W moment connections which leads to a lesser additional moment due to the shear force at the plastic hinge location compared to the case that it occurs a distance away from the column face. For the baseline model, IDEA StatiCa analysis shows that the specimen reaches its capacity when the weld between column face and shear tab fails. Similarly, hand calculations performed following AISC design procedure indicate that the weld does not satisfy the required strength limit. However, there is no procedure outlined by AISC to calculate moment capacity of these type of connections controlled by the weld between the column and beam or shear tab. It should be noted that the calculated moment capacity following AISC procedure is based on plastic moment strength of the beam though this connection is not permitted to be designed by AISC since the strength requirement for the weld is not satisfied. Overall, the average difference between the moment capacities calculated by IDEA StatiCa and AISC procedure is approximately 5%. In addition, moment rotation analysis was performed using IDEA StatiCa and ABAQUS for the baseline model and the results were compared. The moment plastic rotation curve calculated by IDEA StatiCa was compared with the measured one provided by test researchers (Figure 6.3). The difference between the slopes of the curves can be attributed to the stiffness degradation that the tested specimen underwent during the cyclic loading. Another comment that can be made is that since IDEA StatiCa employes bilinear material model, the strain hardening behavior could not be captured completely.

Table 6.3: Flexural moment strength of WUF-W moment connections calculated by IDEA StatiCa and AISC procedure (with respect to column face)

| Specimen No | AISC Flexural moment capacity (kips-in.) | IDEA StatiCa Flexural moment capacity (kips-in.) | IDEA/AISC |

| Baseline | 32,013 | 28,266 | 0.88 |

| Var-1 | 32,013 | 34,662 | 1.08 |

| Var-2 | 32,943 | 35,705 | 1.08 |

| Var-3 | 32,943 | 35,705 | 1.08 |

| Var-4 | 32,013 | 34,659 | 1.08 |

| Var-5 | 32,013 | 34,723 | 1.08 |

Figure 6.3: Moment (with respect to column centerline) plastic rotation comparison of WUF-W moment connection (baseline model)

Welded unreinforced flange-bolted web (WUF-B) moment connection

Flexural behavior of five tested WUF-B specimens (Lee et al., 1999) were investigated with a total of eight models using two different bolt types: 1) friction, 2) bearing. Flexural moment capacities of the specimens were calculated using IDEA StatiCa and following AISC design procedure and compared (Table 6.4). Since slip critical bolts can be designed as pretensioned bearing bolts if slip coefficient of faying surface is grater or equal to 0.30 according to AISC 341 (2016), the specimens containing slip critical bolts (e.g., baseline.SC, Var-2.SC, Var-3.SC) can be ignored in the moment strength comparison of IDEA StatiCa and AISC procedure. For the rest of the connections, differences between moment capacities calculated by IDEA StatiCa and AISC vary from -18% to -6% while the average difference is approximately 13%. The reason that IDEA StatiCa calculates more conservative moment strength than AISC procedure can be associated with the weak bond between beam web and column flange. A further examination can be conducted by replacing the shear tab with butt weld along the beam web and obtain a significant improvement in moment capacity following the same procedure in IDEA StatiCa.

For the baseline model, moment plastic rotation was obtained from IDEA StatiCa analysis and compared with the experimentally measured one (Figure 6.4). It should be noted that friction (slip critical) bolts are used for moment rotation analysis while bearing bolts are used for moment capacity analysis. The difference between the curves can be associated with the data extraction process. Since the measured moment rotation curve was extracted from the figure provided in the test report, small errors are inevitable. The difference of post-yielding behavior can be explained with the bilinear material model used by the software.

Figure 6.4: Moment (with respect to column centerline) plastic rotation comparison of WUF-B moment connection (baseline model)

Table 6.4: Flexural moment strength of WUF-B moment connections calculated by IDEA StatiCa and AISC procedure (with respect to column face)

| Specimen No | AISC moment strength (kips-in.) | IDEA StatiCa moment strength (kips-in.) | IDEA/AISC |

| Baseline.SC | 7,410 | 6,425 | 0.87 |

| Var-1 | 11,831 | 11,091 | 0.94 |

| Var-2.SC | 15,974 | 12,116 | 0.76 |

| Var-3.SC | 15,538 | 11,779 | 0.76 |

| Var-4 | 24,286 | 20,986 | 0.86 |

| Baseline.X | 7,410 | 6,482 | 0.87 |

| Var-2.X | 15,974 | 13,063 | 0.82 |

| Var-3.X | 15,538 | 13,165 | 0.85 |

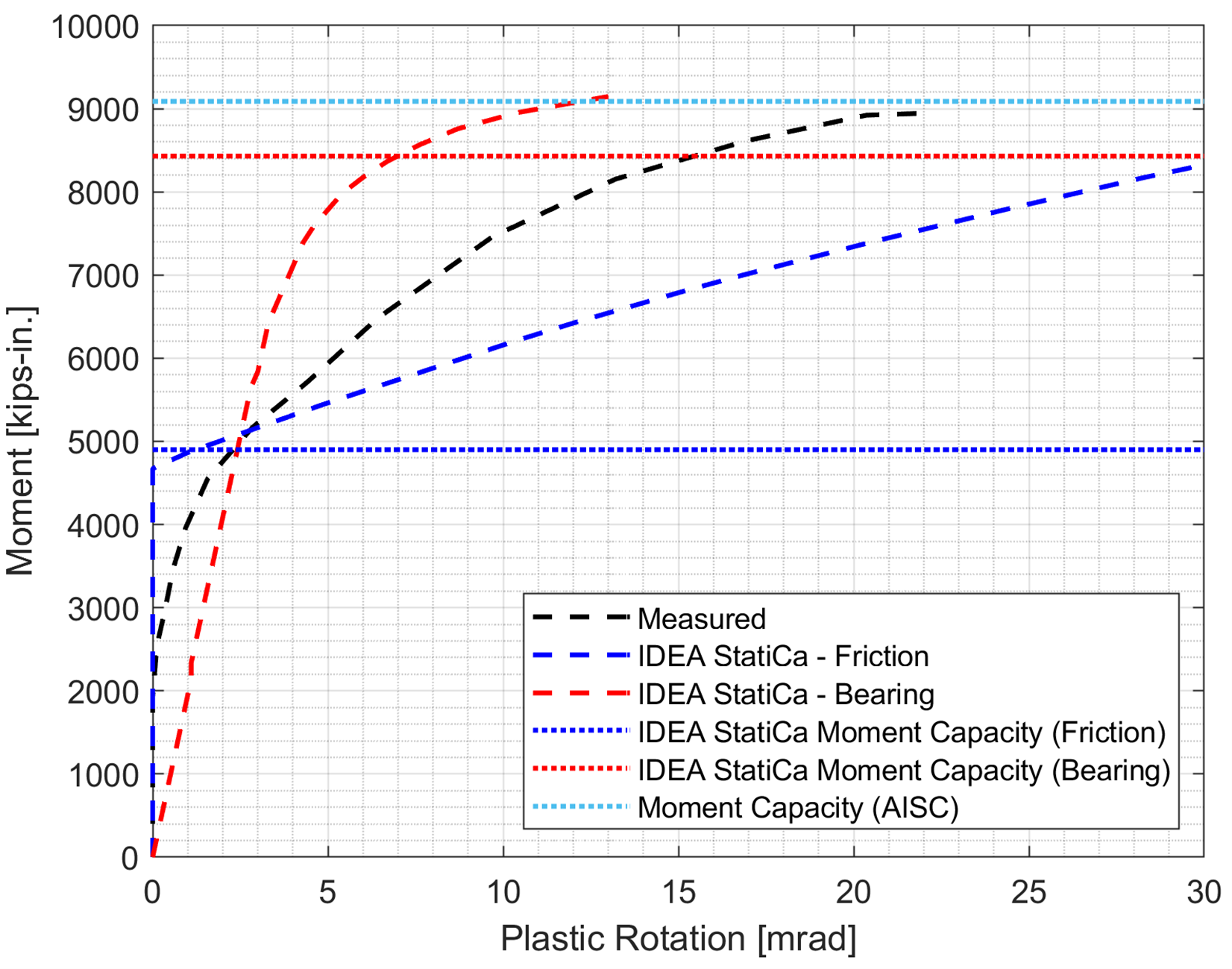

Double-tee moment connection

Six tested double-tee connections were examined following AISC design procedure and using IDEA StatiCa. Their moment capacities were calculated, and the results were compared.

Differences between the results vary from -9% to +7% while the average difference is approximately 3% (Table 6.5). Also, the failure modes were estimated reasonably well. Moment rotation analysis was performed through IDEA StatiCa and ABAQUS using two different bolt types (e.g., bearing, friction) since tension-control bolt type is not available in IDEA StatiCa. The curves were compared with the experimentally obtained one performed by Leon (1999) for the baseline model (Figure 6.5). It is observed that moment plastic rotation curve of the test specimen falls between those calculated from IDEA StatiCa analyzes for friction and bearing bolts as expected. Additionally, prequalification checks outlined in AISC 358 were performed for the specimens. For the baseline model, capacity design analysis was performed in IDEA StatiCa, and compared with the one obtained following AISC procedure. It can be concluded that IDEA StatiCa is very capable of calculating moment capacity and determining failure mode of double-tee moment connections. Moreover, it can be added that capacity analysis (e.g., CD) is capable of determining whether the connection has enough strength capacity when plastic hinge occurs in both beams as required by AISC 358 for seismic connections.

Table 6.5: Flexural moment strength of double-tee moment connections calculated by IDEA StatiCa and AISC procedure (with respect to column face)

| Specimen No | AISC moment strength (kips-in.) | IDEA StatiCa moment strength (kips-in.) | IDEA/AISC |

| Baseline | 8,749 | 8,090 | 0.92 |

| Var-1 (Mill) | 4,398 | 4,702 | 1.07 |

| Var-1 (Coupon) | 5,246 | 5,278 | 1.01 |

| Var-2 (Mill) | 4,684 | 4,741 | 1.01 |

| Var-2 (Coupon) | 5,787 | 5,499 | 0.95 |

| Var-3 | 8,802 | 8,013 | 0.91 |

| Var-4 | 8,802 | 8,013 | 0.91 |

| Var-5 | 7,880 | 7,630 | 0.97 |

Figure 6.5: Moment (with respect to column centerline) plastic rotation comparison of double-tee moment connection (baseline model)

Overall, there is good agreement among the moment capacities and failure modes obtained from tests, IDEA StatiCa analysis, and AISC design procedure. The recommendations to further improve the software are listed below:

- A new bolt type for tension-controlled/preloaded bolts can be developed and provided to users in addition to bearing and friction bolt types.

- Forces to be applied with “loads are in equilibrium” options can be calculated from IDEA StatiCa for different element lengths and boundary conditions according to user’s preferences. In this way, an analysis can be performed for desired condition without other software or additional hand calculation. With the current IDEA StatiCa version (i.e., v22), to calculate moment capacity of test specimens, the forces at the connection were calculated using SAP2000 by representing test setup conditions (e.g., element lengths, boundary conditions), then those calculated forces were applied in IDEA StatiCa using “loads are in equilibrium” option.

- Incremental loading can be applied automatically and systematically by IDEA StatiCa and the moment capacity can be provided without a need of adjusting the loads and re-run

- Prequalification checks can be performed by IDEA StatiCa

- A better meshing tool can be adapted to the software

- The representation of moment rotation curve can be improved/enriched by providing users tools to adjust font, color, and size of plot.

- Some symbols need to be corrected/adjusted for the American users (e.g., θ instead of ϕ for the rotation according to AISC)

Read the full verification example article on the Double-tee moment connection