Connection pre-design

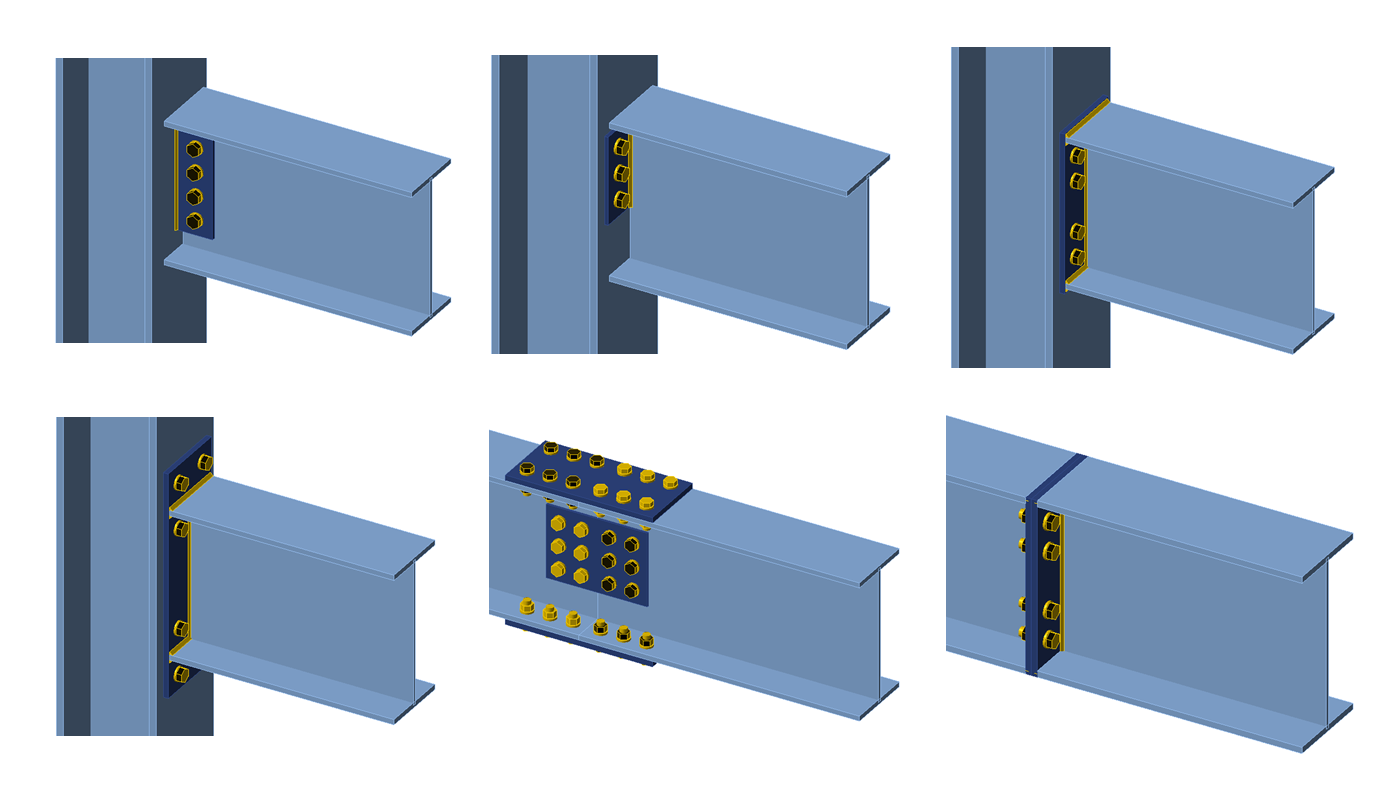

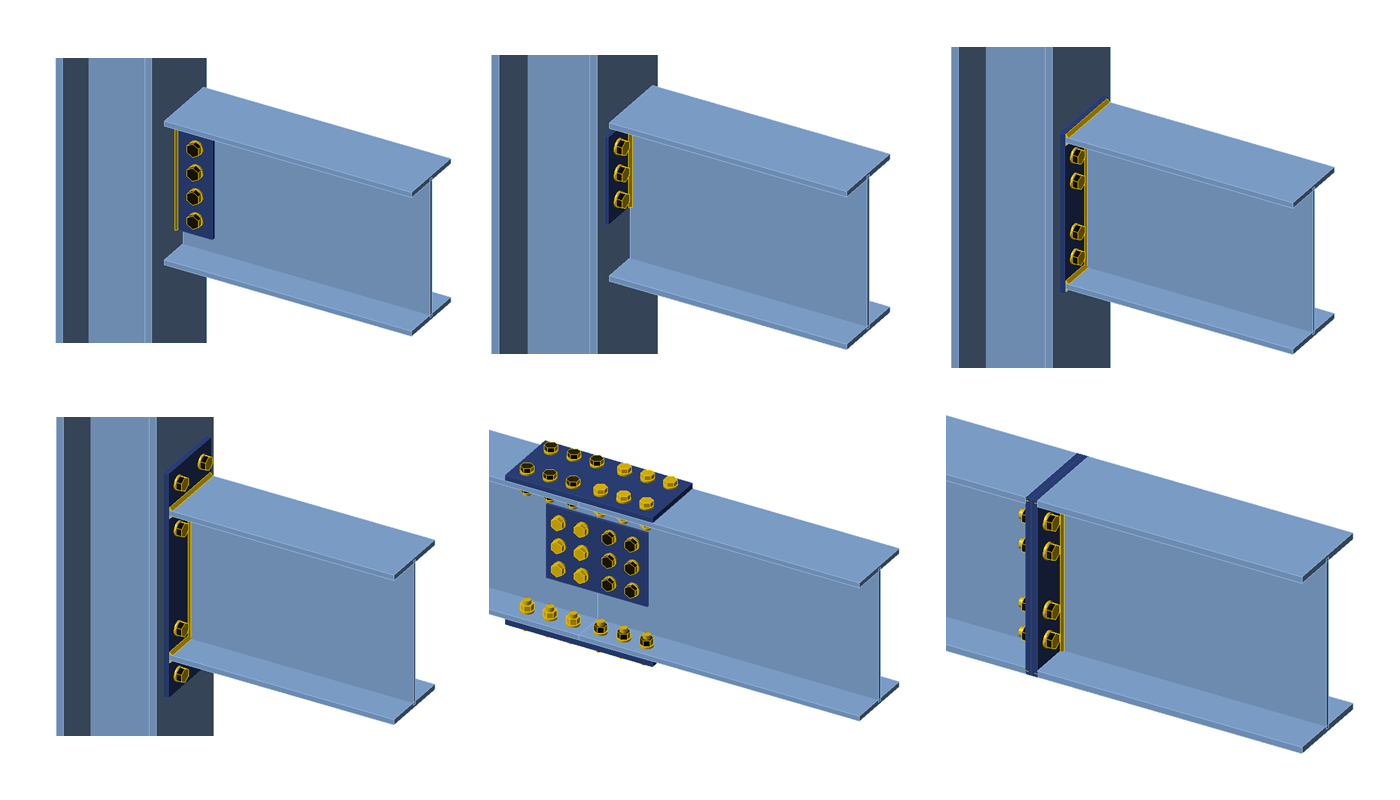

The feature is in its early stage and was primarily implemented for I-shaped cross-sections and these most common manufacturing operations:

- Fin plate

- Splice

- Shear endplate

- Flush and extended endplate

- Welds

How does it work?

Pre-design reads input data from the properties table of the given manufacturing operation and then creates a suggested initial design. In general, material and geometrical data of the connected members, bolt assembly, and weld data are all read as inputs for the process of pre-design. As a result (output), plate thickness, weld sizes, number, and layout of bolts are generated.

The resulting design is roughly based on the resistance of the connected cross-sections or plates. The percentage of this resistance can be modified in pre-design settings (top ribbon). A higher percentage will yield more robust designs.

There are several other preferences you can change in Settings, including preferred dimension increments for plate thicknesses, weld size, and bolt spacing.

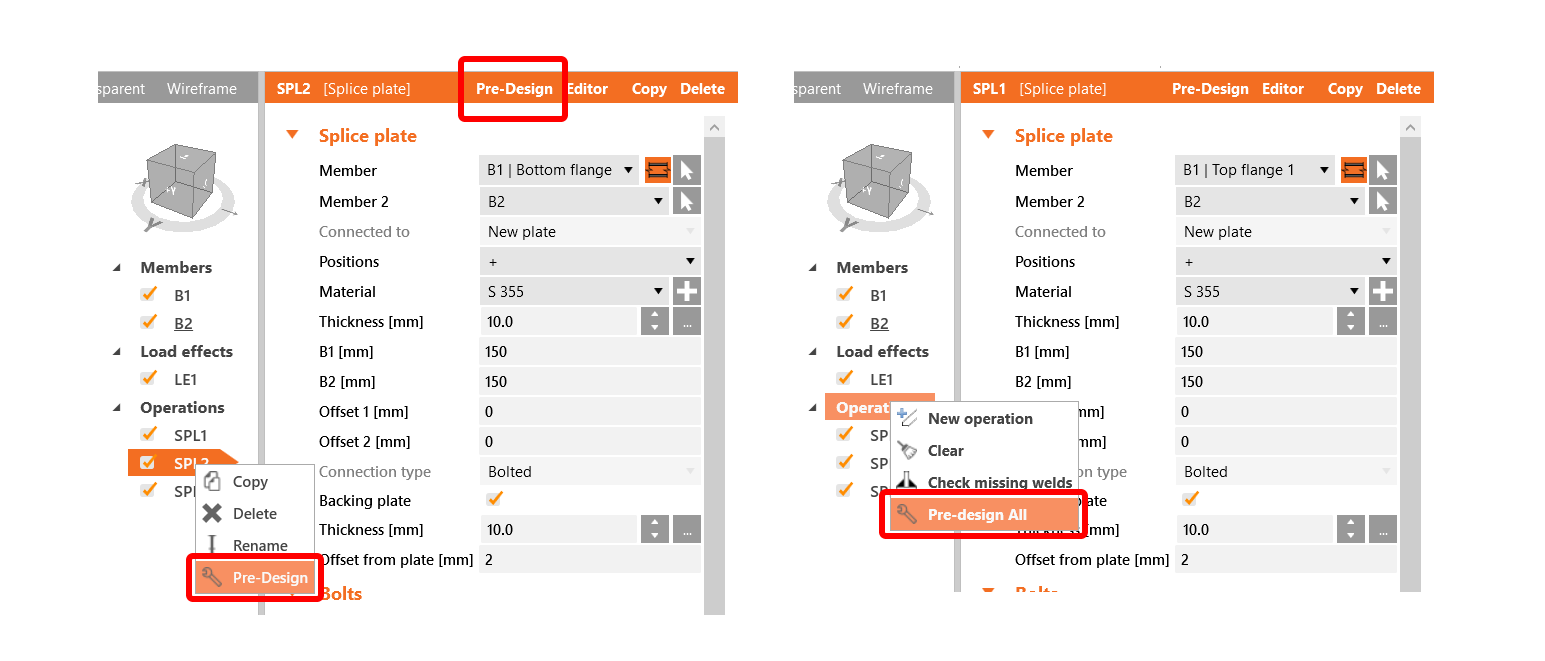

In case a given operation is supported, you can call pre-design by right-clicking the operation name in the tree of operations, or by clicking the button in the orange tab at the top of the operation property grid. Pre-design is also called automatically on creating a new operation. It is also possible to get the pre-design in batch for all supported operations just by right-click on Operations in the tree.

Available in Expert and Enhanced edition.