Crane girder in a paper factory

About the Project

In Sweden, a major paper factory required the design and analysis of crane girders capable of handling heavy-duty industrial operations. The structural design had to accommodate the demands of several types of crane with capacities of up to 30 tons, factoring in self-weight and operational stresses. The project included designing end plate splices and end support connections, and analyzing the structure for long-term durability under significant cyclic loading.

Authors of the project

TIM Global Engineering, based in Serbia, specializes in structural engineering, steel detailing, and connection design, delivering projects with precision and efficiency from concept to installation. Their multidisciplinary team, including structural, civil, and mechanical engineers, is supported by advanced technologies like Building Information Modeling (BIM) and Finite Element Analysis (FEA). With rigorous quality assurance processes and reviews by chartered engineers, the firm ensures projects are error-free, on time, and on budget. Their expertise spans industrial buildings, aircraft docks, platforms, and more, combining innovative tools like IDEA StatiCa with global experience to meet complex design challenges while upholding a strong reputation for accuracy and reliability.

Engineering Challenges

The main challenges revolved around achieving reliable connections that met stringent fatigue resistance requirements while ensuring seamless assembly and efficient material usage. The project also had to adhere to evolving Eurocode standards and incorporate preloaded bolt considerations to address fatigue-specific stress ranges.

Solutions and Results

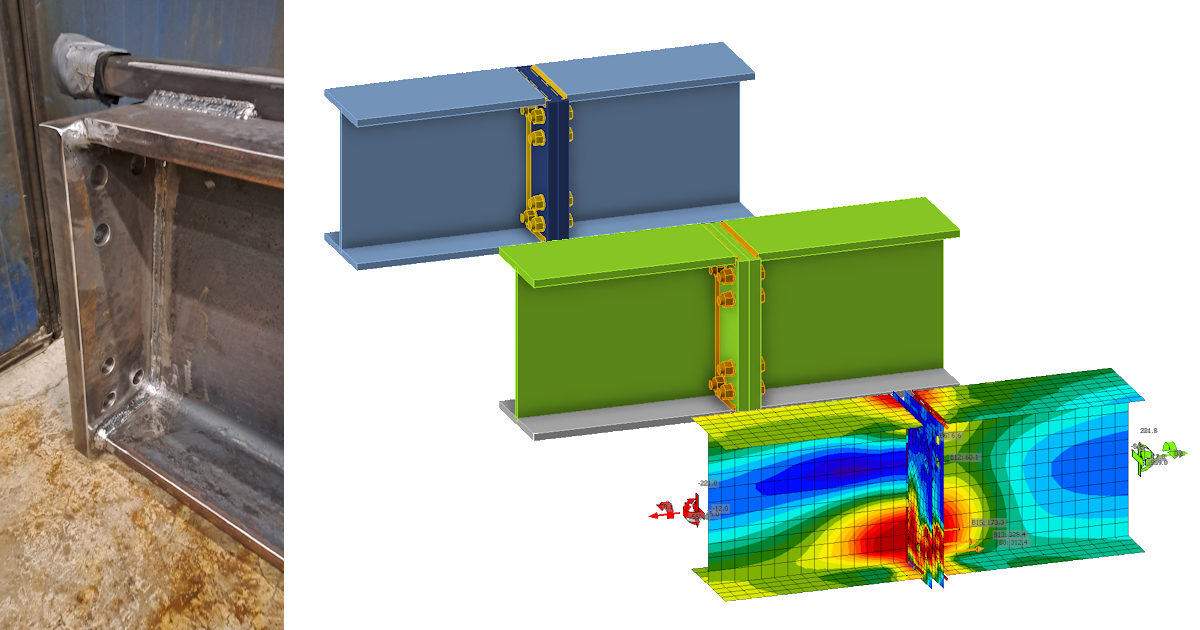

The workflow began with global structural analysis in RFEM, exporting forces and geometrical details directly into IDEA StatiCa. The design process then included multiple iterations to refine connection geometries and validate fatigue performance. Fatigue analysis proved crucial for ensuring durability, especially for crane girders supporting bridge cranes with heavy cyclic loads.

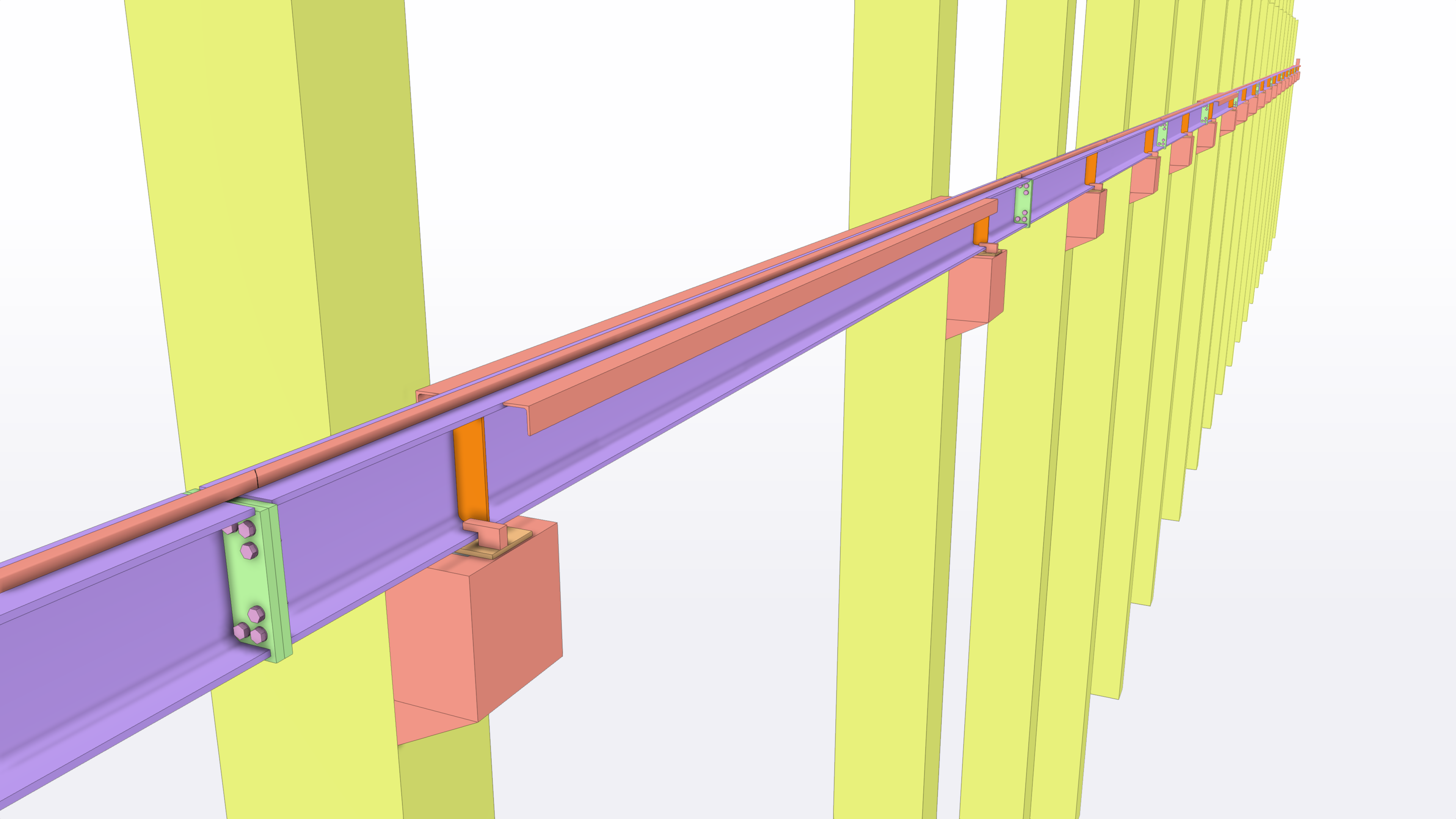

The project involved five different types of crane girders, each designed to meet specific operational and structural requirements. Some girders were anchored to concrete columns, while others were supported by steel columns, depending on their location within the factory. To accommodate varying operational loads, the design included multiple splice connections tailored to different load levels – ranging from low-load splices to medium and heavy-load splices, each with distinct geometrical and material considerations.

Serbia

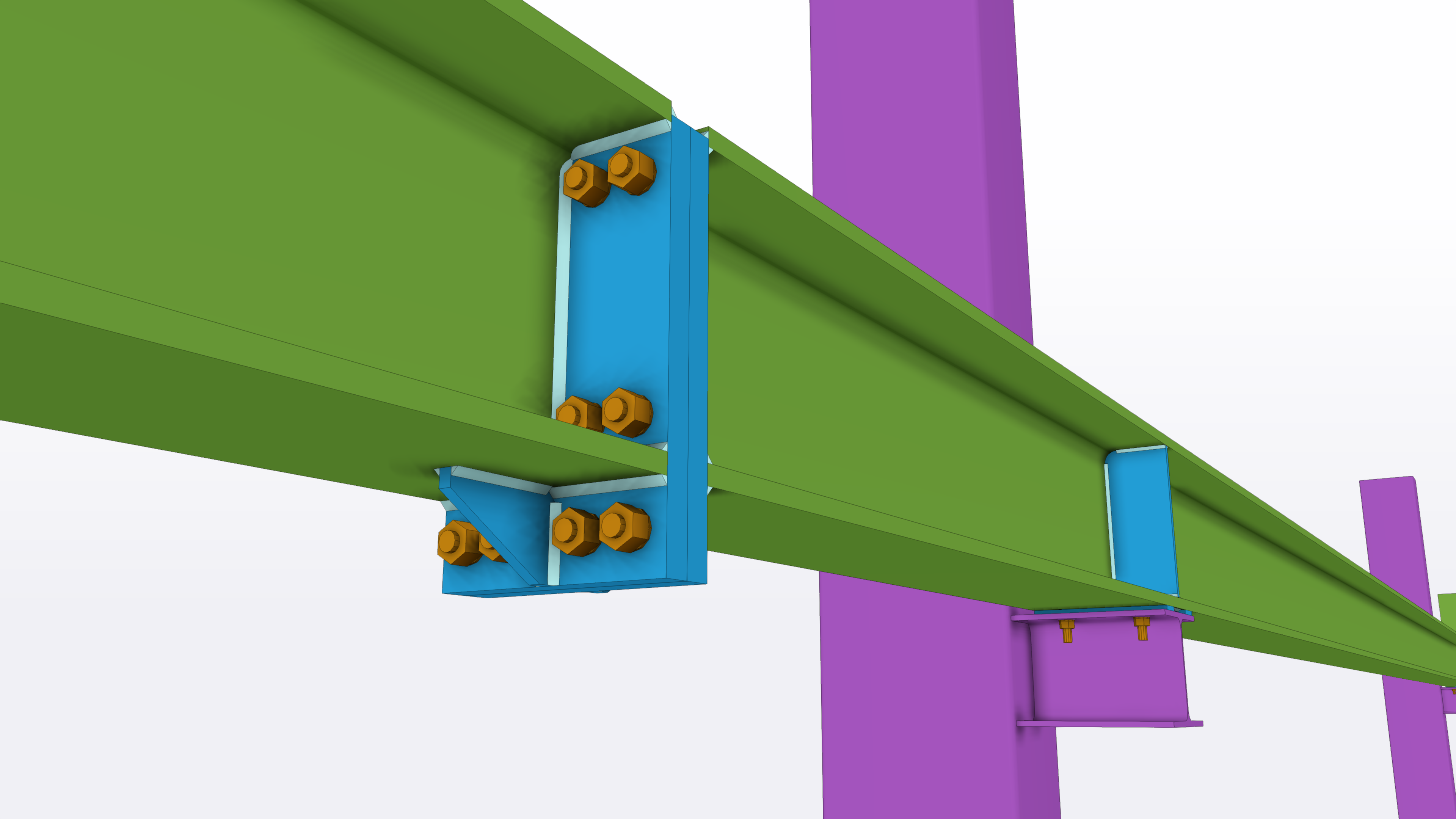

\[ \textsf{\textit{\footnotesize{Model of the medium-load girder}}}\]

\[ \textsf{\textit{\footnotesize{Splice connection on the medium-load girder}}}\]

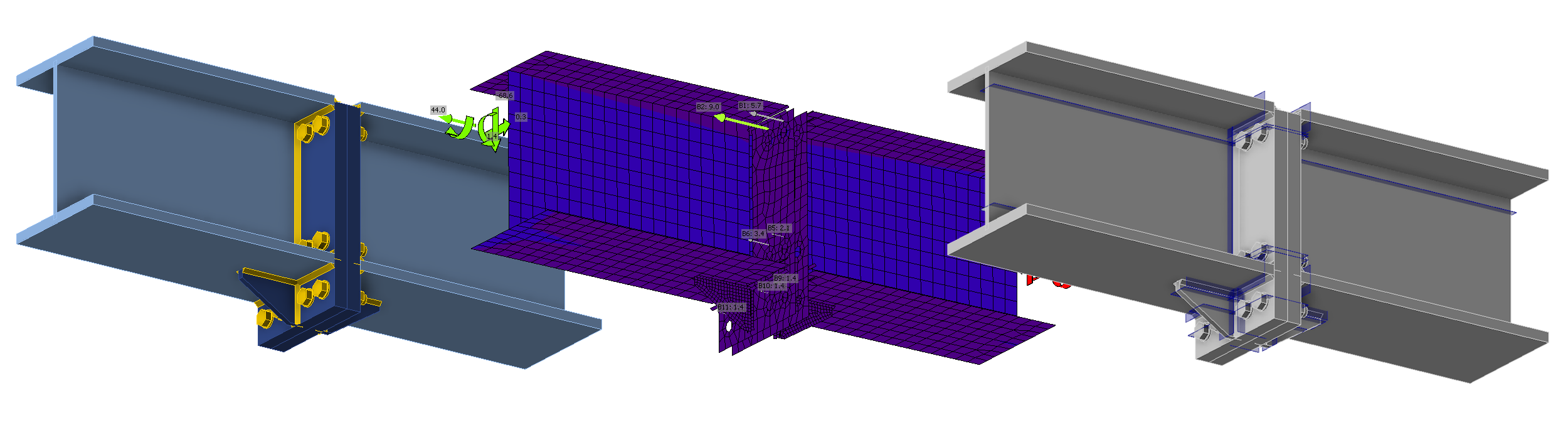

The girder designed for the heaviest load carried two cranes, each with a capacity of 30 tons. The cranes themselves had a self-weight ranging between 20 and 30 tons, resulting in significant cyclic stresses on the structure. To meet these demands, the girder was specified with an HEA500 profile, offering the necessary strength and stiffness. Advanced fatigue analysis was performed using IDEA StatiCa Connection, leveraging stress range calculations to ensure the design could withstand prolonged cyclic loading while maintaining structural integrity.

\[ \textsf{\textit{\footnotesize{Model of the heavy-load girder}}}\]

\[ \textsf{\textit{\footnotesize{Splice connection on the heavy-load girder}}}\]

Serbia

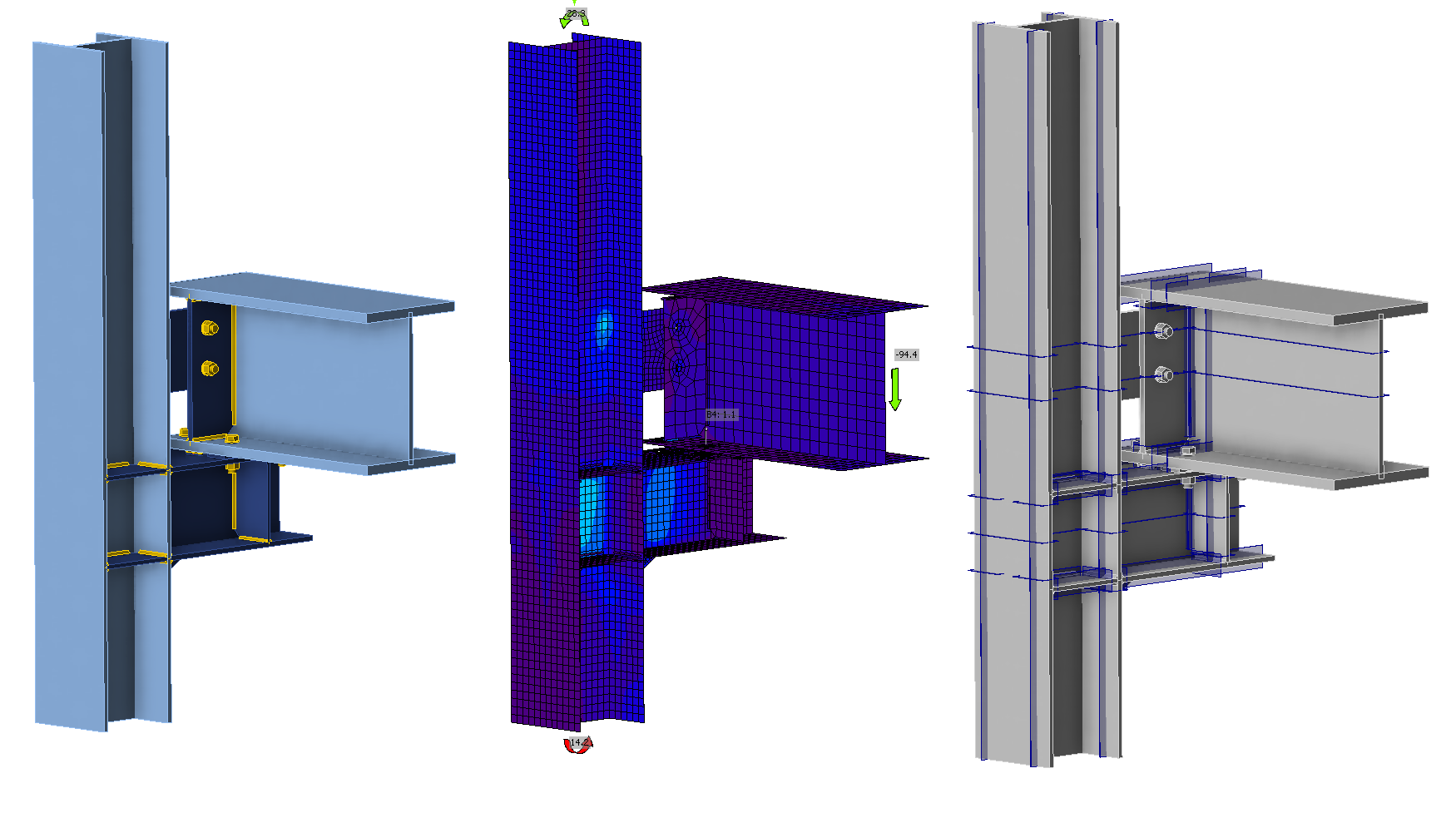

\[ \textsf{\textit{\footnotesize{End support of the crane girder at the steel column}}}\]

Conclusion

The successful design and analysis of the crane girders for the Swedish paper factory highlight the critical role of advanced engineering tools in tackling complex structural challenges. By leveraging IDEA StatiCa Connection, the team at TIM Global Engineering was able to deliver precise, fatigue-resistant connections tailored to varying load requirements, from light to heavy-duty operations. The seamless integration of global analysis and connection design, coupled with robust fatigue analysis capabilities, ensured compliance with Eurocode standards while optimizing workflow efficiency. The result is a durable, high-performing structure capable of supporting the factory's demanding operations for years to come, demonstrating the effectiveness of modern software in delivering innovative and reliable engineering solutions.

Probeer IDEA StatiCa gratis uit

OTHER CASE STUDIES