Failure of long prestressed precast concrete beams

A bending or an excessive deflection around the weak-axis occurrence of a slender precast prestressed beam or even the collapse of a prestressed precast concrete girder bridge on a construction site during the lifting stage is not a rare misfortune. But is it really still happening nowadays with all the safety codes, guidelines, and previous engineering experience? Yes, it is. How come? What is the problem?

Lateral instability of long prestressed beams

Precast concrete beams, or girders are used in a wide variety of projects, typically industrial halls, hypermarket stores, warehouses, or girder bridges made of precast prestressed concrete. Several technological advances, like materials used, more efficient cross-section shapes, and larger prestressing strands enable reaching larger spans. Because of the increase in span, the total weight of such beams also increases, sometimes making the transport and handling stages the critical load cases in the structural design, as depicted in figure [3].

The common strategy to overcome this issue is to minimize the self-weight of the beams by reducing the width of the flanges. Nevertheless, this also reduces the weak-axis stiffness and torsional stiffness of the element, amplifying the risk of lateral instability. [1]

The reported accidents and damages due to lateral instability are usually associated with eccentricities that activate second-order effects during transient loading situations (lifting, transport, and support on bearings). Typical sources of these eccentricities are fabrication tolerances, variations in the lateral positioning of strands, local cracking, creep and shrinkage sweep, and sun heating on one side, causing the girder to bow. Since prestressed concrete beams were assumed to have enough margin of weak-axis stiffness, limited attention has been traditionally paid to the phenomenon. [1]

Accidents of long prestressed precast concrete beams

Kyiv’s 1965-built Dehtiarivskyi Bridge, which closed for renovation on June 13, 2023, collapsed [2]. Apparently, after six beams had already been mounted, workers started installing the seventh one, and the beam lost its stability, pushing the rest of the beams, and everything collapsed. Fortunately, there were no casualties, but of course, there were huge financial damages.

Another example is failure during the lifting phase. A 45.6 m long prestressed precast concrete girder with an I-shape constant cross-section with a height of 2 m and an upper flange width of 1.2 m. Imagine this: a deformed shape after the first lifting operation and a drastic increase in the lateral displacement of up to 300 mm (L/150). The girder was placed again on the ground to evaluate possible damage. After the inspection, vertical cracks were observed at the left upper flange. Crack widths were over 0.4 mm, which should have been repaired in order to comply with the durability requirements if the element was to be finally accepted.

Then a second intent of lifting was performed. However, it showed a lateral sweep of more than L/400, which meant this beam was unable to recover its original shape. This was probably caused by plastic deformation that occurred during the lifting operations. Thus, this beam was rejected, and a new girder was produced and transported to the job site. [1]

Safe slender prestressed precast concrete beam design

How can we prevent such accidents and damage? Do we stop designing long prestressed concrete beams? Of course not, it would have been a step backward and such a shame (the author is a big prestressed concrete fan)! For a structural engineer, it is not an easy task to deliver a safe, economical design in minutes.

And in this case, I am afraid that pen and paper are not enough. In my recent engineering practice, I always wished there had been software that could help me with the complex calculations involved in lateral torsional buckling (LTB) of slender prestressed beams. Naturally, I didn't want to spend my youth entering input values and interpreting the results in halfway programs.

The solution for lateral torsional buckling

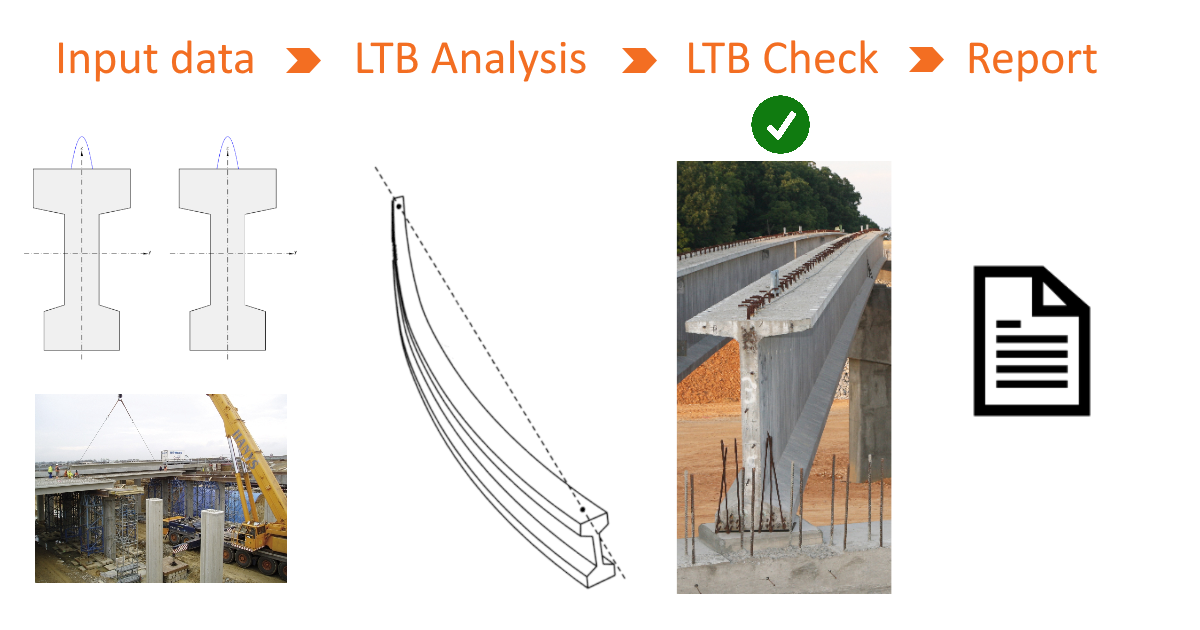

Good news, there is IDEA StatiCa coming with complex analysis for lateral torsional buckling (LTB) of long precast prestressed concrete beams. All this is available in one tool which is easy to use, has clear results, and automatically generates reports. Just follow the typical IDEA StatiCa Beam workflow:

- Geometry: cross-section, span information, prestressing tendons, construction stage history are already defined in the Beam app for the global analysis and design. All data is automatically taken into account.

- Lateral stability tab: define detailed input data about lifting, transportation and other construction stages such as initial imperfection, sling details, final support types, etc. All of these ones impact LTB analysis.

- Run LTB analysis: i.e.; materially and geometrically nonlinear analysis with initial imperfections. The advanced method behind, not simplified methods or formulas.

- Results: the outputs of the LTB analysis are reactions, internal forces, and deflection

- LTB check: so far, manual input to the RCS app is available. After LTB analysis is run, go to detailed results (RCS app) and save as new file, input additional internal forces due to buckling to governing ultimate and serviceability combination and run all the checks.

Note: Automatic input of LTB results to checking combinations will be developed soon. - Report: Generate accurate reports with automated code-checks and customizable outputs, saving you time and reducing the risk of errors.

Find more technical details about the LTB analysis and checks here.

Last word

Ensure beam safety at every manufacturing and construction stage with integrated LTB stability checks, covering all conditions from storage, through transportation to lifting. Stop worrying or even avoiding the designs of slender prestressed precast concrete beams because they are at risk of losing their lateral stability. Today, you can be confident by having IDEA StatiCa on your side!

Sources

[1] A. de la Fuente, J.M. Bairán, S.H.P. Cavalaro, Case Study of Failure of Long Prestressed Precast Concrete Girder During Lifting, Engineering Failure Analysis, Volume 100, 2019, Pages 512-519, ISSN 1350-6307, https://doi.org/10.1016/j.engfailanal.2019.02.061, (https://www.sciencedirect.com/science/article/pii/S1350630717302236)

[2] Available online https://english.nv.ua/nation/photos-of-collapsed-kyiv-s-dehtiarivskyi-bridge-50357382.html

[3] Available online https://www.prefa-praha.cz/tycove_prvky/