AISC 358 Prequalified Moment Connection Checks

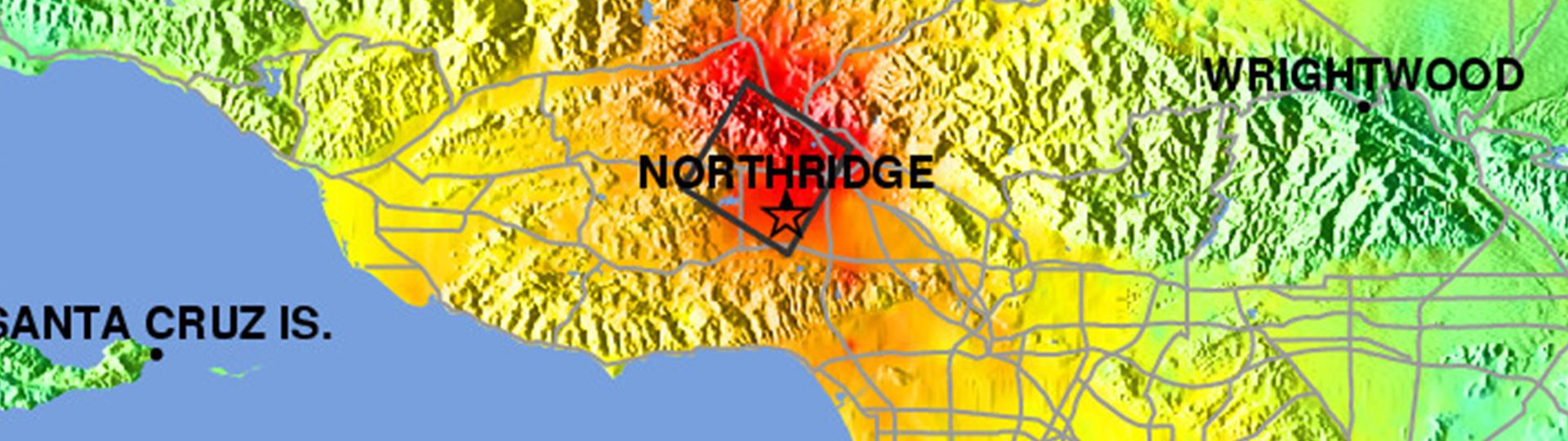

Let’s start by talking about the origin of the prequalified connections. After the 1994 Northridge earthquake in California, research regarding the seismic response of structural steel building systems significantly increased due to the creation of the SAC Joint Venture with “the goal of developing reliable, practical, and cost-effective guidelines and standards of practice for the repair or upgrading of damaged steel moment frame buildings, the design of new steel buildings, and the identification and rehabilitation of at-risk steel buildings.”

The SAC joint venture was funded by the US Federal Emergency Management Agency (FEMA) (https://www.sacsteel.org/project/mission.html)

The findings from the Northridge earthquake were that several steel moment frame buildings experienced brittle fractures that started at the welded beam flange-to-column flange joints of moment connections. The fractures exhibited a variety of patterns and sometimes extended into and across column panel zones.

These unexpected brittle fractures were quite different from the expected performance of ductile beam flexural yielding in plastic hinge zones. Where they occurred, these brittle fractures prevented the formation of ductile plastic hinge zones. They resulted in frame behavior substantially different from that upon which the design requirements for these systems were based.

The Connection Prequalification Review Panel (CPRP) was created by AISC in 2001 to develop a connection prequalification standard. The panel, composed of engineers, researchers, fabricators, and building officials, reviewed testing and other research data by SAC and others to publish the first edition of AISC 358 in 2005.

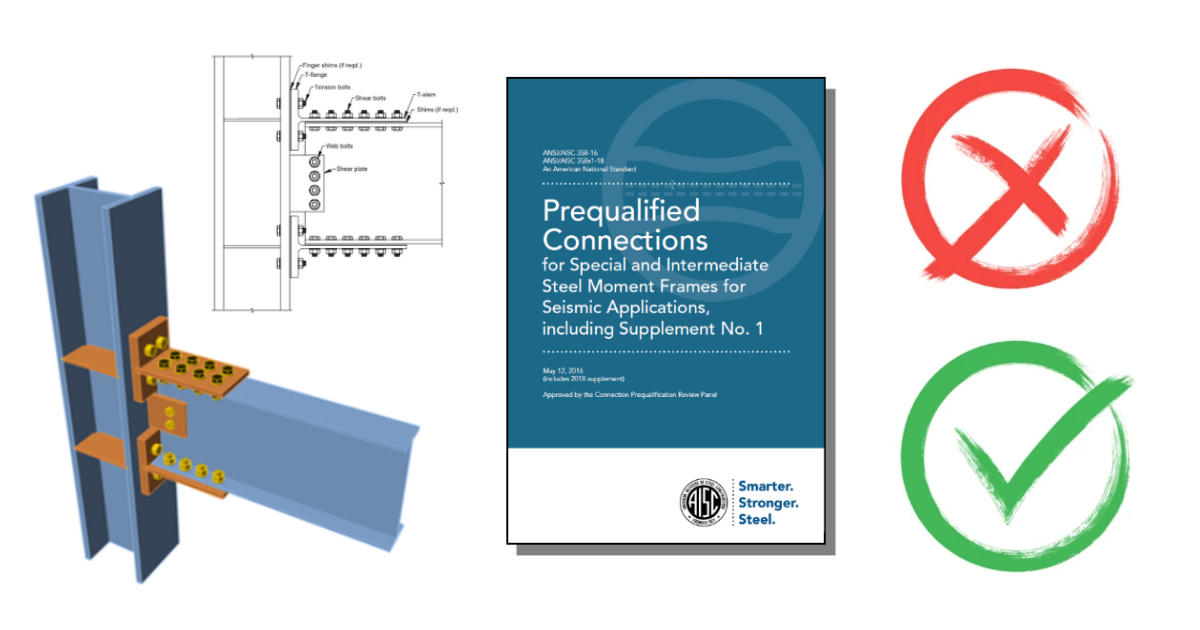

This first edition included prequalification data and design procedures for three connection types. Since this 2005 publication, the CPRP has continued to review data for additional connection technologies, and the latest and current AISC 358 now contains ten types of prequalified connections, which include several patented connections:

- Reduced Beam Section (RBS)

- Bolted Unstiffened and Stiffened Extended End-plate

- Bolted Flange Plate (BFP)

- Welded Unreinforced Flange-Welded Web (WUF-W)

- Kaiser Bolted Bracket (Patented)

- ConXtech ConXL (Patented)

- Sideplate (Patented)

- Simpson Strong-tie Strong Frame (Patented)

- Double-Tee

- Slotted Web (Patented)

What are these unique connections?

Based on the findings of the SAC Joint Venture, the main reasons associated with brittle fractures were that the connection geometries had large stress concentrations and limited ability to yield, the weld filler metals used had limited ductility, different yield strengths of beams and columns resulting in unanticipated zones of weakness in connection assemblies, and welding practices weren’t following the AWS Structural welding code.

“Following the SAC Joint Venture recommendations, the AISC Seismic Provisions require that moment connections used in special or intermediate steel moment frames be demonstrated by testing to be capable of providing the necessary ductility.

Two means of demonstration are acceptable. One means consists of project-specific testing in which a limited number of full-scale specimens, representing the connections to be used in a structure, are constructed and tested by a protocol prescribed in Chapter K of the AISC Seismic Provisions. Recognizing that it is costly and time-consuming to perform such tests, the AISC Seismic Provisions also provide for the prequalification of connections consisting of a rigorous program of testing, analytical evaluation, and review by an independent body, the Connection Prequalification Review Panel (CPRP).

Connections contained in this Standard have met the criteria for prequalification when applied to framing that complies with the limitations contained herein and when designed and detailed by this Standard.” (AISC 358 Commentary introduction)

In summary, connections prequalified under the AISC 358 Standard are intended to withstand inelastic deformation primarily through controlled yielding in specific behavioral modes. To obtain connections that will behave in the indicated manner, proper determination of the strength of the connection in various limit states is necessary. The strength formulations contained in the LRFD method are consistent with this approach."

What's the current design process of an AISC prequalified connection?

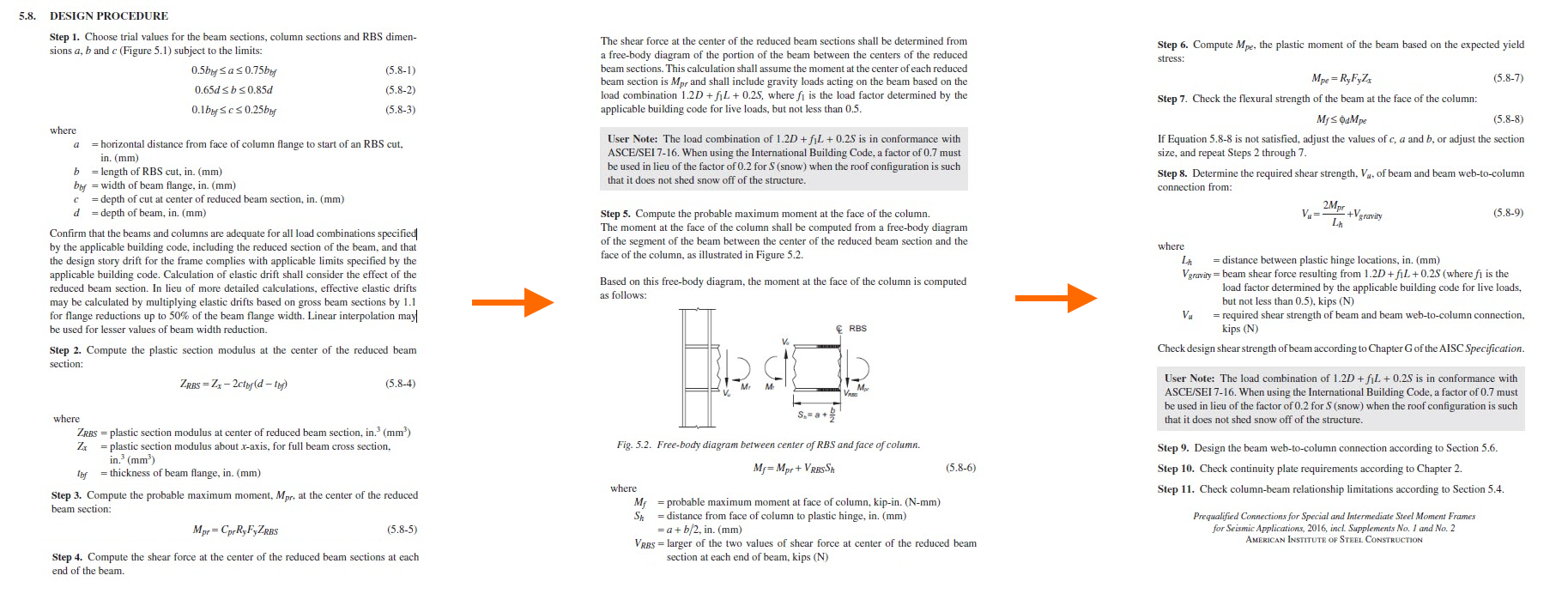

AISC 358 contains a chapter dedicated to each type of prequalified connection and all the needed details to comply with the code. In each chapter, all the design limitations are stated, and a design process is presented.

The design of a connection is a step-by-step process where, depending on the connection, you start by choosing the geometry via trial and error. Next comes calculations of the plastic section modulus, the maximum probable moment at the expected plastic hinge, shear force, and the plastic moment of the beam are required to be compared against the strength of the beam.

The main idea of the design process is to design a strong column-weak beam system. Thus, you must calculate the maximum moment at the controlled plastic hinge location, ensuring the beam fails before the connection and column when a seismic event occurs.

The patented connections have different methods of design, and an engineer interested in using these connections needs to reach out to the patent holder to understand how the design is completed.

Study on prequalified connections

In 2023, Ohio State University (OSU) worked on a study to verify the reliability of the CBFEM used in the IDEA StatiCa software when analyzing different types of seismic prequalified steel connections.

This project aimed to evaluate the behavior of seismic moment connections obtained from the IDEA StatiCa software – considering load resistance, rotation capacity, and moment-rotation response.

The results were compared against the tried-and-true methods: AISC equations, ABAQUS (FEA software), and the results of laboratory full-scale tests.

The study demonstrated that IDEA StatiCa is a dependable tool for calculating moment capacities and predicting failure modes across different steel connections.

Read here for more about the OSU study on prequalified connections.

How IDEA StatiCa integrates into the design process of prequalified connections

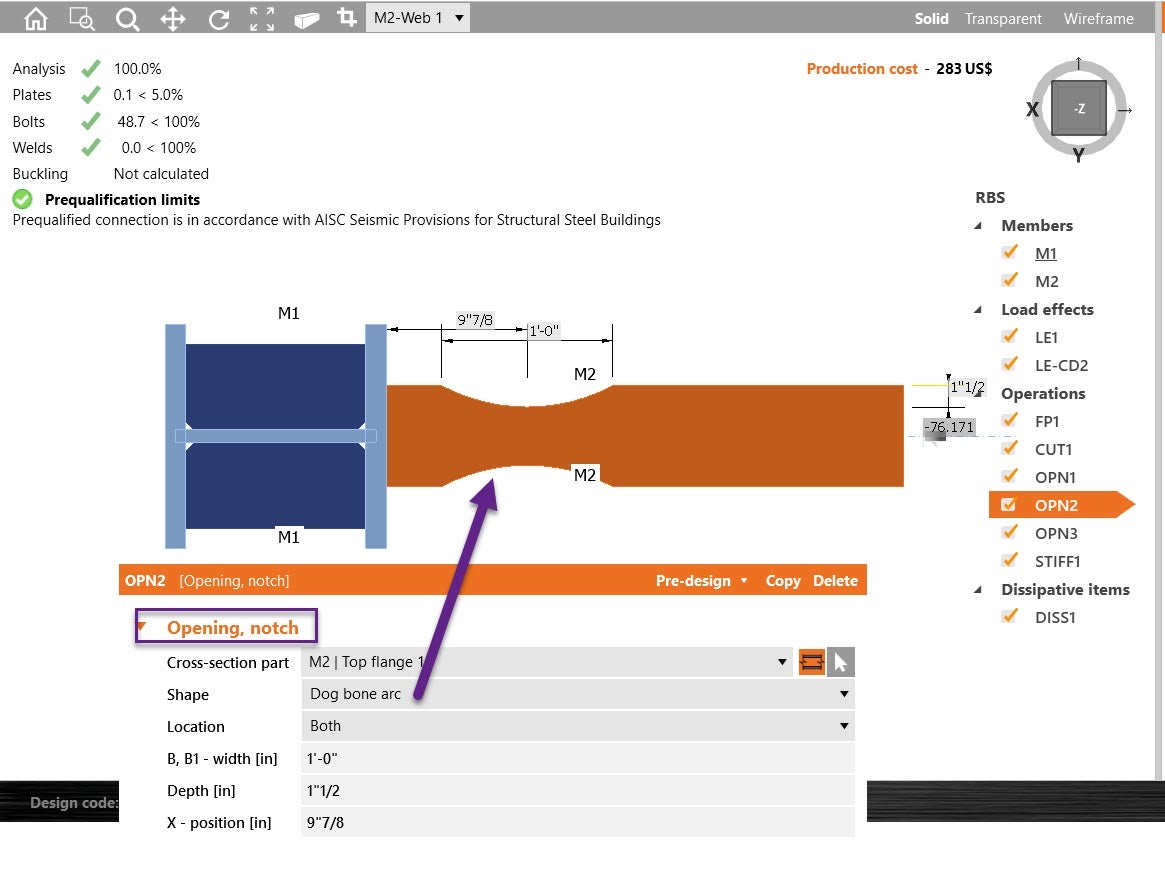

In IDEA StatiCa, it was always possible to model prequalified connections, and the modeling wasn’t too tricky as there are simple operations that ease the modeling, for instance:

Openings (to model the flange cutouts):

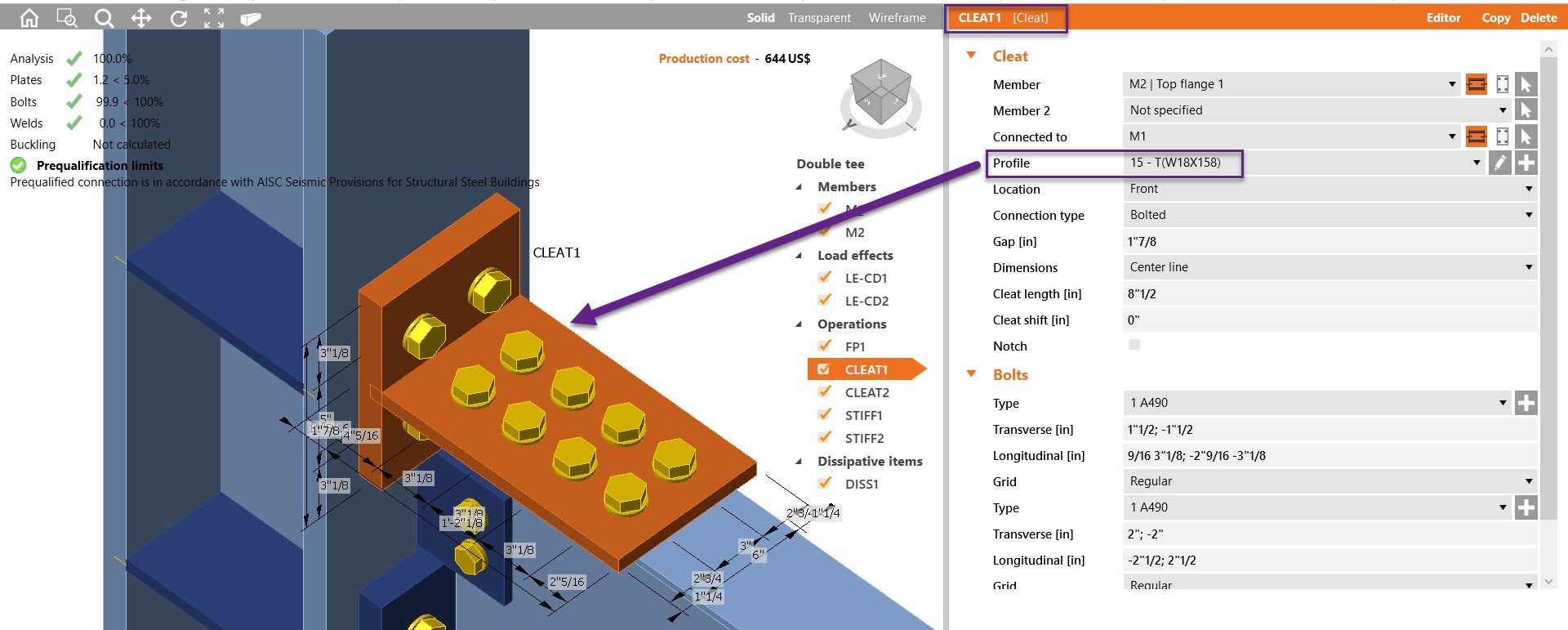

Cleat operation to add tee sections on both sides:

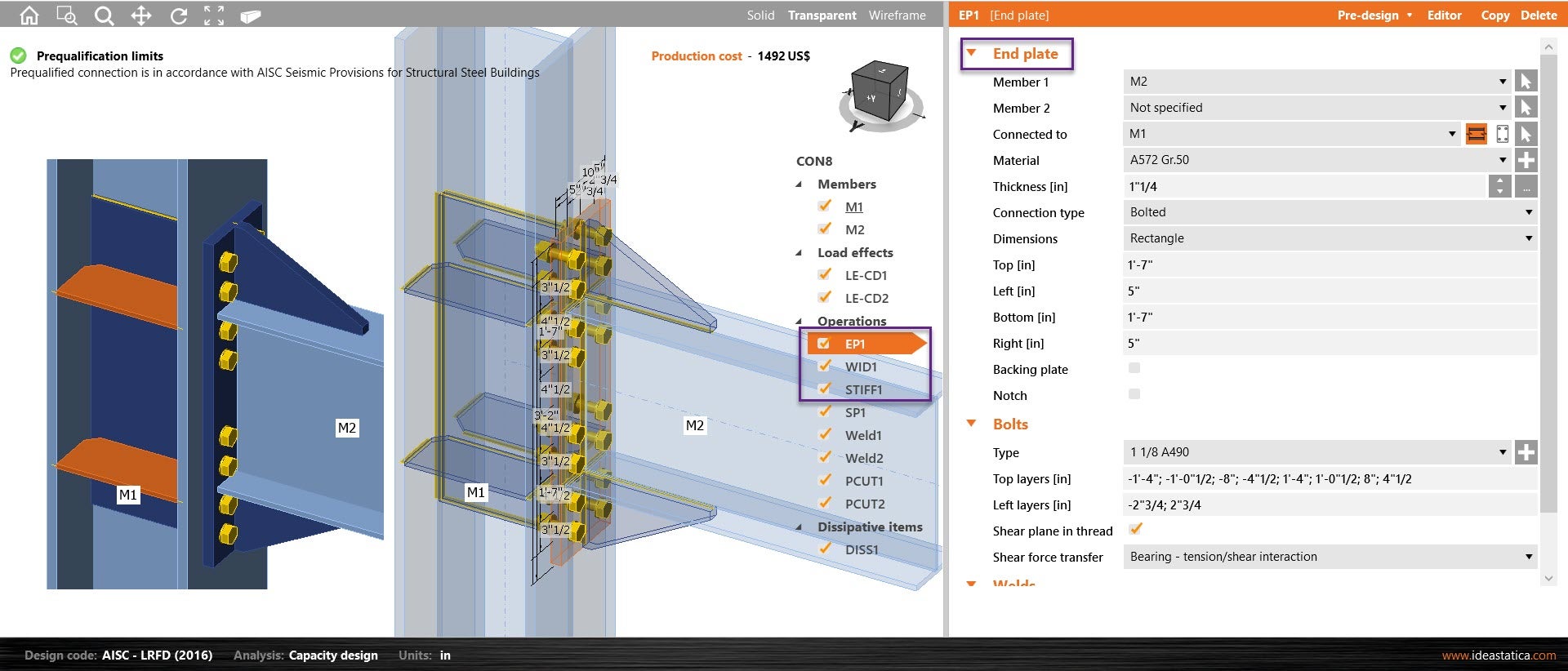

End plate, stiffeners, wideners:

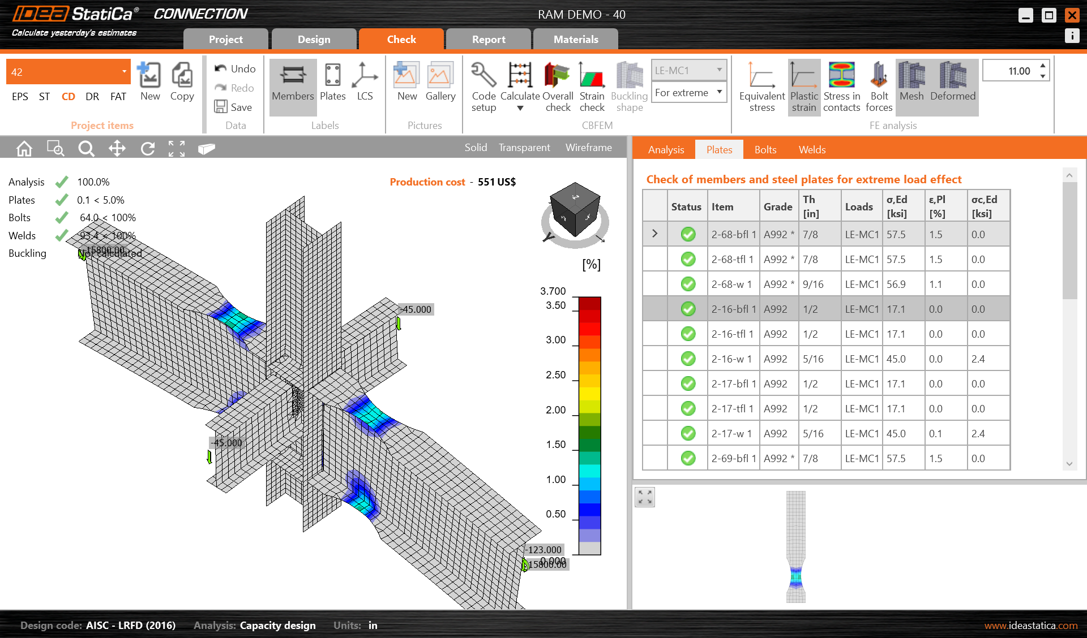

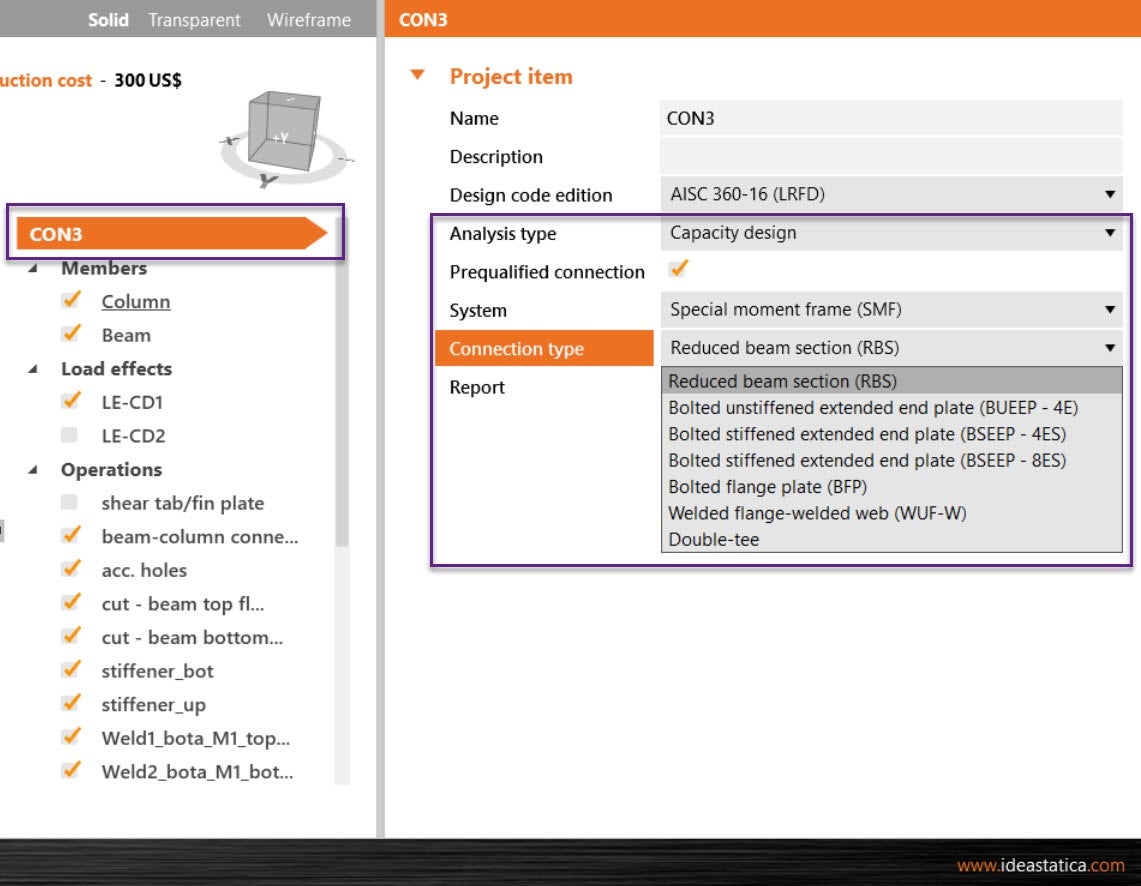

Once you have modeled the connection, the Capacity Design analysis type is used to confirm that the planned plastic hinge is happening where it was designed to occur. For instance, the plastic hinge for an RBS connection is intended to happen in the reduced section of the beam; in a Bolted flange plate, the intention is to have the plastic hinge near the end of the flange plates.

So, when you select capacity design analysis in IDEA StatiCa, a dissipative member where the plastic hinge is meant to form needs to be assigned. The connection and the column are non-dissipative elements which must remain without significant deformations. The beam is loaded as necessary to create the plastic hinge in the beam with probable yield strength and by the corresponding shear force.

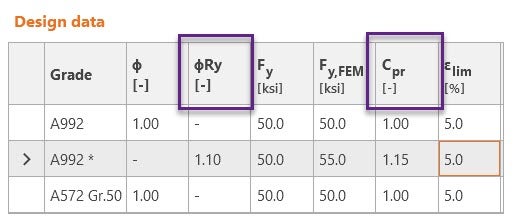

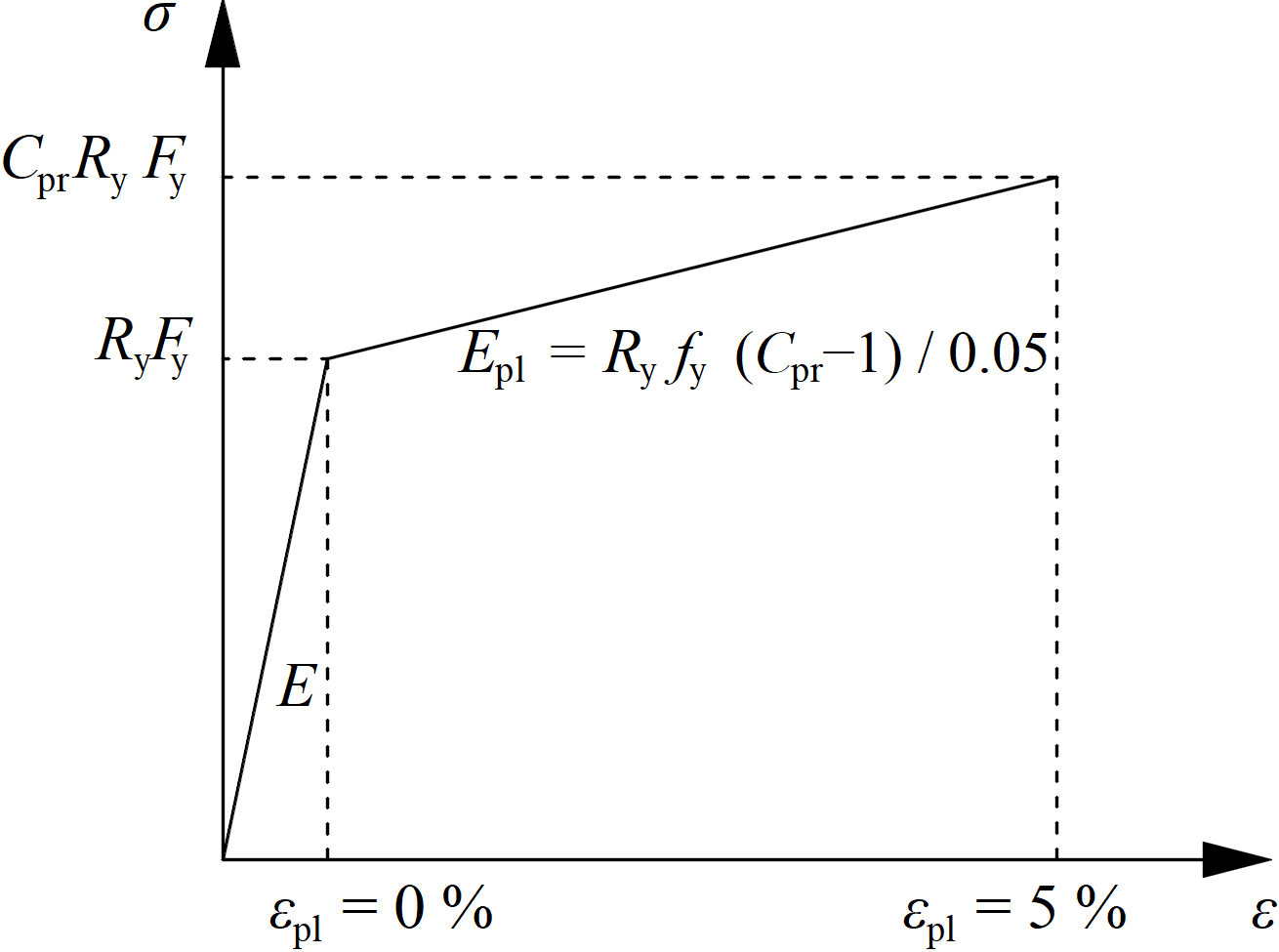

When the analysis is running, the dissipative item material strength is increased by the overstrength factor (Ry) and hardening factor (CPr).

IDEA StatiCa Connection checks the connection for the applied design load, which should create a plastic hinge in the selected dissipative item. The plastic strain in the dissipative item should be around 5%. This can confirm that the magnitude and position of loads were correctly determined.

We are covered in all the non-patented prequalified connections. However, you need to double-check if the prequalification limits were satisfied. This makes the modeling process very tedious as, in some cases, there can be more than 50 detailing checks for each connection.

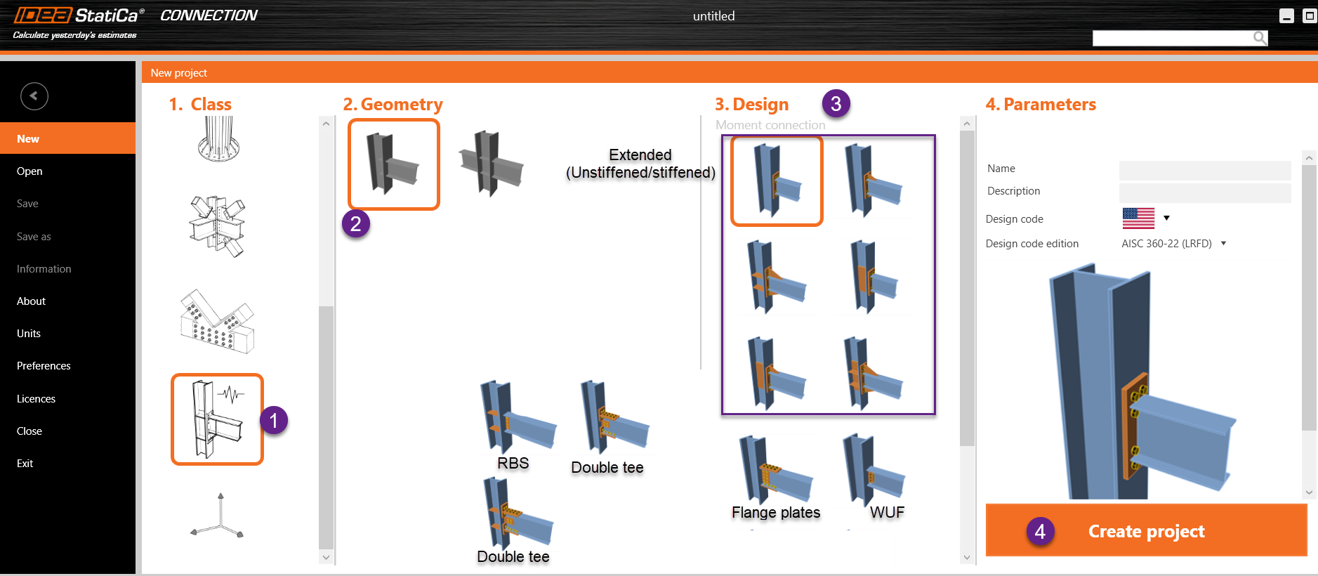

IDEA StatiCa Connection includes the prequalification detailing checks for the following listed connections, and we added connection templates that will help you with a model already constructed.

In the connection menu, you can choose between Special Moment Frame and Intermediate Moment Frame, and the type of connection you will design. This is important and depends on the detailing checks you get at the report:

Detailing checks will show on the model screen while you work on the steel connection so you learn what needs to be changed before running the analysis. Finally, print the checks in the report.

Additional resources

Read our theoretical background for capacity design for more detailed information about the features that will reduce the time spent code-checking prequalified steel connections.

Watch a short introduction video to the prequalified connection design.

If you design these connections and want to reduce iteration time, discover the benefits through our free trial via the link below.