Caso de estudio

Optimizing steel connection production, Rijssen, Netherlands

Steel

Connection

With the installation of the fully automatic assembly and welding machine, Voortman redesigned all standard connections with IDEA StatiCa Connection to maximize production efficiency.

Voortman steel group is one of the leading fabricators in the production of machines for the preparation, processing, and production of steel structures, details, and connections.

Implementation of IDEA StatiCa Connection to their workflows decreases the consumption and handling of the material and the welding costs in comparison to the previously used approach. This went hand in hand with simplifying and speeding up the production process.

Thijs Oerbekke, Registered Structural Engineer / Welding- & Quality Engineer, Voortman Steel Construction

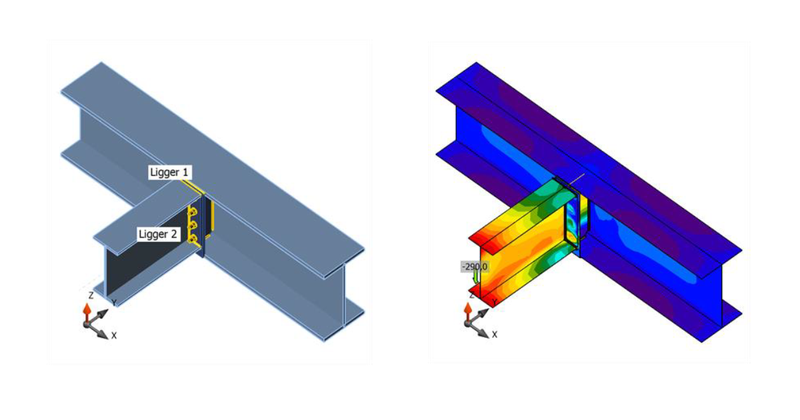

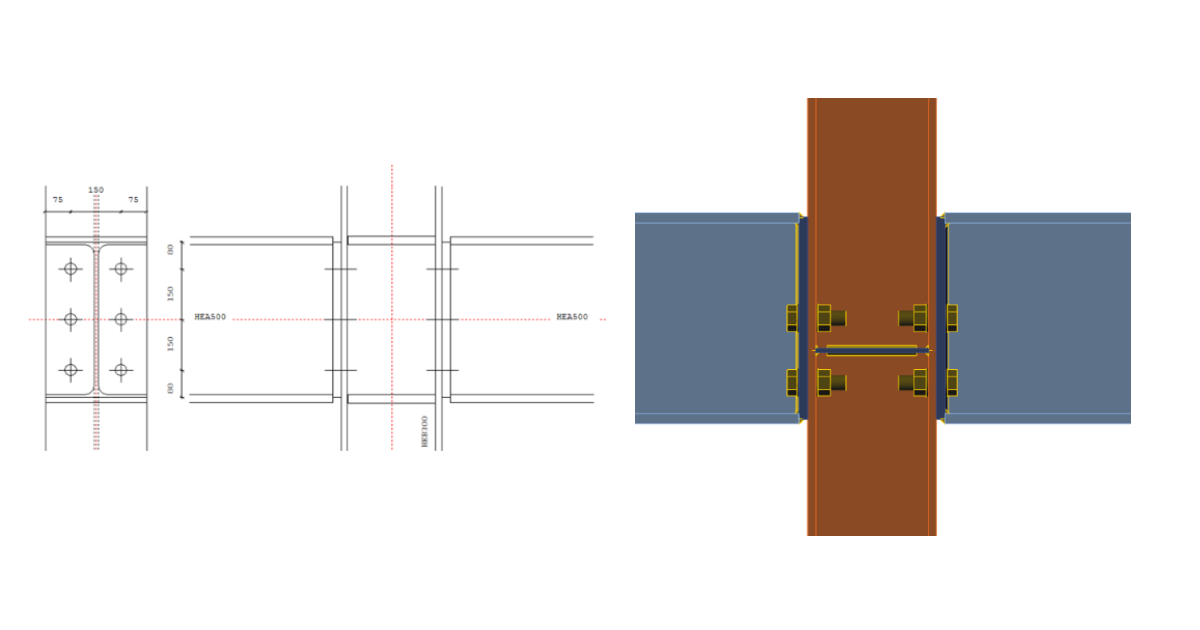

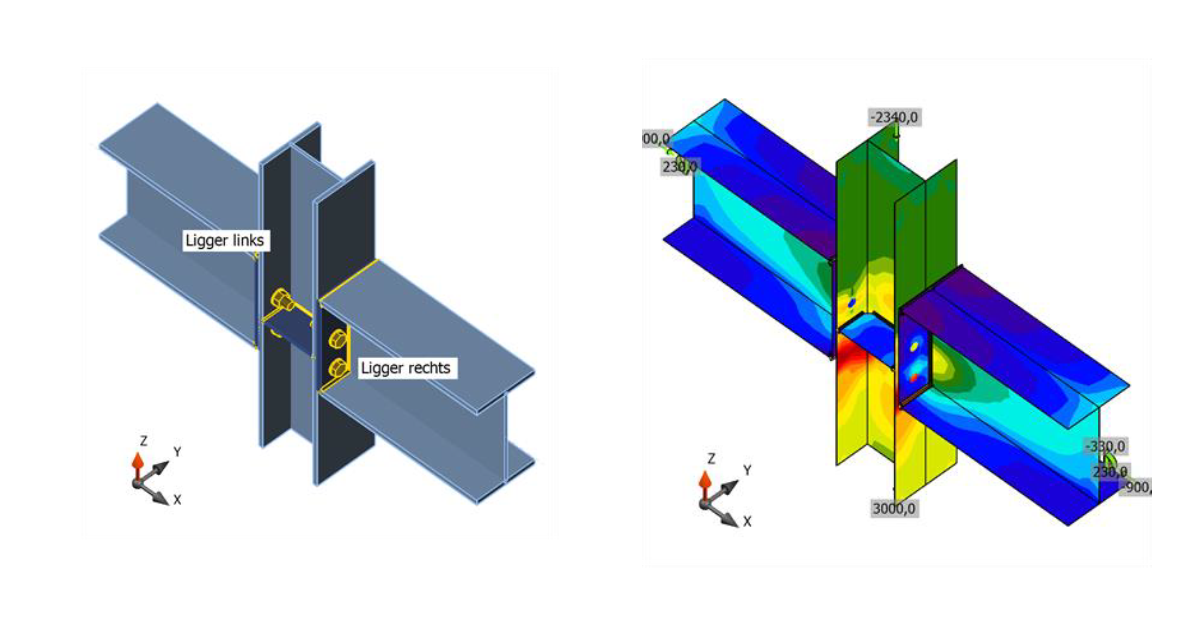

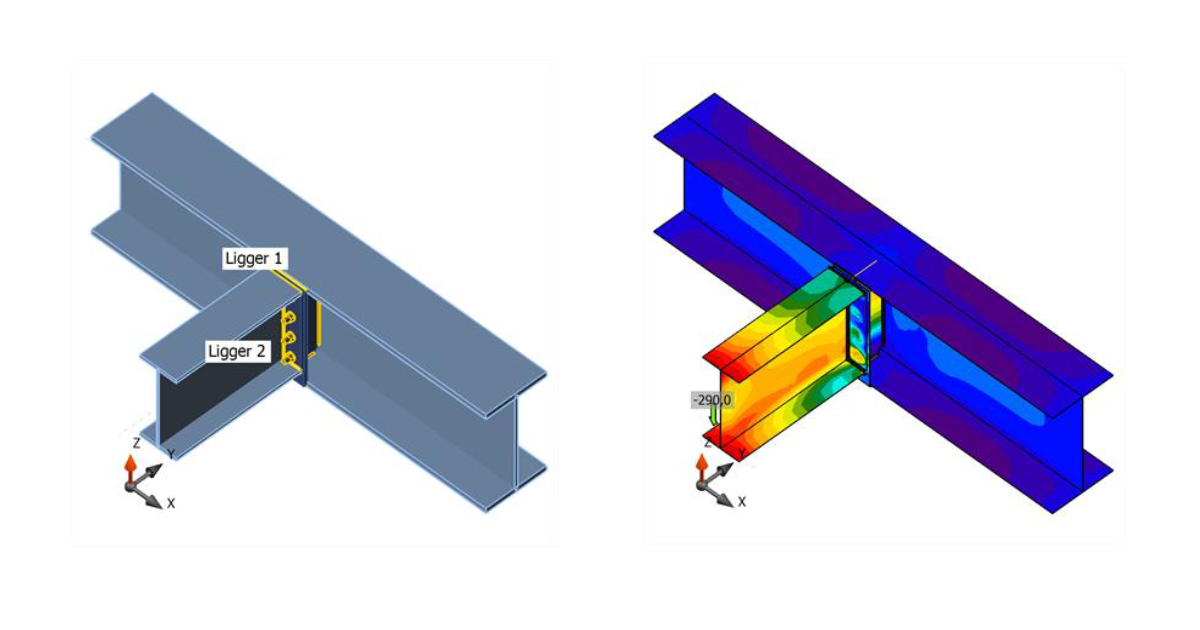

Example of standard connection optimization with IDEA StatiCa Connection

| Standard connection designed by the component method: | Standard connection designed by IDEA StatiCa CBFEM method: |

| End plate: thickness 25 mm weld flanges 13 mm weld webs 8 mm | End plate: thickness 20 mm weld flanges 8 mm weld webs 5 mm |

| 4 x stiffener: thickness 25 mm weld flanges 13 mm weld webs 8 mm | 2 x stiffener: thickness 10 mm weld flanges 5 mm weld webs 5 mm |

| Bolts: 2 x 6 x M36 | Bolts: 2 x 4 x M36 |

Savings:

- End plates 25%

- Stiffeners 60% (not only the material but also fewer parts to be produced, handled and assembled)

- Welds 38% throat thickness, welding volume up to 70% (the welding volume determines the welding cost)

- Bolts 33%

Weld and plate optimization, Mill tolerances, and accessibility are taken into account.