Optimizing steel connection production, Rijssen, Netherlands

Voortman steel group is one of the leading fabricators in the production of machines for the preparation, processing, and production of steel structures, details, and connections.

Implementation of IDEA StatiCa Connection to their workflows decreases the consumption and handling of the material and the welding costs compared to the previously used approach. This went hand in hand with simplifying and speeding up the production process.

Thijs Oerbekke, Registered Structural Engineer / Welding- & Quality Engineer, Voortman Steel Construction

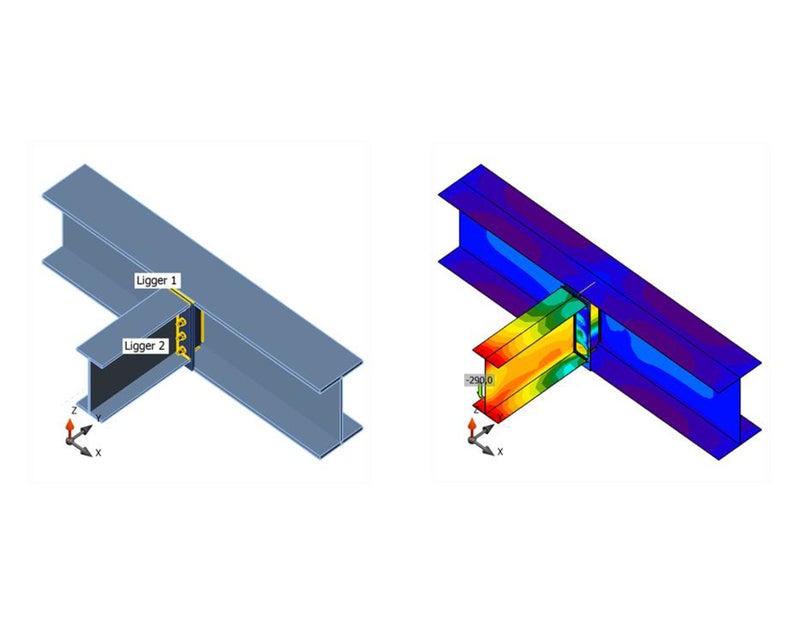

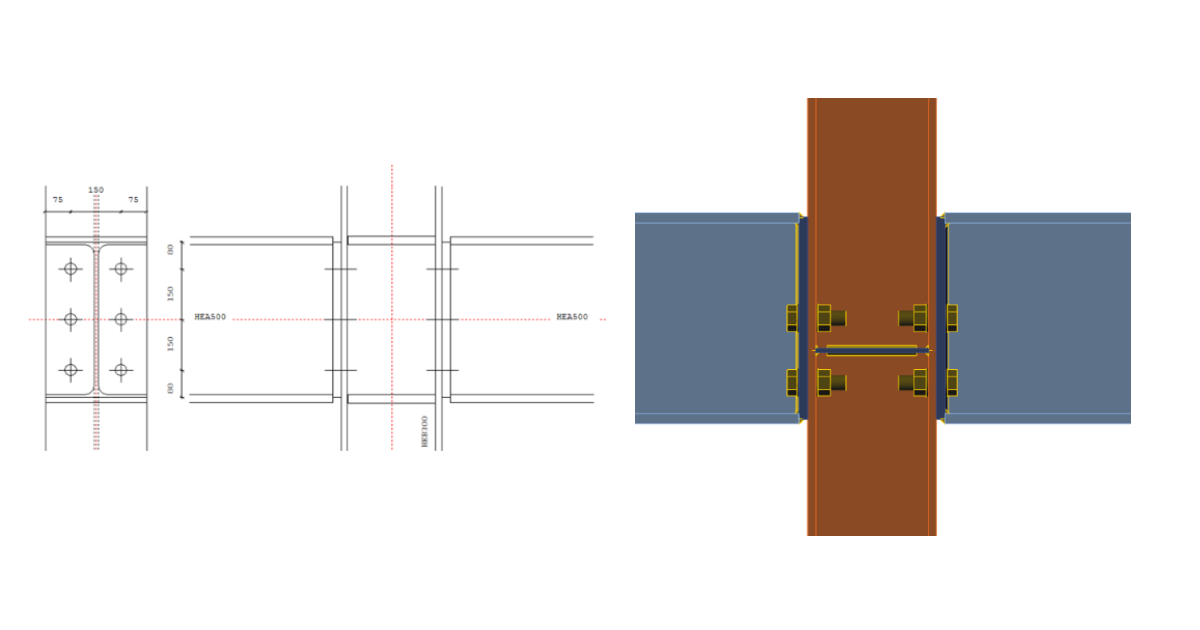

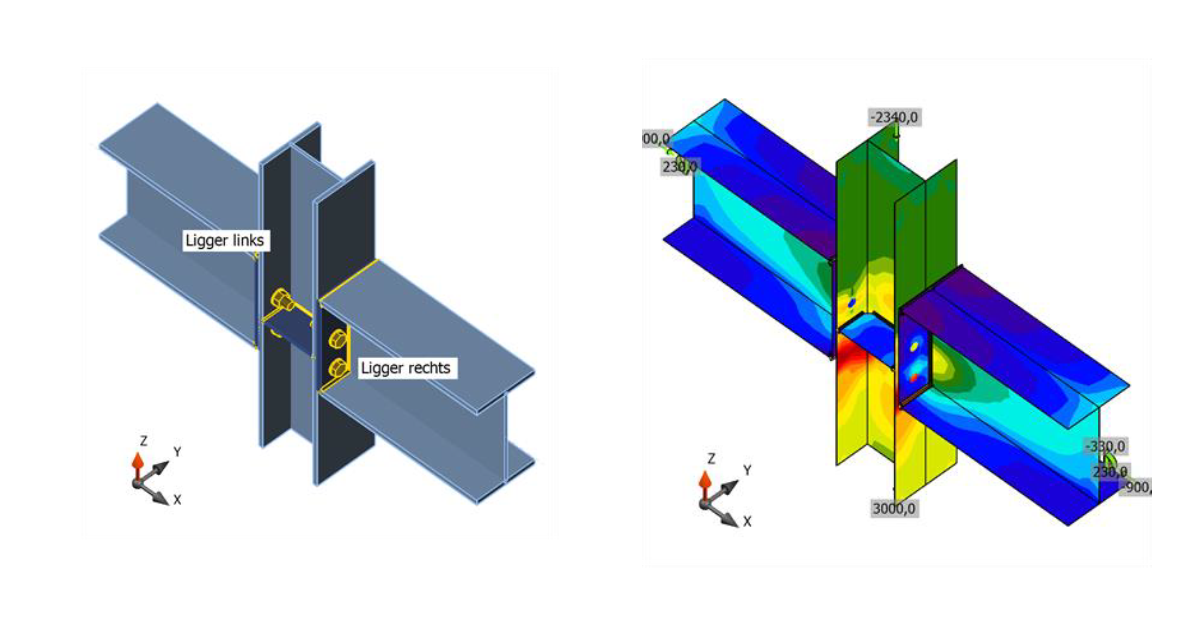

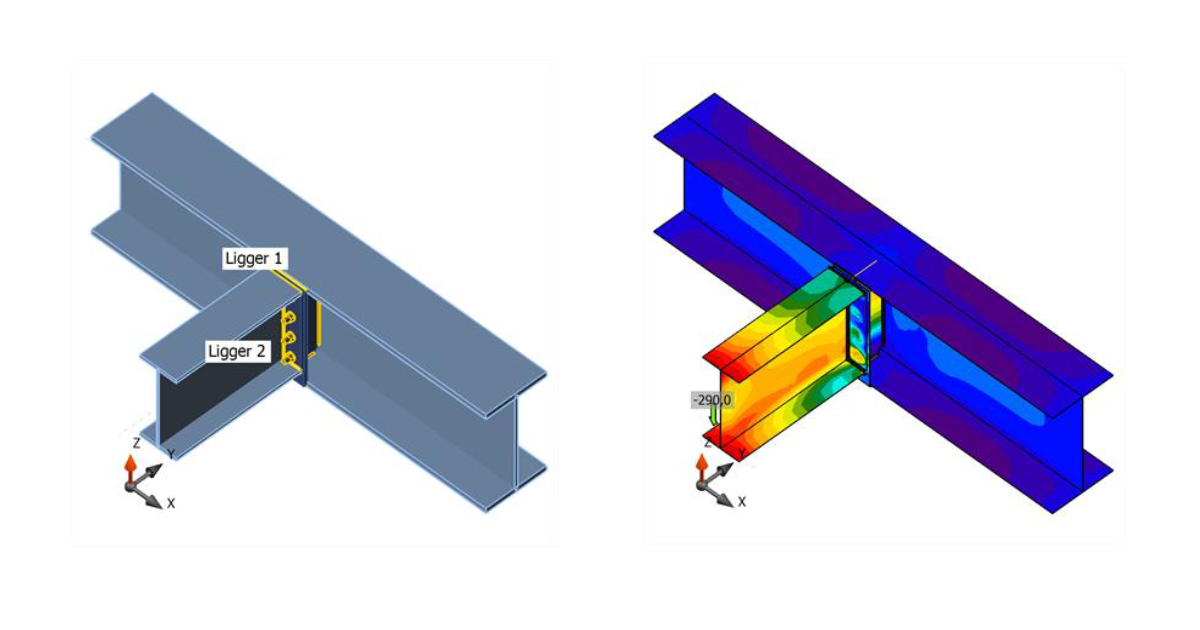

Example of standard connection optimization with IDEA StatiCa Connection

| Standard connection designed by the component method: | Standard connection designed by IDEA StatiCa CBFEM method: |

| End plate: thickness 25 mm weld flanges 13 mm weld webs 8 mm | End plate: thickness 20 mm weld flanges 8 mm weld webs 5 mm |

| 4 x stiffener: thickness 25 mm weld flanges 13 mm weld webs 8 mm | 2 x stiffener: thickness 10 mm weld flanges 5 mm weld webs 5 mm |

| Bolts: 2 x 6 x M36 | Bolts: 2 x 4 x M36 |

Savings:

- End plates 25%

- Stiffeners 60% (not only the material but also fewer parts to be produced, handled, and assembled)

- Welds 38% throat thickness, welding volume up to 70% (the welding volume determines the welding cost)

- Bolts 33%

Weld and plate optimization, Mill tolerances, and accessibility are considered.

Conclusion

The specific design of the connections influences the price of the entire construction. It depends not only on the amount of steel used but also on the number of welds, the number and diameter of bolts, and the overall complexity of the connection. Thanks to IDEA StatiCa Connection, you can optimize the cost of making the connection, considering all the operations that occur during execution.

Save with IDEA StatiCa Connection!