Steel canopy structure of Opportunity Pavilion

About the project

The Opportunity Pavilion was designed by AGi Architects for Expo 2020 in Dubai. The structure was conceived as a large plaza, providing continuity to the Opportunity District in which it is situated. The goal of the Opportunity Pavilion was to create an engaging, inspiring environment that underscores Expo 2020's commitment to promoting better access to essential resources and achieving the UN’s Sustainable Development Goals.

Eversendai's engineers played a key role in the project, focusing specifically on the canopy steelwork design. The canopy floating 32 meters above the ground represents clouds symbolizing dreams that people aspire to achieve. The plaza is placed on two levels, bridging the terrain's slope. The canopy is composed of six steel overlapping layers, transforming with respect to the time of day and light.

Engineering Challenges

The Opportunity Pavilion's design was a giant challenge by itself due to its architectural requirements. Multiple truss systems intertwined across various layers, forming an intricate 3D structure with extensive cantilevers that span over 40 meters. Everything is supported by a few columns.

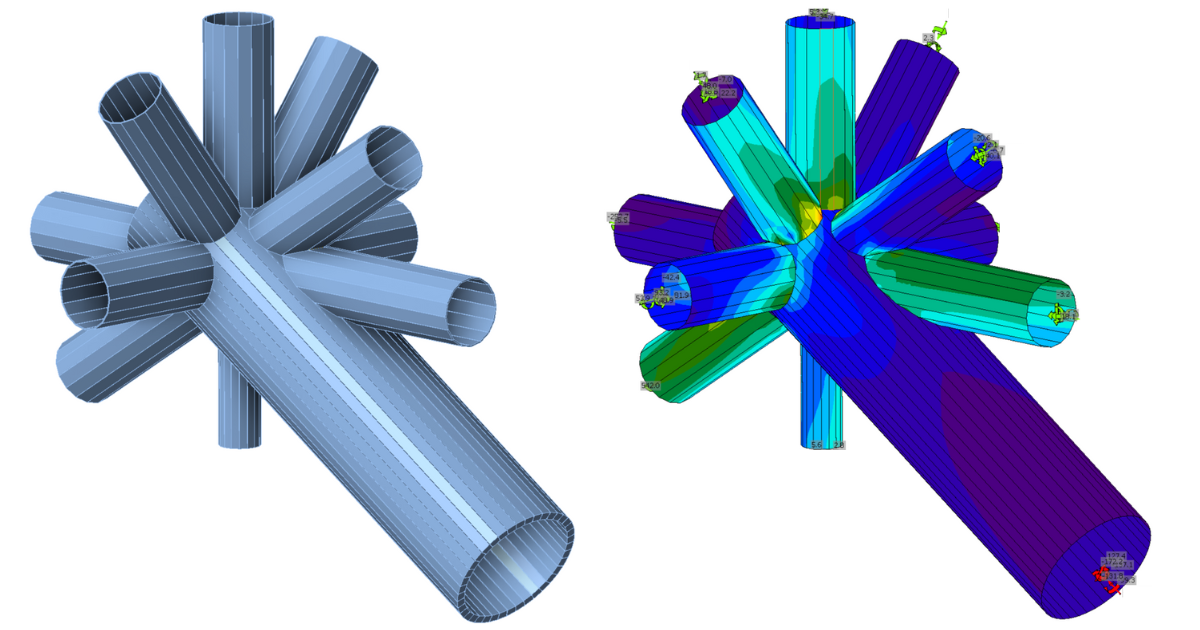

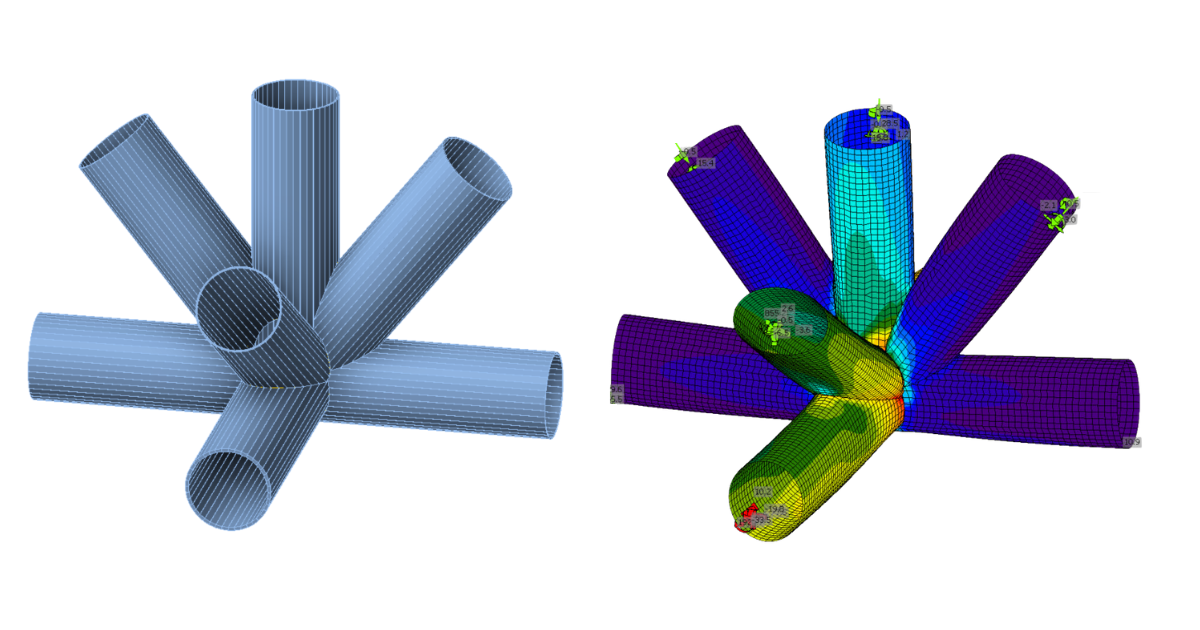

The project required Opportunity Pavilion to be completed within four months, including detailed design, procurement, interface coordination, fabrication, and construction. Only one month was dedicated to managing the complex structural design, including verification of more than 1,600 unique connection types. All joints are really complex, with around 10 members meeting in various angles at one point. Joints comprised of 18 members were no exception. Each node demanded code-checking and optimization to ensure material efficiency without compromising structural integrity. As the structure was not permanent and was disassembled, the design emphasized the use of very thin profiles to minimize material consumption.

\[ \textsf{\textit{\footnotesize{Example of a complex connection comprising of 17 members}}}\]

Solutions and results

The initial draft of the truss systems was conducted in Tekla, with all members designed as circular hollow section (CHS) members. All joints were engineered as welded to ensure a pure and united structure to avoid any visible connections. Due to minimum thickness, a code-check of stresses on the walls was essential for verification. Engineers from Eversendai decided to use the application IDEA StatiCa Connection to understand the behavior of the joints, optimize them, and verify many combinations simultaneously.

Moreover, the software helped them to perform geometrically nonlinear analysis (GMNA) and analyze local deformations of hollow cross-section members knowing that extremally slender walls with point loads can be negatively influenced by local deformations which impact the overall stability of members.

During the design, engineers had to find a solution that passes through all relevant checks and consumes a minimum of steel, but also a solution that is quick and easy to fabricate. Usually, for such connections, engineers tend to design inside stiffeners, ring stiffeners, or gusset plates, which was not possible in this case. For this time-sensitive project, they had to cut down these operations to a minimum to help the fabrication team to deliver the structure on time.

The structural engineers were in constant contact with the fabrication team to ensure their design was optimized also for rapid assembly. To expedite the construction process, they deviated from the typical practice of transporting 3-meter sections. Instead, they preassembled larger up to 5.5-meter parts in the construction hall, which were then delivered to the site, significantly reducing on-site assembly time and downsizing the overall project timeline.

United Arab Emirates

About Eversendai

Eversendai Engineering Offices in India, UAE, and Qatar provide comprehensive technical and end-to-end design services, from conceptual design to detailed design including engineering for various types of structures by highly qualified and experienced design engineers and detailers. Thanks to direct contact with the erection steel engineering department, the collaboration can minimize misunderstandings and discrepancies. Structural engineers can incorporate real-world constraints and feedback from the erection team, leading to designs that are not only theoretically sound but also feasible and safe during the erection process. This leads to projects that are more practical to implement, avoiding delays and costly changes. Fabrication of the Opportunity Pavilion in four months is a great example of their 40 years of experience.

Conclusion

The Opportunity Pavilion stands as an impressive example of modern engineering, balancing architectural ambition with practical challenges. Despite tight timelines, the use of advanced tools like IDEA StatiCa enabled efficient designing and code-checking of complex nodes. Cooperation between structural engineers and the prefabrication team enabled them to find a way to deliver the project on time. The project's completion showcased not only the technical capabilities of Eversendai Engineering but also their ability to deliver under demanding conditions.

Prueba IDEA StatiCa gratis