Connection optimization at the Dubai Expo COEX

About the project

Spanning approximately 240 meters in length and 120 meters in width, the COEX Centre consists of multiple structural elements, including a vast exhibition hall, arrival plaza, concourse, and a steel canopy. The structural system is predominantly steel, designed to achieve a balance between lightweight efficiency and high load-bearing capacity. A major focus of the project was sustainability, as several steel components had been fabricated under an earlier contract and were repurposed to minimize material waste. This required a careful assessment of the pre-existing fabricated elements and their integration into the new design, ensuring compatibility with modern engineering requirements.

Given the complexity and scale of the project, the structural design had to accommodate various constraints, including connection design and optimization. The challenge was not only to design structurally sound connections but also to ensure that the connections were straightforward to manufacture and assemble, supporting an accelerated construction timeline.

Engineering Challenges

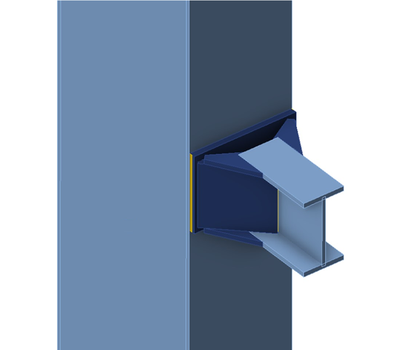

The COEX project presented multiple engineering challenges, particularly in the design of the steel connections. The structural framework had to support significant axial forces while maintaining efficiency in material usage. One of the most demanding aspects was the design of the main truss connections to the supporting columns. These connections needed to achieve full member capacity while remaining pinned, preventing the transfer of bending moments. This required precise detailing to ensure that axial forces were properly managed without introducing unwanted stiffness into the structure.

Another challenge was the integration of previously fabricated steel members into the new design. Part of Tony Gee and Partners' scope was primarily focused on assessing the connections of these pre-existing elements to ensure their structural adequacy for the new design intent. As these components were originally manufactured for a different purpose, they required a thorough evaluation, and if their capacity was found inadequate to carry the new design loads, the connections had to be redesigned in a cost-effective manner, retaining as much of the existing connection elements as possible. The variability in these elements added complexity to the task, requiring advanced analysis methods to confirm the overall structural performance.

The roof bracing connections and arrival plaza truss-end connections also required careful attention. These elements had to accommodate dynamic loading conditions while remaining efficient to fabricate. The design had to strike a balance between strength, durability, and ease of assembly, all while aligning with the project’s architectural vision.

Solutions and Results

To address the challenges of designing and optimizing the steel connections, Tony Gee and Partners employed IDEA StatiCa Connection. Its ability to perform detailed stress evaluations and model complex interactions between steel components allowed the engineering team to refine connection designs with a high degree of accuracy. By simulating real-world loading conditions, they could identify potential weaknesses and optimize the geometry for maximum efficiency.

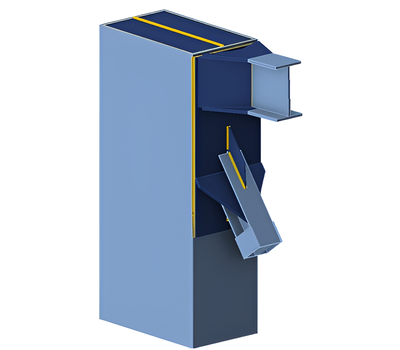

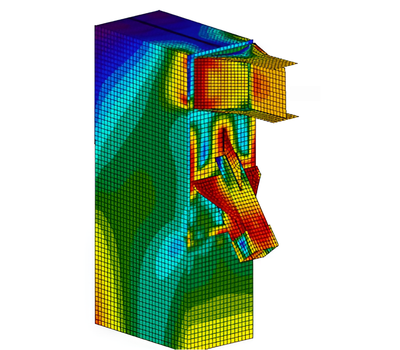

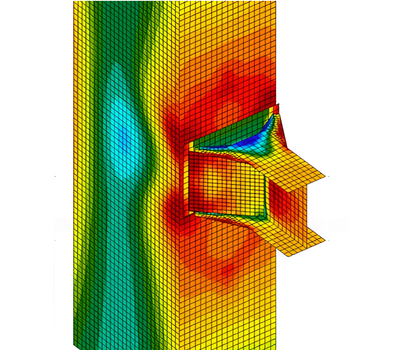

The main truss-to-column connections were among the most critical elements analyzed using the Connection app. These connections were modeled in 3D to assess their ability to sustain axial forces while maintaining the required pinned behavior. The software enabled the team to run geometrically linear analysis with material and contact nonlinearities, providing a clear understanding of stress distribution and deformation. Additionally, Eigenvalue analysis was performed to evaluate potential buckling risks, ensuring that the connections met all performance criteria.

For the previously fabricated steel members, Connection was used to assess different connection configurations, ensuring they could be effectively integrated into the new design. The analysis helped determine whether modifications were needed and how the repurposed elements could be optimized to align with the project’s structural requirements. This approach minimized material waste while maintaining structural reliability.

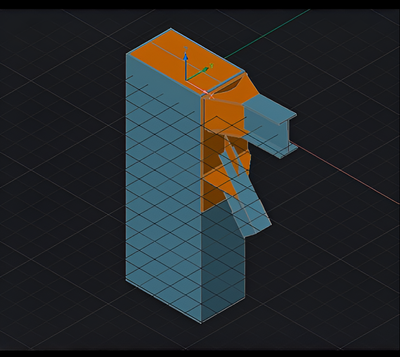

The design process was further simplified through IDEA StatiCa’s integration with CAD software. The ability to export 3D models and generate 2D sketches facilitated clear communication between engineering and drafting teams, reducing the risk of errors and improving construction efficiency. This integration ensured that the final connection designs were both practical to manufacture and easy to assemble on-site.

The use of advanced analysis tools ultimately enabled the successful execution of the COEX Centre’s steel framework. The optimized connection designs not only met structural performance requirements but also contributed to a visually cohesive architectural aesthetic. The powerful integration of engineering and design ensured that the COEX Centre remained both a functional and iconic structure, demonstrating excellence in modern steel construction.

Conclusion

Through a combination of engineering expertise and cutting-edge software tools, Tony Gee and Partners successfully delivered a steel framework that met the highest standards of safety, efficiency, and architectural refinement. The COEX Centre stands as a testament to the power of precision engineering and the role of innovative digital solutions in modern structural design..

About Tony Gee and Partners

For over 50 years, Tony Gee has been delivering innovative, construction-led engineering solutions, specializing in permanent and temporary works design. Their expertise lies in integrating design with construction, working closely with clients, contractors, and designers to develop efficient, buildable, and cost-effective solutions. With a strong focus on modern construction techniques and material efficiency, they provide independent design checks, complex solution verifications, and construction methodology assessments, ensuring robust engineering integrity.

Operating across the UK and international markets, they understand the logistical and technical challenges of major infrastructure projects. Their highly skilled professionals, supported by advanced design and BIM software, drive quality, innovation, and timely project delivery. With in-house capabilities in civil, geotechnical, and permanent way design, complemented by a trusted supply chain of specialists, they offer comprehensive engineering services that adapt to evolving client needs, ensuring practical and economical solutions.

Essayez IDEA StatiCa gratuitement