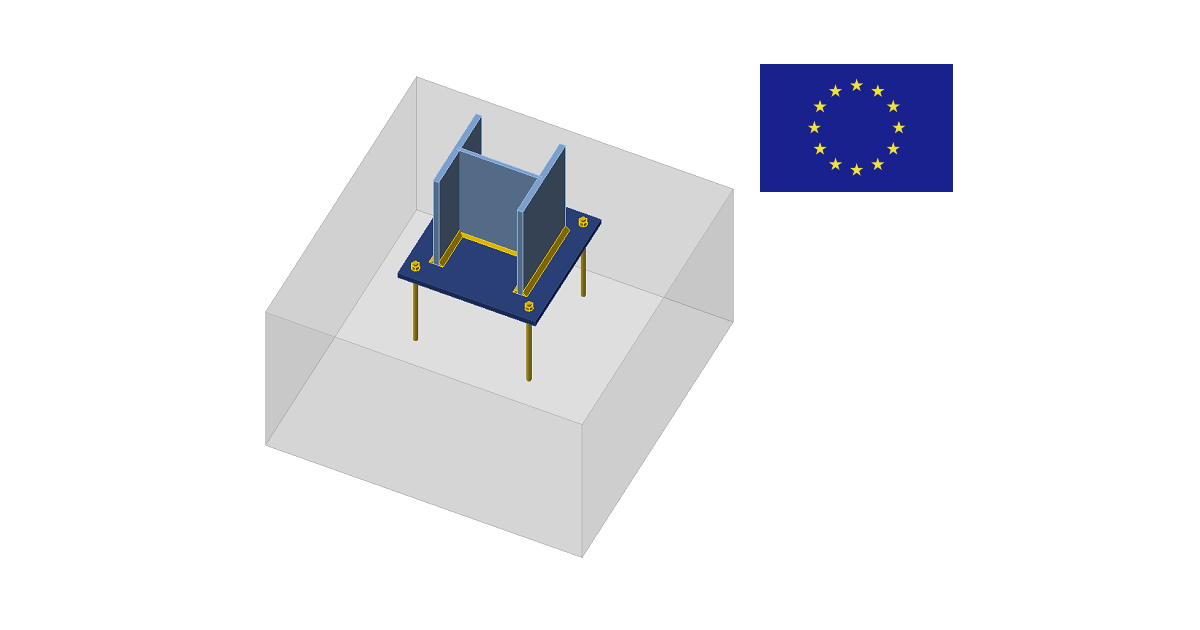

Code-check of anchors (EN)

Four anchor bolt types are available:

- Straight (assumed post-installed)

- Washer plate - Circular (assumed cast-in)

- Washer plate - Rectangle (assumed cast-in)

- Hook (assumed cast-in)

The steel resistances are determined according to EN 1993-1-8 and EN 1992-4 for cast-in anchors and post-installed fasteners, respectively.

The concrete resistances are determined according to EN 1992-4.

In case of post-installed (straight) fasteners, pull-out failure, combined pull-out and concrete failure of bonded anchors, and concrete splitting failure are not checked due to missing information available only for the particular anchor and glue type from the anchor manufacturer.

In the Project settings, settings are available to activate/deactivate concrete cone breakout checks in tension and shear. If the concrete cone breakout check is not activated, it is assumed that the dedicated reinforcement is designed to resist the force. The magnitude of the force is provided in formulas. User may use link to Detail application to perform the checks of reinforced concrete.

Furthermore, the concrete can be set as cracked or uncracked. Uncracked concrete should be in permanent compression that prevents shrinkage cracks. The resistances of uncracked concrete are higher.

Tensile steel resistance (EN 1993-1-8, Table 3.4)

Cast-in anchors are checked according to steel design code.

\[ F_{t,Rd} = \frac{c \cdot k_2 \cdot f_{ub} \cdot A_s}{\gamma_{M2}} \]

where:

- c – decrease in tensile resistance of bolts with cut thread according to EN 1993-1-8 – Cl. 3.6.1. (3) editable in Project Settings

- k2 = 0.9 – factor for non-countersunk anchors

- fub – anchor bolt ultimate tensile strength

- As – anchor bolt tensile stress area

- \(\gamma_{M2}=1.25\) – partial safety factor for bolts (EN 1993-1-8, Table 2.1) editable in Project Settings

Tensile steel resistance (EN 1992-4, Cl. 7.2.1.3)

Post-installed fasteners are checked according to concrete design code

\[ N_{Rd,s} = \frac{N_{Rk,s}}{\gamma_{Ms}} \]

where:

- NRk,s = c ∙ As ∙ fuk – characteristic resistance of a fastener in case of steel failure

- c – decrease in tensile resistance of bolts with cut thread according to EN 1993-1-8 – Cl. 3.6.1. (3) editable in Code setup

- As – anchor bolt tensile stress area

- fuk – anchor bolt characteristic ultimate tensile strength

- \(\gamma_{Ms}=1.2 \cdot \frac{f_{uk}}{f_{yk}} \ge 1.4\) – partial safety factor for steel failure in tension (EN 1992-4, Table 4.1)

- fyk – anchor bolt characteristic yield strength

Concrete cone failure resistance of anchor or group of anchors (EN 1992-4, Cl. 7.2.1.4):

\[ N_{Rd,c} = \frac{N_{Rk,c}}{\gamma_{Mc}} \]

where:

- \(N_{Rk,c}=N_{Rk,c}^0 \cdot \frac{A_{c,N}}{A_{c,N}^0} \cdot \psi_{s,N} \cdot \psi_{re,N} \cdot \psi_{ec,N} \cdot \psi_{M,N}\) – characteristic resistance of a fastener, a group of fasteners and the tensioned fasteners of a group of fasteners in case of concrete cone failure

- \(N_{Rk,c}^0 = k_1 \sqrt{f_{ck}} h_{ef}^{1.5}\) – characteristic resistance of a single fastener placed in concrete and not influenced by adjacent fasteners or edges of the concrete member

- k1 – factor taking into account concrete condition and anchor type; for cast-in headed anchors (with washer plates) k1 = 8.9 for cracked concrete and k1 = 12.7 for non-cracked concrete; for post-installed fasteners (straight anchors) k1 = 7.7 for cracked concrete and k1 = 11.0 for non-cracked concrete

- fck – characteristic concrete compressive cylinder strength

- hef – embedment depth of the anchor in concrete; for three or more close edges, EN 1992-4, Cl. 7.2.1.4 (8) applies and effective \(h'_{ef} = \max \left \{ \frac{c_{max}}{c_{cr,N}} \cdot h_{ef}, \, \frac{s_{max}}{s_{cr,N}} \cdot h_{ef} \right \}\) is used instead in formulas for NRk,c0, ccr,N, scr,N, Ac,N, Ac,N0, ψs,N, and ψec,N

- Ac,N – actual projected area, limited by overlapping concrete cones of adjacent fasteners as well as by edges of the concrete member

- Ac,N0 = scr,N2 – reference projected area, i.e. area of concrete of an individual anchor with large spacing and edge distance at the concrete surface

- \(\psi_{s,N}=0.7+0.3 \cdot \frac{c}{c_{cr,N}} \le 1\) – factor taking into account disturbance of the distribution of stresses in the concrete due to the proximity of an edge of the concrete member

- c – smallest edge distance

- ccr,N = 1.5 ∙ hef – characteristic edge distance for ensuring the transmission of the characteristic resistance of an anchor in case of concrete break-out under tension loading

- \(\psi_{re,N}=0.5+\frac{h_{ef}}{200} \le 1\) – shell spalling factor

- \(\psi_{ec,N}=\frac{1}{1+2 \cdot (e_N / s_{cr,N})} \le 1\) – factor taking into account group effect when different tension loads are acting on the individual fasteners of a group; ψec,N is determined separately for each direction and the product of both factors is used

- eN – eccentricity of resultant tension force of tensioned fasteners in respect to the center of gravity of the tensioned fasteners

- scr,N = 2 ∙ ccr,N – characteristic spacing of anchors to ensure the characteristic resistance of the anchors in case of concrete cone failure under tension load

- \(\psi_{M,N} = 2- \frac{z}{1.5 \cdot h_{ef}} \ge 1\) – factor taking into account effect of a compression force between fixture and concrete in cases of bending moments with or without axial force; this parameter is equal to 1 if c < 1.5 hef or the ratio of the compressive force (including the compression due to bending) to the sum of tensile forces in anchors is smaller than 0.8 or z / hef ≥ 1.5

- z – internal lever arm of a fastening

- γMc = γc ∙ γinst – partial safety factor (EN 1992-4, Table 4.1)

- γc – partial safety factor for concrete (editable in Code setup)

- γinst – partial safety factor taking account of the installation safety of an anchor system (editable in Code setup)

The concrete breakout cone area for a group of anchors loaded by tension that creates a common concrete cone, Ac,N, is shown by the red dashed line.

Pull-out resistance (EN 1992-4, Cl. 7.2.1.5)

Pull-out resistance is checked for cast-in anchors with washer plates according to EN 1992-4, Cl. 7.2.1.5:

\[ N_{Rd,p}=\frac{N_{Rk,p}}{\gamma_{Mc}} \]

where:

- NRk,p = k2 ∙ Ah ∙ fck – characteristic resistance in case of pull-out failure

- k2 – coefficient dependent on concrete condition, k2 = 7.5 for cracked concrete, k2 = 10.5 for non-cracked concrete

- Ah – bearing area of head of anchor; for circular washer plate \(A_h = \frac{\pi}{4} \left ( d_h^2 - d^2 \right )\), for rectangular washer plate \(A_h = a_{wp}^2 - \frac{\pi}{4} d^2\)

- dh ≤ 6 th + d – diameter of the head of the fastener

- th – thickness of the head of the headed fastener

- d – diameter of the shank of the fastener

- fck – characteristic concrete compressive cylinder strength

- γMc = γc ∙ γinst – partial safety factor (EN 1992-4, Table 4.1)

- γc – partial safety factor for concrete (editable in Code setup)

- γinst – partial safety factor taking account of the installation safety of an anchor system (editable in Code setup)

Pull-out resistance (EN 1992-1-1, Cl. 8.4.4)

Pull-out resistance is checked for cast-in anchors with hook according to EN 1992-1-1, Cl. 8.4.4. Plain rods are assumed that require double anchorage length than ribbed reinforcement (Table 3.26 in BS 8110-1).

\[N_{Rd,p}=A_a \cdot f_{ya} \cdot \frac{l_b}{l_{bd}}\]

where:

- Aa – tensile stress area of an anchor

- fya – anchor yield strength

- lb – anchor length embedded in concrete

- \(l_{bd} = \alpha_1 \cdot \alpha_2 \cdot \alpha_3 \cdot \alpha_4 \cdot \alpha_5 \cdot l_{b,rqd}\) – design anchorage length

- \(\alpha_1\) – factor for the effect of the shape of the bars assuming adequate cover

- \(\alpha_1 = 0.7\) for \(c_d > 3 \phi\)

- \(\alpha_1 = 1.0\) for \(c_d \le 3 \phi\)

- \(c_d = \min \{a/2, c_1\}\) – adequate cover

- a – clear distance between anchors

- c1 – clear distance to concrete block edge

- \(\phi\) – anchor diameter

- \(\alpha_2 = 1.0 - 0.15 \frac{c_d - \phi}{\phi}\) – factor for the effect of concrete minimum cover; \(0.7 \le \alpha_2 \le 1.0\)

- \(\alpha_3 = 1.0\) – factor for the effect of confinement by transverse reinforcement

- \(\alpha_4 = 1.0 \) – factor for the influence of one or more welded transverse bars along the design anchorage length

- \(\alpha_5=1.0\) – factor for the effect of the pressure transverse to the plane of splitting along the design anchorage length

- \(l_{b,rqd} = \frac{\phi}{4} \frac{f_{ya}}{f_{bd}}\) – required anchorage length

- \(f_{bd} = \frac{2.25 \cdot \eta_1 \cdot \eta_2 f_{ctd}}{2}\) – design value of the ultimate bond stress (assumed half that of ribbed reinforcement)

- \(\eta_1=1.0\) – coefficient related to the quality of the bond condition and the position of the bar during concreting; good conditions are assumed, which may be dangerous for the rare case of horizontal anchors placed at the top of the concrete

- \(\eta_2=\min \{1.0, \frac{132-\phi}{100}\) – coefficient related to the bar diameter

- \(f_{ctd}=\frac{\alpha_{ct} \cdot f_{ctk,0.05}}{\gamma_c}\) – design value of concrete tensile strength

- \(\alpha_{ct}=1.0\) – coefficient taking account of long term effects on the tensile strength and of unfavourable effects

- \(f_{ctk,0.05}\) – characteristic axial tensile strength of concrete (5% quantile)

- \(\gamma_c\) – safety factor for concrete editable in Project Settings

Several detailing rules are added:

- Anchor yield strength must not be higher than 300 MPa (EN 1993-1-8 – 6.2.6.12 (5))

- Minimum anchorage length \(l_{b,min}\) must be kept (EN 1992-1-1 – Equation (8.6)):

\[ l_b \ge l_{b,min} = \max \{ 0.3 \cdot l_{b,rqd}, 10\cdot \phi , 100 \}\]

- Anchorage length should be sufficient for the steel tensile failure mode to govern to facilitate plastic design

The pullout resistance of other types of anchors is not checked and must be guaranteed by the manufacturer.

Concrete blowout resistance (EN 1992-4, Cl. 7.2.1.8)

Blow-out failure is checked for cast-in headed anchors (Anchor type – washer) with edge distance c ≤ 0.5 hef according to EN 1992-4, Cl. 7.2.1.8. Anchors are treated as a group if their spacing near the edge is s ≤ 4 c1. Undercut anchors can be checked the same way but the value of Ah is unknown in the software. The blow-out failure of undercut anchors can be determined by selecting a washer plate with the corresponding dimension.

\[N_{Rd,cb} = \frac{N_{Rk,cb}}{\gamma_{Mc}}\]

where:

- \(N_{Rk,cb} = N_{Rk,cb}^0 \cdot \frac{A_{c,Nb}}{A_{c,Nb}^0} \cdot \psi_{s,Nb} \cdot \psi_{g,Nb} \cdot \psi_{ec,Nb}\) – characteristic resistance in case of concrete blow-out failure

- \(N_{Rk,cb}^0 = k_5 \cdot c_1 \cdot \sqrt{A_h} \cdot \sqrt{f_{ck}}\) – characteristic resistance of a single fastener, not influenced by adjacent fasteners or further edges

- Ac,Nb – actual projected area, limited by overlapping concrete break-out bodies of adjacent fasteners as well as by proximity of edges of the concrete member or the member thickness

- Ac,Nb0 = (4 c1)2 – reference projected area of a single fastener with an edge distance equal to c1

- \(\psi_{s,Nb} = 0.7+0.3 \frac{c_2}{2 c_1} \le 1\) – factor taking into account the disturbance of the distribution of stresses in the concrete due to the proximity of a corner of the concrete member

- \( \psi_{g,Nb} = \sqrt{n} + (1-\sqrt{n}) \frac{s_2}{4c_1} \ge 1 \) – factor taking into account group effect

- \(\psi_{ec,Nb} = \frac{1}{1+2 e_N / s_{cr,Nb}} \le 1\) – factor taking into account group effect, when different loads are acting on the individual fasteners of a group

- k5 – parameter related to the state of the concrete; for cracked concrete k5 = 8.7, for uncracked concrete k5 = 12.2

- c1 – edge distance of fastener in direction 1 towards the closest edge

- c2 – edge distance of fastener perpendicular to direction 1 that is the smallest edge distance in a narrow member with multiple edge distances

- Ah – area of the load-bearing head of the fastener; for circular washer plate \(A_h = \frac{\pi}{4} \left ( d_h^2 - d^2 \right )\), for rectangular washer plate \(A_h = a_{wp}^2 - \frac{\pi}{4} d^2\)

- d – anchor nominal diameter

- dh – circular washer plate diameter

- awp – side size of squared washer plate

- fck – characteristic compressive cylinder strength of concrete

- n – number of fasteners in a row parallel to the edge of the concrete member

- s2 – spacing of fasteners in a group perpendicular to direction 1

- scr,Nb = 4 c1 – spacing that is required for a fastener to develop its characteristic tensile strength against blow-out failure

Anchor shear steel resistance (EN 1993-1-8 – Cl. 6.2.2)

Anchor shear steel resistance of cast-in anchors is determined according to EN 1993-1-8 – 6.2.2 (7) regardless of direct or mortar joint stand-off. The addition of friction is problematic in practice and is not assumed. The background for Eurocode calculation is the Stevin Laboratory model presented in this paper. Holes should be standard, not oversized and the grout strength and thickness should be according to Cl. 6.2.5 (7).

\[F_{vb,Rd} = \min \{F_{1vb,Rd}, F_{2vb,Rd} \} \]

where:

- \(F_{1vb,Rd} = \frac{\alpha_v \cdot f_{ub} \cdot A}{\gamma_{M2}}\) – anchor shear resistance from Table 3.4

- αv = 0.6 for grades 4.6, 5.6, 8.8 and 0.5 for grades 4.8, 5.8, 6.8, 10.9

- fub – ultimate tensile strength of the bolt

- A – tensile stress area of the bolt

- A = A for shear plane excluded from threads; A is gross cross-section area of the anchor

- A = As for shear plane intercepted by threads; As is tensile stress area of the bolt

- γM2 – safety factor (EN 1993-1-8 – Table 2.1; editable in Project Settings)

- \(F_{2vb,Rd} = \frac{\alpha_b \cdot f_{ub} \cdot A_s}{\gamma_{M2}}\) – anchor shear resistance from Equation (6.2)

- \(\alpha_b = 0.44 - 0.0003 f_{yb}\) – coefficient depending on the yield strength the anchor bolt

- fyb – anchor yield strength; 235 MPa \(\le f_{yb} \le\) 640 MPa

- fub – anchor tensile strength

- As – tensile stress area

Anchor shear steel resistance (EN 1992-4 – Cl. 7.2.2.3)

Anchor shear steel resistance of post-installed fasteners is checked according to EN 1992-4 – Cl. 7.2.2.3. Friction is not taken into account. Shear with and without lever arm is recognized in dependence on base plate manufacturing operation settings.

\[V_{Rd,s} = \frac{V_{Rk,s}}{\gamma_{Ms}}\]

For stand-off: direct, the shear without lever arm is assumed (EN 1992-4 – Cl. 7.2.2.3.1):

VRk,s = k6 ∙ As ∙ fuk – characteristic resistance of a single fastener in case of steel failure; or fasteners with a ratio hef / dnom < 5 and a concrete compressive strength class < C20/25 the characteristic resistance VRk,s should be multiplied by a factor of 0.8.

For stand-off: mortar joint, the shear with lever arm is assumed (EN 1992-4 – Cl. 7.2.2.3.2):

\[V_{Rk,s}= \frac{\alpha_M \cdot M_{Rk,s}}{l_a}\]

where:

- k6 = 0.6 for anchors with fuk ≤ 500 MPa; k6 = 0.5 otherwise

- As – shear area of anchor; if shear plane in a thread is selected, the area reduced by threads is used; otherwise, full shank area is used

- fuk – anchor bolt ultimate strength

- αM = 2 – full restraint is assumed (EN 1992-4 – Cl. 6.2.2.3)

- \( M_{Rk,s} = M_{Rk,s}^0 \left ( 1 - \frac{N_{Ed}}{N_{Rd,s}} \right ) \) – characteristic bending resistance of the anchor decreased by the tensile force in the anchor

- MRk,s0 = 1.2 Wel fub – characteristic bending resistance of the anchor (ETAG 001, Annex C – Equation (5.5b))

- \( W_{el} = \frac{\pi d^3}{32}\) – section modulus of the anchor

- d – anchor bolt diameter; if the shear plane in a thread is selected, the diameter reduced by threads is used; otherwise, nominal diameter, dnom, is used

- NEd – tensile force in the anchor

- NRd,s – tensile resistance of the anchor

- la = 0.5 dnom + tmortar + 0.5 tbp – lever arm

- tmortar – thickness of mortar (grout)

- tbp – thickness of the base plate

- γMs = 1.0 ∙ fuk / fyk ≥ 1.25 for fuk ≤ 800 MPa and fyk / fuk ≤ 0.8; γMs = 1.5 otherwise – partial safety factor for steel failure (EN 1992-4 – Table 4.1)

Concrete pry-out failure (EN 1992-4 – Cl. 7.2.2.4):

\[ V_{Rd,cp}= \frac{V_{Rk,cp}}{\gamma_{Mc}} \]

where:

- VRk,cp = k8 ∙ NRk,c – characteristic resistance of concrete pry-out failure

- k8 = 1 for hef < 60 mm; k8 = 2 for hef ≥ 60 mm (ETAG 001, Annex C – Cl. 5.2.3.3)

- NRk,c – characteristic resistance of a fastener, a group of fasteners, and the tensioned fasteners of a group of fasteners in case of concrete cone failure; all anchors are assumed to be in tension

- γMc = γc – partial safety factor (EN 1992-4 – Table 4.1, γinst = 1.0 for shear loading)

- γc – partial safety factor for concrete (editable in Code setup)

Concrete edge failure (EN 1992-4 – Cl. 7.2.2.5):

Concrete edge failure is a brittle failure, and the worst possible case is checked, i.e. only the anchors located near the edge transfer the full shear load acting on a whole base plate. If anchors are positioned in a rectangular pattern, the row of anchors at the investigated edge transfers the shear load. If anchors are positioned irregularly, the two anchors nearest to the investigated edge transfer the shear load. Two edges in the direction of the shear load are investigated, and the worst case is shown in the results.

Investigated edges in dependence on the direction of the shear force resultant

\[ V_{Rd,c} = \frac{V_{Rk,c}}{\gamma_{Mc}} \]

where:

- \( V_{Rk,c}= V_{Rk,c}^0 \cdot \frac{A_{c,V}}{A_{c,V}^0} \cdot \psi_{s,V} \cdot \psi_{h,V} \cdot \psi_{ec,V} \cdot \psi_{\alpha,V} \cdot \psi_{re,V} \) – characteristic resistance of a fastener or a group of fasteners loaded towards the edge

- \( V_{Rk,c}^0 = k_9 \cdot d_{nom}^\alpha \cdot l_f^\beta \cdot f_{ck}^{0.5} \cdot c_1^{1.5}\) – initial value of the characteristic resistance of a fastener loaded perpendicular to the edge

- k9 – factor taking into account concrete condition; k9 = 1.7 for cracked concrete, k9 = 2.4 for non-cracked concrete

- \( \alpha = 0.1 \left ( \frac{l_f}{c_1} \right ) ^{0.5} \)

- \( \beta = 0.1 \left ( \frac{d_{nom}}{c_1} \right ) ^{0.2} \)

- lf = min (hef, 12 dnom) for dnom ≤ 24 mm; lf = min [hef, max (8 dnom, 300 mm)] for dnom > 24 mm – effective length of the anchor in shear

- hef – embedment depth of the anchor in concrete

- c1 – distance from the anchor to the investigated edge; for fastenings in a narrow, thin member, the effective distance \( c'_1=\max \left \{ \frac{c_{2,max}}{1.5}, \, \frac{h}{1.5}, \, \frac{s_{2,max}}{3} \right \} \) is used instead

- c2 – smaller distance to the concrete edge perpendicular to the distance c1

- dnom – nominal anchor diameter

- Ac,V0 = 4.5 c12 – area of a concrete cone of an individual anchor at the lateral concrete surface not affected by edges

- Ac,V – actual area of the concrete cone of the anchorage at the lateral concrete surface

- \(\psi_{s,V} = 0.7+0.3 \frac{c_2}{1.5 c_1} \le 1.0 \) – factor which takes account of the disturbance of the distribution of stresses in the concrete due to further edges of the concrete member on the shear resistance

- \( \psi_{h,V} = \left ( \frac{1.5 c_1}{h} \right ) ^ {0.5} \ge 1.0 \) – factor which takes account of the fact that the shear resistance does not decrease proportionally to the member thickness as assumed by the ratio Ac,V / Ac,V0

- \( \psi_{ec,V} = \frac{1}{1+2 e_V / (3c_1)} \le 1 \) – factor which takes account of a group effect when different shear loads are acting on the individual anchors of a group

- \( \psi_{\alpha,V} = \sqrt{\frac{1}{(\cos \alpha_V)^2 + (0.5 \sin \alpha_V)^2}} \ge 1 \) – takes account of the angle αV between the load applied, V, and the direction perpendicular to the free edge of the concrete member

- ψre,V = 1.0 – factor takes account of the effect of the type of reinforcement used in cracked concrete

- h – concrete block height

- γMc = γc – partial safety factor (EN 1992-4 – Table 4.1, γinst = 1.0 for shear loading)

- γc – partial safety factor for concrete (editable in Code setup)

Interaction of tension and shear in steel (EN 1993-1-8 – Table 3.4)

The interaction of tension and shear for cast-in anchors is determined separately for steel and concrete. Steel failure mode is checked according to EN 1993-1-8 – Table 3.4. The interaction in steel is checked for each anchor separately.

\[ \frac{V_{Ed}}{F_{v,Rd}} + \frac{N_{Ed}}{1.4 \cdot F_{t,Rd}} \le 1.0 \]

Interaction of tension and shear in steel (EN 1992-4 – Table 7.3)

The interaction of tension and shear for post-installed fasteners is determined separately for steel and concrete failure modes according to Table 7.3. Interaction in steel is checked according to Equation (7.54). The interaction in steel is checked for each anchor separately.

\[ \left ( \frac{N_{Ed}}{N_{Rd,s}} \right )^2 + \left ( \frac{V_{Ed}}{V_{Rd,s}} \right )^2 \le 1.0 \]

Interaction of tension and shear in concrete

Interaction in concrete is checked according to Equation (7.55).

\[ \left ( \frac{N_{Ed}}{N_{Rd,i}} \right )^{1.5} + \left ( \frac{V_{Ed}}{V_{Rd,i}} \right )^{1.5} \le 1.0 \]

The largest value of \(N_{Ed} / N_{Rd,i} \) and \(V_{Ed} / V_{Rd,i} \) for the different failure modes shall be taken. Note that values of \(N_{Ed}\) and \(N_{Rd,i}\) often belong to a group of anchors.

Anchors with stand-off

An anchor with stand-off is designed as a bar element loaded by shear force, bending moment, and compressive or tensile force. These internal forces are determined by the finite element model. The anchor is fixed on both sides, one side is 0.5×d below the concrete level, and the other side is in the middle of the thickness of the plate. The buckling length is conservatively assumed as twice the length of the bar element. Plastic section modulus is used. The bar element is designed according to EN 1993-1-1. The shear force may decrease the yield strength of the steel according to Cl. 6.2.8 but the minimum length of the anchor to fit the nut under the base plate ensures that the anchor fails in bending before the shear force reaches half the shear resistance. The reduction is therefore not necessary. The interaction of bending moment and compressive or tensile strength is assessed according to Cl. 6.2.1.

Shear resistance (EN 1993-1-1 Cl. 6.2.6):

\[ V_{pl,Rd} = \frac{A_V f_y / \sqrt{3}}{\gamma_{M2}} \]

where:

- AV = 0.844 As – shear area

- As – bolt area reduced by threads

- fy – bolt yield strength

- γM2 – partial safety factor

Tensile resistance (EN 1993-1-8 – Cl. 3.6.1):

\[ F_{t,Rd}=\frac{c k_2 f_{ub} A_s}{\gamma_{M2}} \ge F_t \]

where:

- c – decrease in tensile resistance of bolts with cut thread according to EN 1993-1-8 – Cl. 3.6.1. (3) editable in Code setup

- k2 = 0.9 – factor from Table 3.4 in EN 1993-1-8

- fub – anchor bolt ultimate strength

- As – anchor bolt tensile stress area

- γM2 – safety factor (EN 1993-1-8 – Table 2.1; editable in Code setup)

Compressive resistance (EN 1993-1-1 Cl. 6.3):

\[ F_{c,Rd} = \frac{\chi A_s f_y}{\gamma_{M2}} \]

where:

- \( \chi = \frac{1}{\Phi + \sqrt{\Phi^2 - \bar\lambda^2}} \le 1 \) – buckling reduction factor

- \( \Phi = 0.5 \left [1+ \alpha (\bar\lambda - 0.2) + \bar\lambda^2 \right ] \) – value to determine buckling reduction factor χ

- α = 0.49 – imperfection factor for buckling curve c (belonging to the full circle)

- \( \bar\lambda = \sqrt{\frac{A_s f_y}{N_{cr}}} \) – relative slenderness

- \( N_{cr} = \frac{\pi^2 E I}{L_{cr}^2} \) – Euler's critical force

- \( I = \frac{\pi d_s^4}{64} \) – moment of inertia of the bolt

- Lcr = 2 l – buckling length; it is assumed on the safe side that the bolt is fixed in the concrete and able to rotate at the base plate freely

- l – length of the bolt element equal to half the base plate thickness + gap + half the bolt diameter; it is assumed on the safe side that the washer and a nut are not clamped to the concrete surface (ETAG 001 – Annex C – Cl. 4.2.2.4)

Bending resistance (EN 1993-1-1 Cl. 6.2.5):

\[ M_{pl,Rd} = \frac{W_{pl} f_y}{\gamma_{M2}} \]

- \( W_{pl}= \frac{d_s^3}{6} \) – section modulus of the bolt

- fy – bolt yield strength

- γM2 – partial safety factor

Anchor steel utilization (EN 1993-1-1 Cl. 6.2.1)

\[ \frac{N_{Ed}}{N_{Rd}} + \frac{M_{Ed}}{M_{Rd}} \le 1 \]

where:

- NEd – tensile (positive) or compressive (negative sign) design force

- NRd – tensile (positive, Ft,Rd) or compressive (negative sign, Fc,Rd) design resistance

- MEd – design bending moment

- MRd = Mpl,Rd – design bending resistance

Detailing

A detailing check of anchors is performed if the option is selected in the Code setup. Only minimum spacing between anchors (measured centreline to centreline) is checked. The minimum spacing differs for each anchor type and is given in the European Technical Product Specification. Users can modify limit spacing value in the Code setup as a multiple of anchor bolt diameter.

Edge distances to steel plates follow the rules for bolts, i.e. e = 1.2 is recommended in Table 3.3 in EN 1993-1-8. User can modify this value in Code setup.