Prying and high tension force in bolts

Why is the tension force in a bolt higher than expected by a hand calculation? Why are there tension forces in bolts in a fin plate connection? Why are the tension forces in bolts sometimes different for each bolt grade?

The common answer is the CBFEM model used in IDEA StatiCa applications. The deformation of plates and other parts is calculated as a part of the finite elements analysis, and thus the prying forces come into action. The prying forces are the extra loads also introduced to the bolts.

As a result of the prying forces, the resulting tension forces in bolts may vary a lot depending on the design of the connection, the strength of the connection parts, and applied load effects.

Tension forces in bolts of a fin plate connection

In most cases, fin plates use one plate to connect the member. The consequence of this is, that we apply small eccentricity to the connection. This eccentricity will cause additional prying forces on plates, which induces tension in bolts.

If a double-sided fin plate is used, and the connection is symmetrical, the only tension forces in bolts appear due to the deformation of fin plates because, with the deformations, additional eccentricity is produced.

Higher tension forces in bolts of an end plate connection

The thinner the end plate is, the more deformation under the given load effects it has. This adds the prying action and additional tensile forces are applied to bolts. If the end plate is thick and thus stiff enough, the prying forces are eliminated. See this effect demonstrated in a simple example:

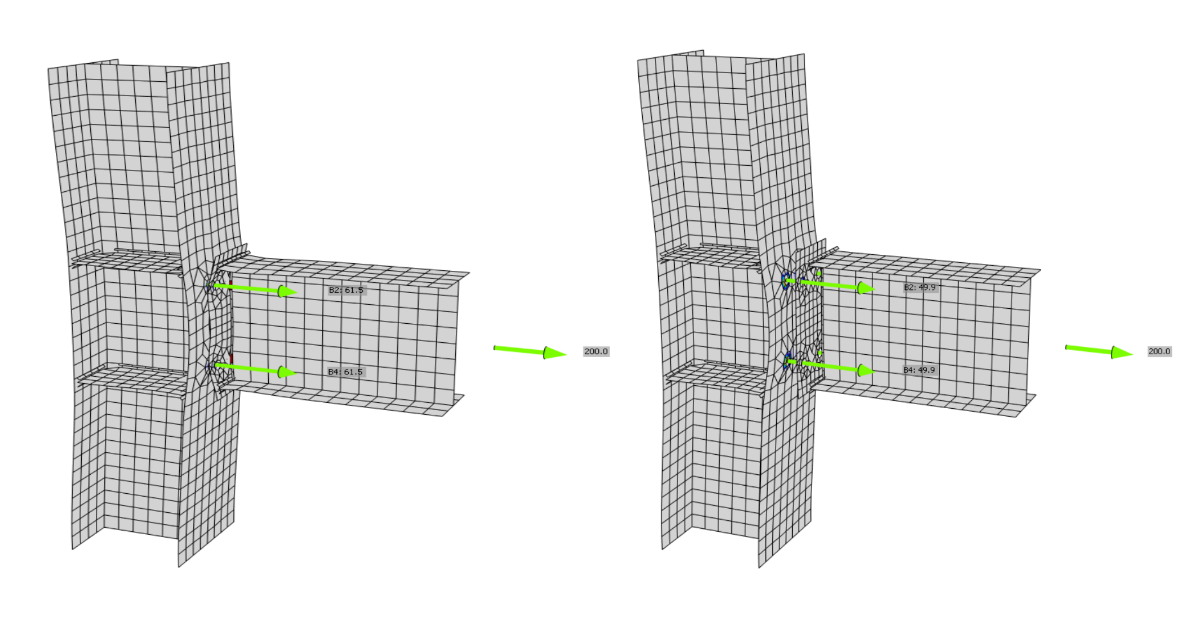

a) Endplate - thickness 10 mm, applied tension force 200 kN

Resultant tension force in 4 bolts: 61.5 x 4 = 246 kN

b) Endplate - thickness 40 mm, applied tension force 200 kN

Resultant tension force in 4 bolts: 49.9 x 4 = 200 kN

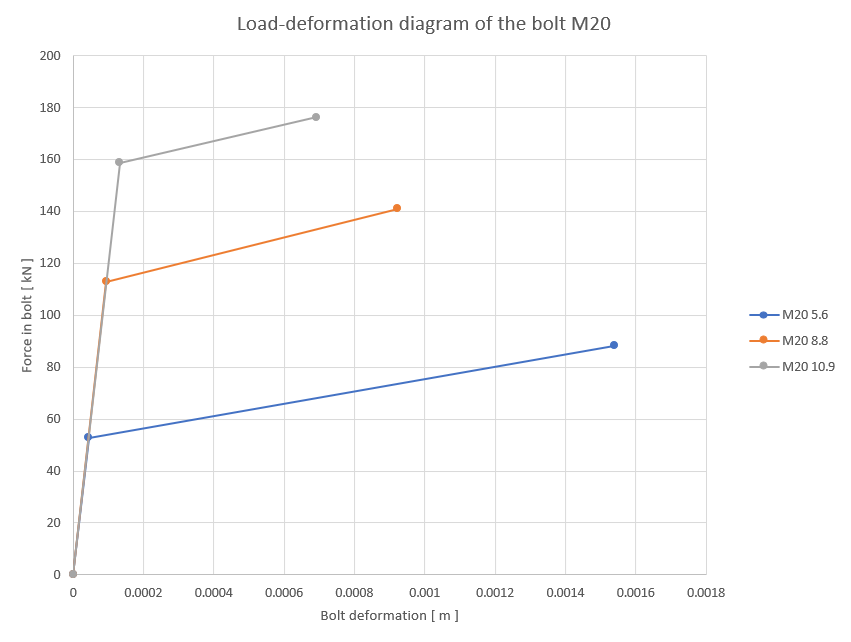

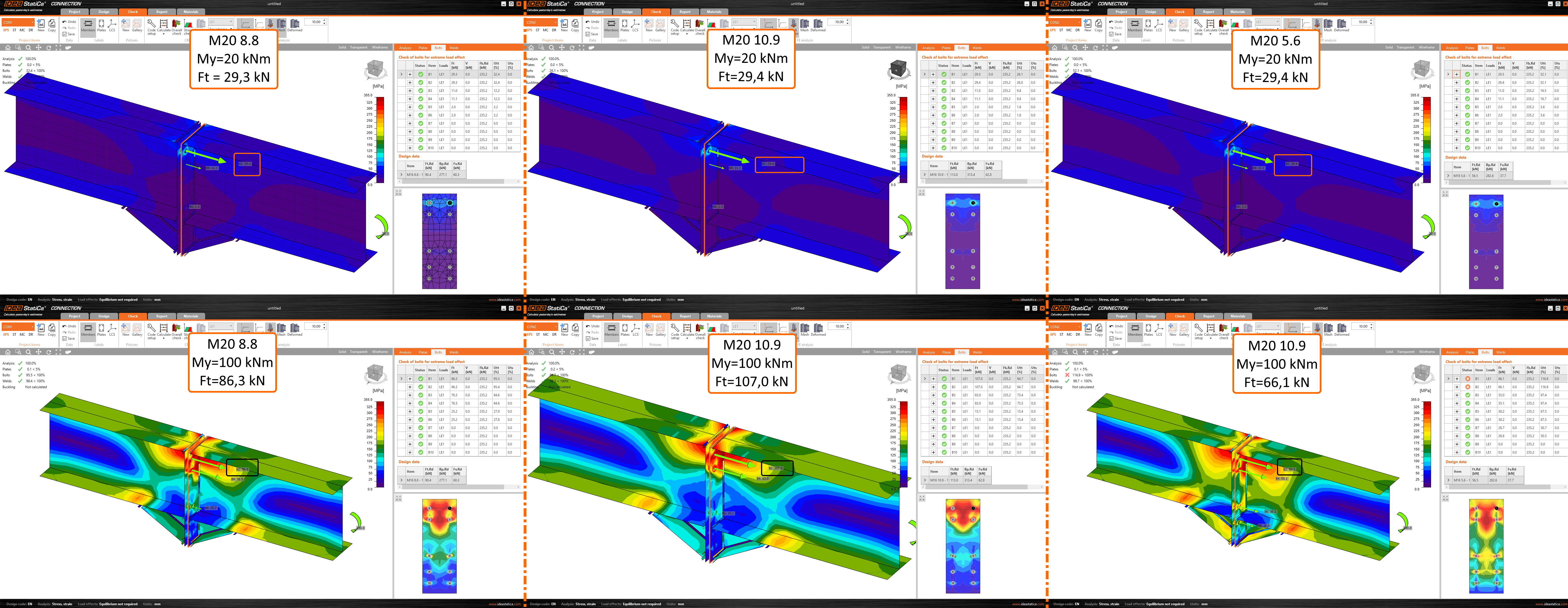

Different tension forces in bolts by the bolt grade

Each bolt grade has a different working diagram and different values of yield strength. In an endplate connection of two beams loaded by a bending moment, the comparison of three different bolt grades (8.8, 10.9, and 5.6) of an M20 bolt is demonstrated.

For relatively low load effects the resulting tension forces in bolts per each grade show similar values.

But for load effects that result in high utilization of bolts (and plastification in bolts), the tension force varies depending on the bolt grade. The higher the bolt grade, the higher the resulting tension force.

For more information, see the theoretical background and the video recording.