Learning Module: Load Path and Failure Modes of Fixed connections (EN)

Connection design can be difficult to teach, given the detailed nature of the topic and the fundamentally three-dimensional behavior of most connections. However, connections are critically important, and lessons learned in the study of connection design, including load path and identification and evaluation of failure modes, are general and applicable to structural design broadly. IDEA StatiCa uses a rigorous nonlinear analysis model and has an easy-to-use interface with a three-dimensional display of results (e.g., deformed shape, stress, plastic strain) and thus is well suited for the exploration of the behavior of structural steel connections. Building on these strengths, a suite of guided exercises that use IDEA StatiCa as a virtual laboratory to help students learn about concepts in structural steel connection behavior and design was developed. These learning modules were primarily targeted to advanced undergraduate and graduate students but were made suitable for practicing engineers as well. The learning modules were developed by Associate Professor Mark D. Denavit from the University of Tennessee, Knoxville.

This learning module is derived from Learning Module: Load Path and Failure Modes of Fully Restrained Moment Connections (AISC) and modified for Eurocode by Assistant Professor Martin Vild from Brno university of Technology.

Learning Objective

After performing this exercise, the learner should be able to describe the load path for a fixed connection and identify relevant failure modes.

Background

Load Path

Loads applied to a structure are transferred through members and connections before eventually being resisted by the ground. Tracking the path of the load from its point of load application to the ground can be a helpful qualitative exercise to ensure the path is continuous, and that each component along the path has sufficient stiffness and strength. Tracking a subset of the load path through a connection provides the same benefits.

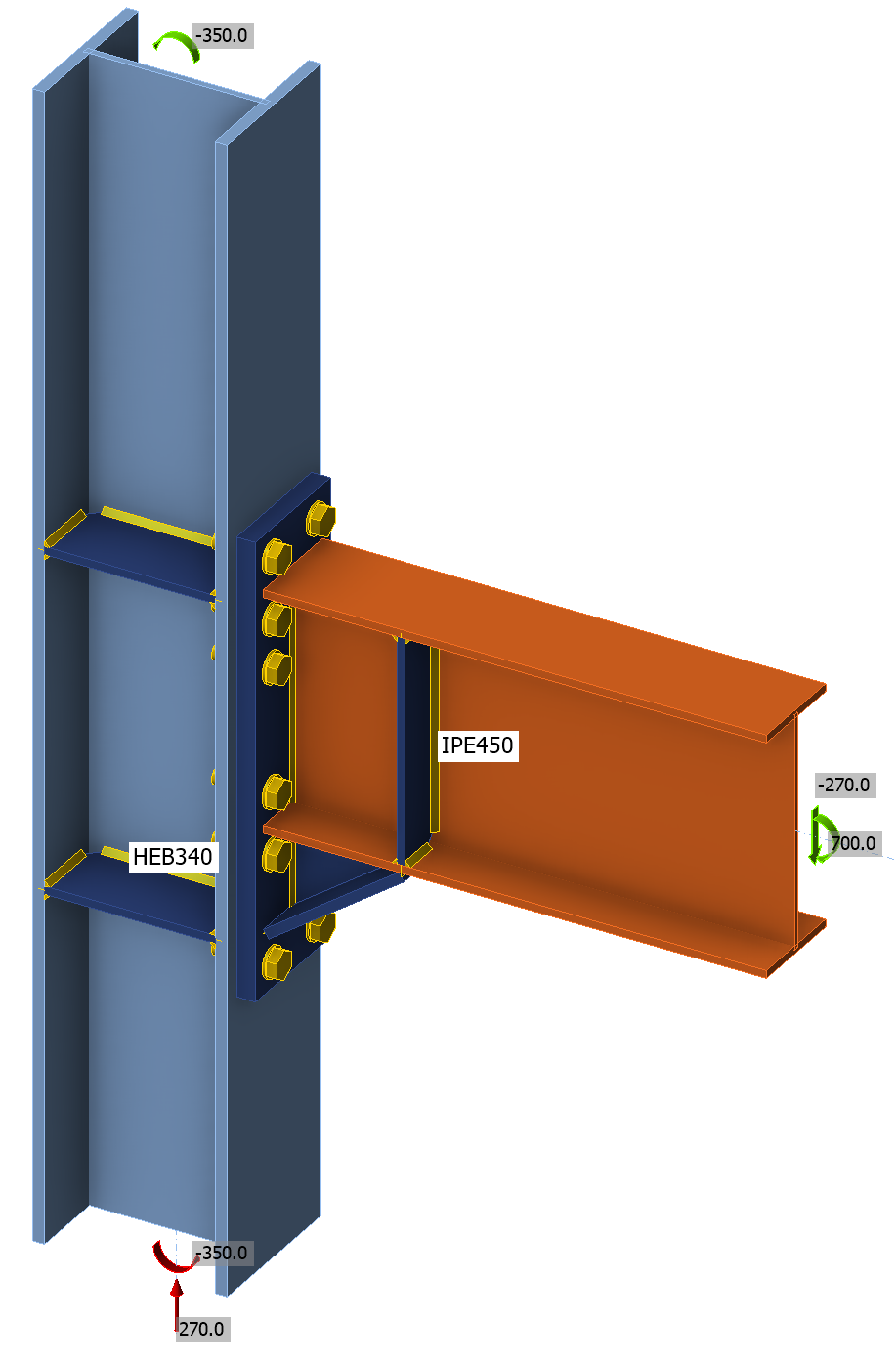

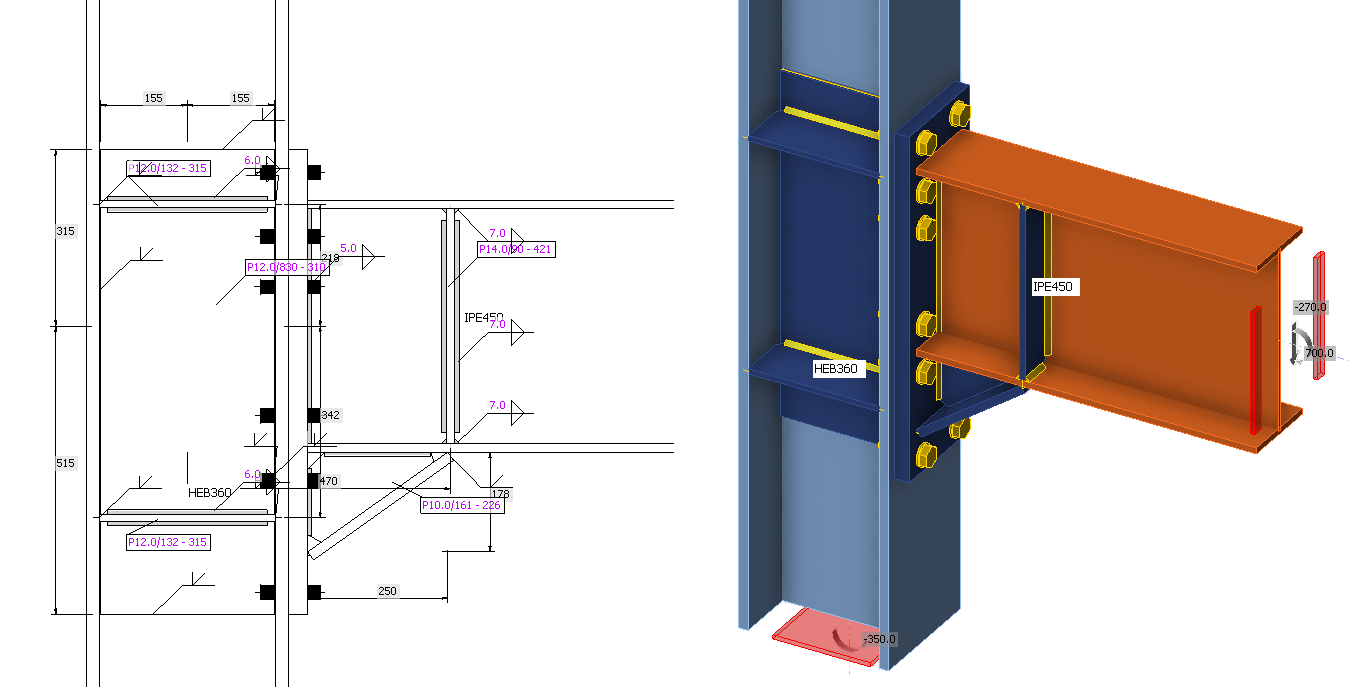

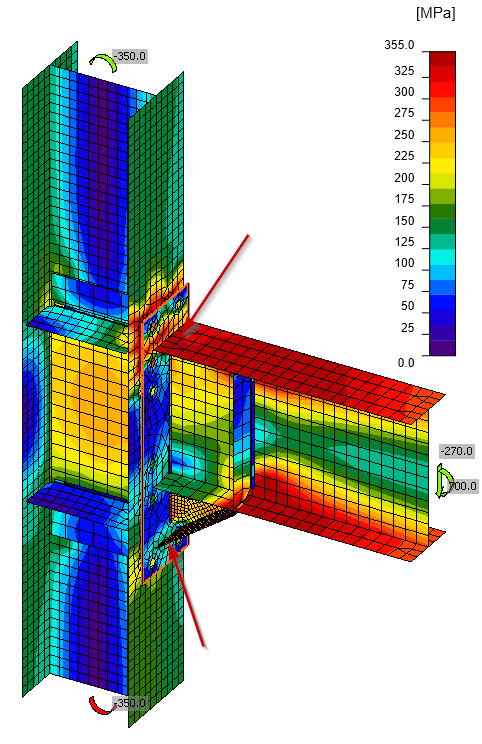

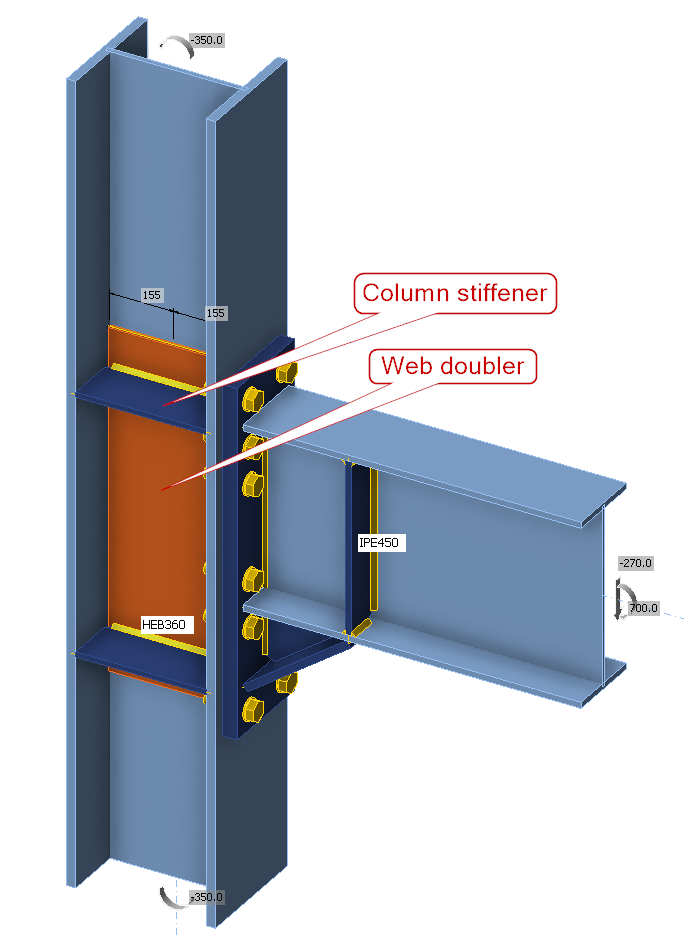

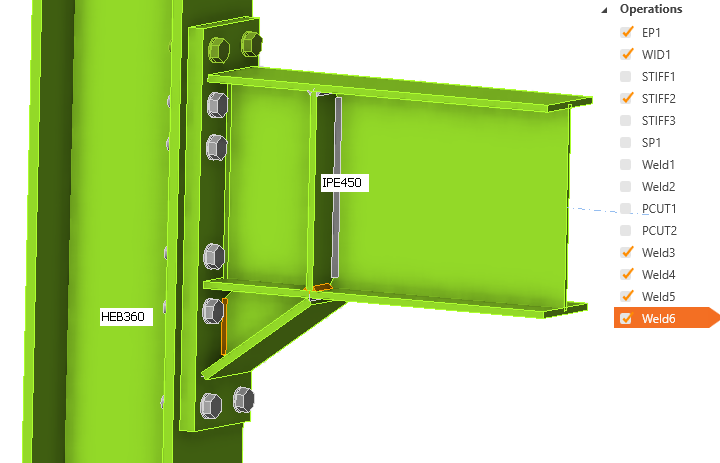

Consider, for example, the steel I-section beam-to-column fixed connection shown below. This connection is inspired by Equaljoints project for seismic applications. Moment in the beam is transferred to the column as follows:

- At the end of the beam, moment concentrates to the beam flanges, which are then subject to tension and compression.

- The haunch is added to increase the lever arm and thus the bending resistance. The bending moment is the highest in the node, and thanks to the shear force, it continually decreases. The stresses due to bending moment flow primarily through the top flange and the flange of the haunch.

- The shear stress flows through the beam web and the haunch web where the stiffness against vertical load is the highest.

- From the beam and the haunch, the load is distributed into the end plate by butt welds.

- The beam flange to column flange welds transfer the beam flange forces to the column flange.

- The shear force is transferred via shear in bolts to the column flange and the bending moment via the lever arm of two forces – tension through the bolt tension in the bolt rows near the top flange and compression via contact between end plate and the column flange.

- Column stiffeners add to the strength and stiffness of the column against concentrated loads where they are expected to be the highest, i.e. at the beam top flange and hauch bottom flange.

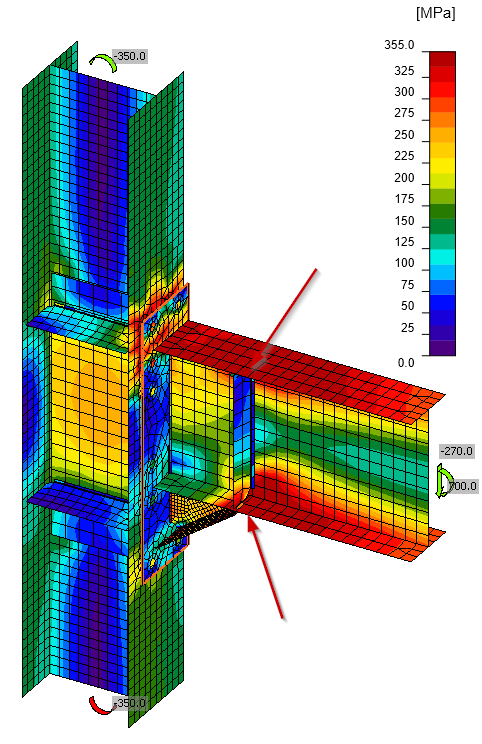

- The load from end plate bolts and stiffener welds spreads through the column cross-section, resulting in shear in the panel zone and moment in the column.

In traditional connection design, load paths such as this can help engineers develop a checklist of limit states and to ensure every step along the path has sufficient stiffness and strength. In design by inelastic analysis, load paths can help engineers by providing a mental model of connection behavior against which the results of numerical analyses can be compared.

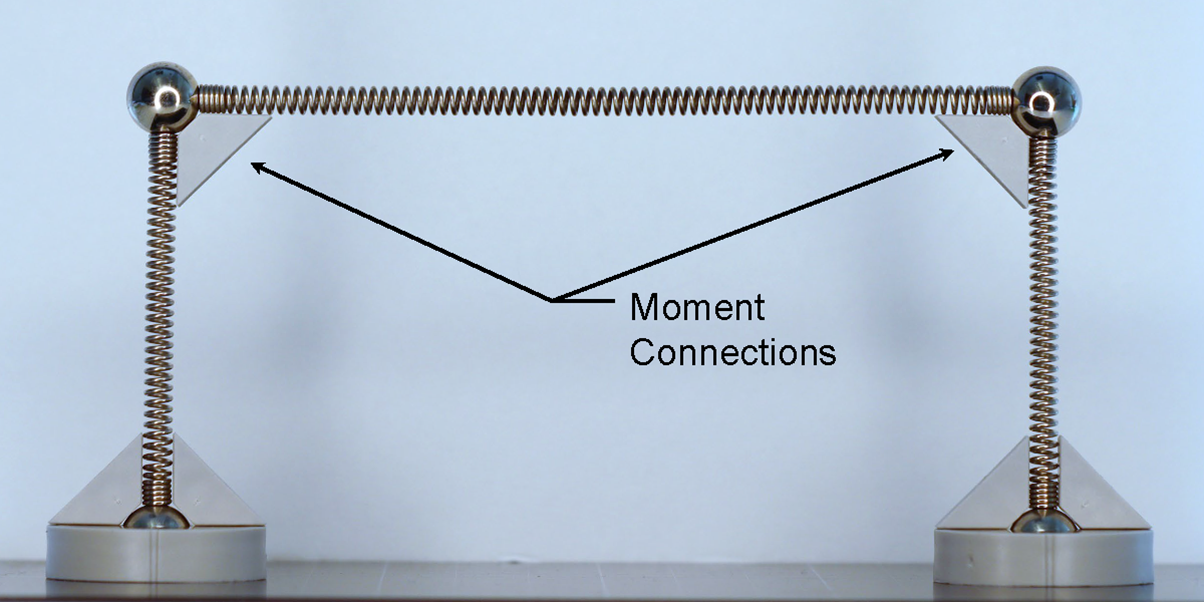

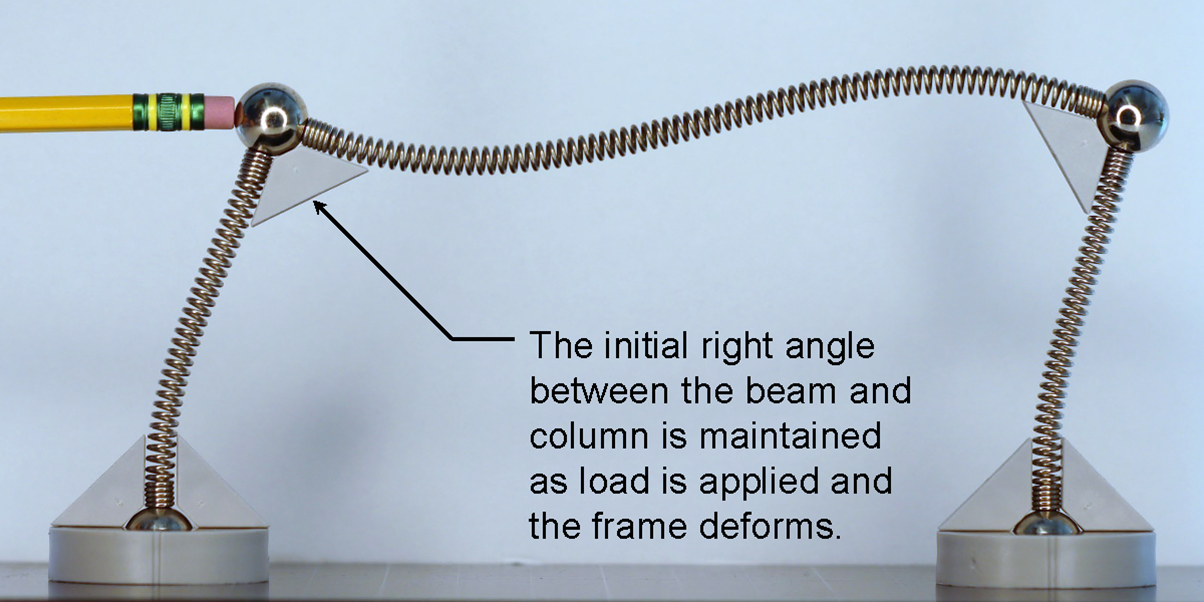

Moment Connections

One of the major classifications of connections at the ends of beams is based on rotational stiffness. Simple shear connections are flexible enough to assume no moment is transmitted through the connection. Moment connections, on the other hand, transmit moment between the beam and column. Fully restrained connections are stiff enough to assume that no relative rotation occurs between members when transmitting the moment. Moment connections enable the beams and columns to form a moment frame that can serve as a lateral load-resisting system.

Moment frame action demonstrated with components from a Mola Structural Kit

Since most of the moment in a wide flange beam is resisted by the flanges, moment connections must engage the flanges of the beam directly. Moment connections typically also transfer shear or other forces from the beam to the column and thus also typically engage the web of the beam directly too. As a result, moment connections are generally statically indeterminate and the true distribution of stresses in the connection depends on the relative stiffness of the various components.

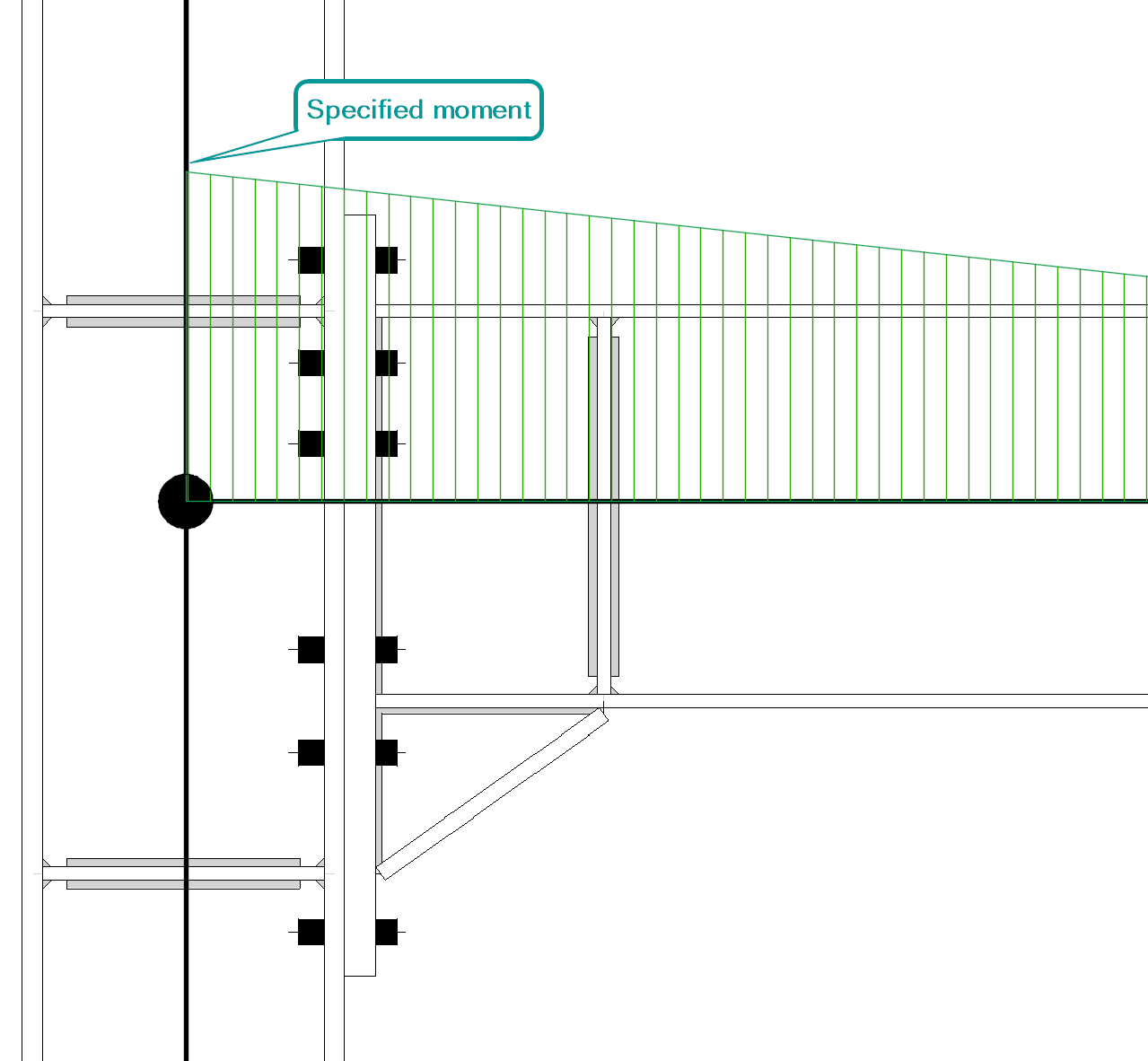

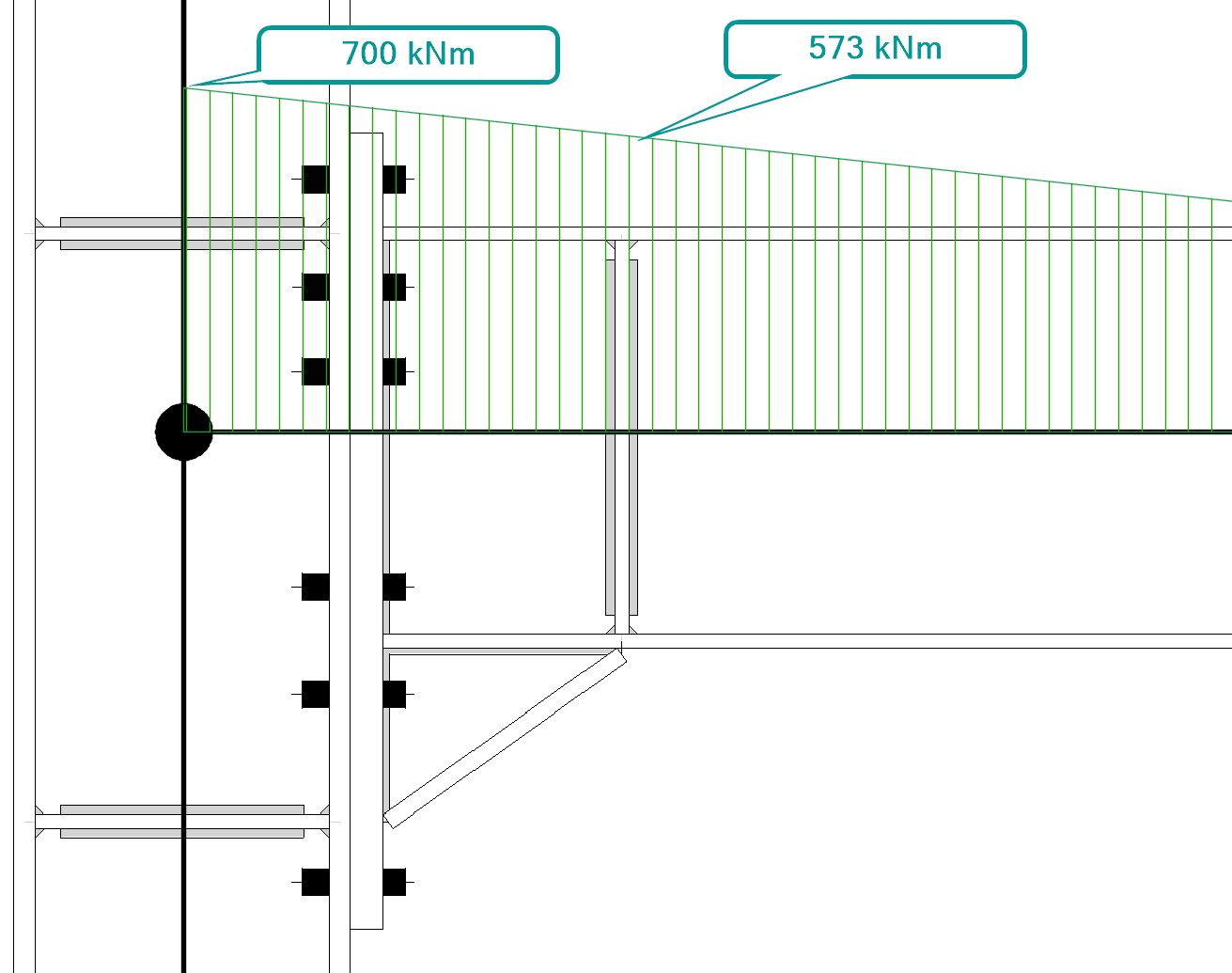

Shear forces induce a moment gradient in the beam. For moment connections, such as flange plate connections, that occur over a length of the beam, the moment is not constant. In hand calculations, the moment gradient is often conservatively neglected, and a single value of moment is used regardless of the length of the connection. The moment gradient cannot be neglected in IDEA StatiCa since the analyses ensure equilibrium and thus must be properly defined to be consistent with the structural analysis from which the required strengths were obtained. The specified moment will occur where defined by the “Forces in” option in the member menu.

Connection

The examined connections are inspired by Equaljoints project. The haunched joint is selected for the first connection.

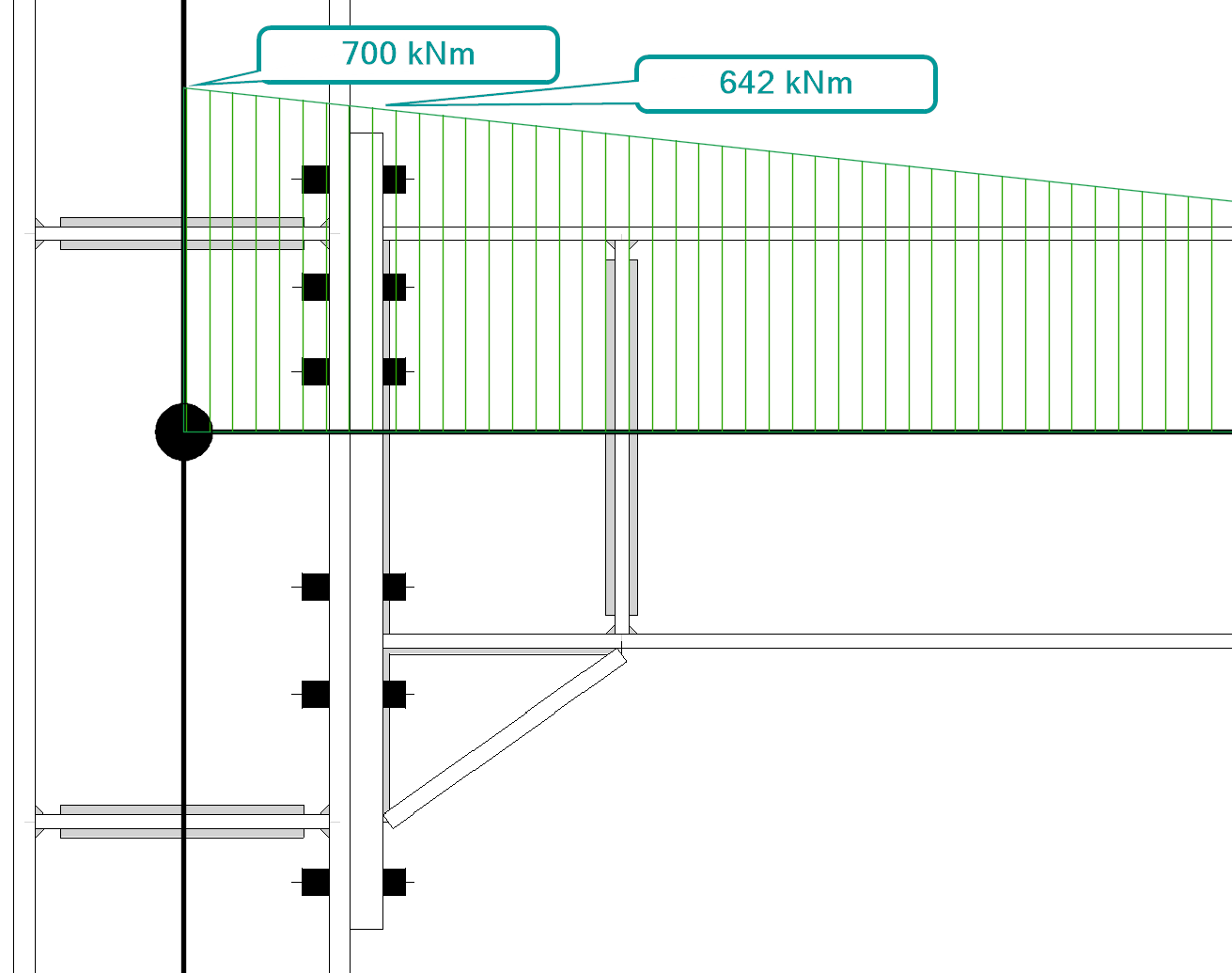

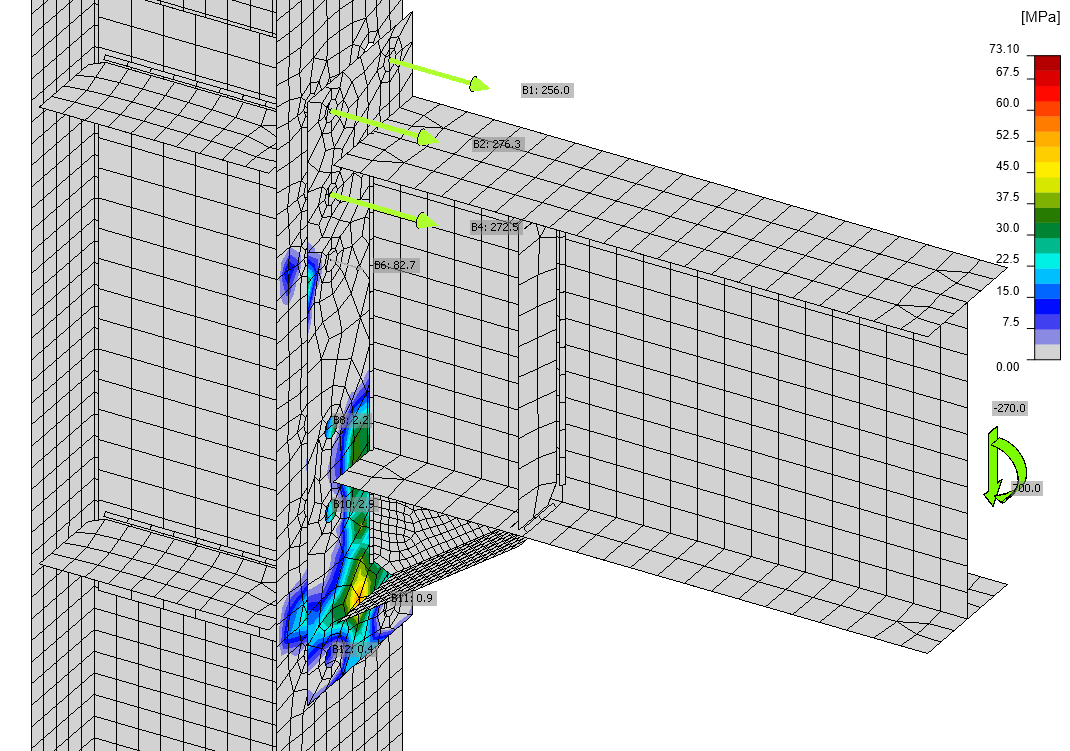

This connection is loaded by design shear force 270 kN and design bending moment 700 kNm. The loads are specified in node.

Procedure

The procedure for this exercise assumes that the learner has a working knowledge of how to use IDEA StatiCa (e.g., how to navigate the software, define and edit operations, perform analyses, and look up results). Guidance for how to develop such knowledge is available on the IDEA StatiCa website.

Retrieve the IDEA StatiCa file for the example connection provided with this exercise. Open the file in IDEA StatiCa. To perform the exercise, follow the narrative, complete the tasks, and answer the questions.

Load Path

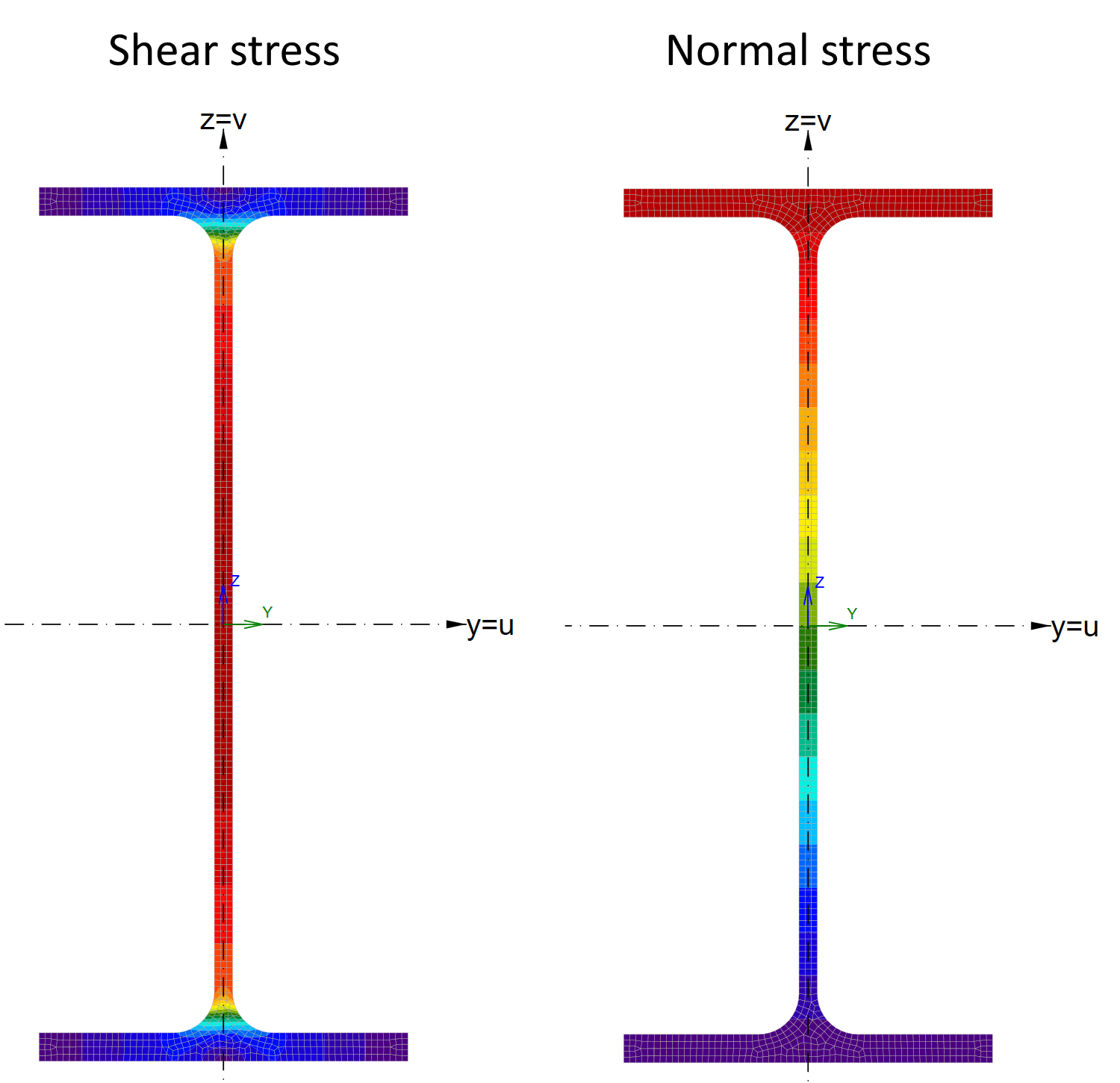

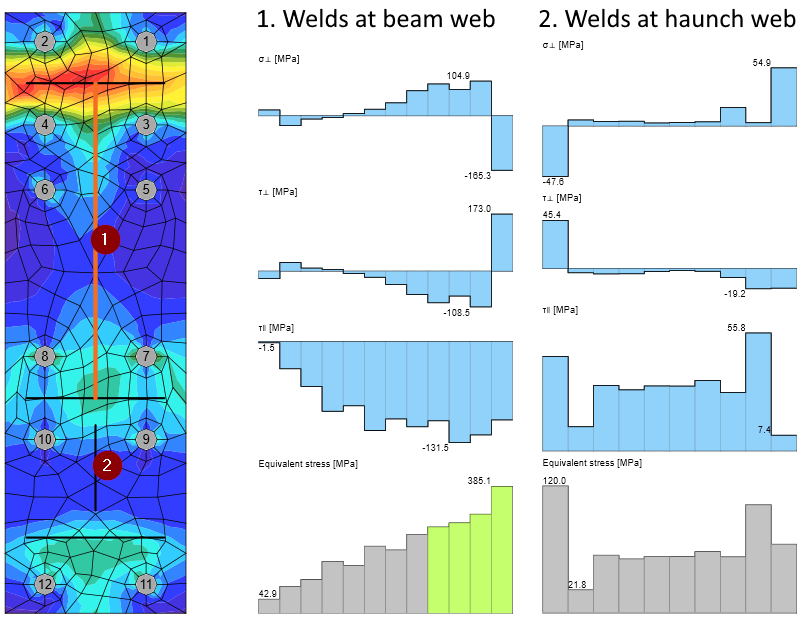

The load path for shear transferring from the beam to the column is as follows:

- Shear is concentrated at the beam web.

- Shear flows through welds by shear perpendicular stresses, \(\tau_\perp\), to the end plate.

- Through the end plate, the load is distributed into the bolts.

- Via shear stresses in bolts, the shear is transferred to the column flange and then by normal force in the column into the ground.

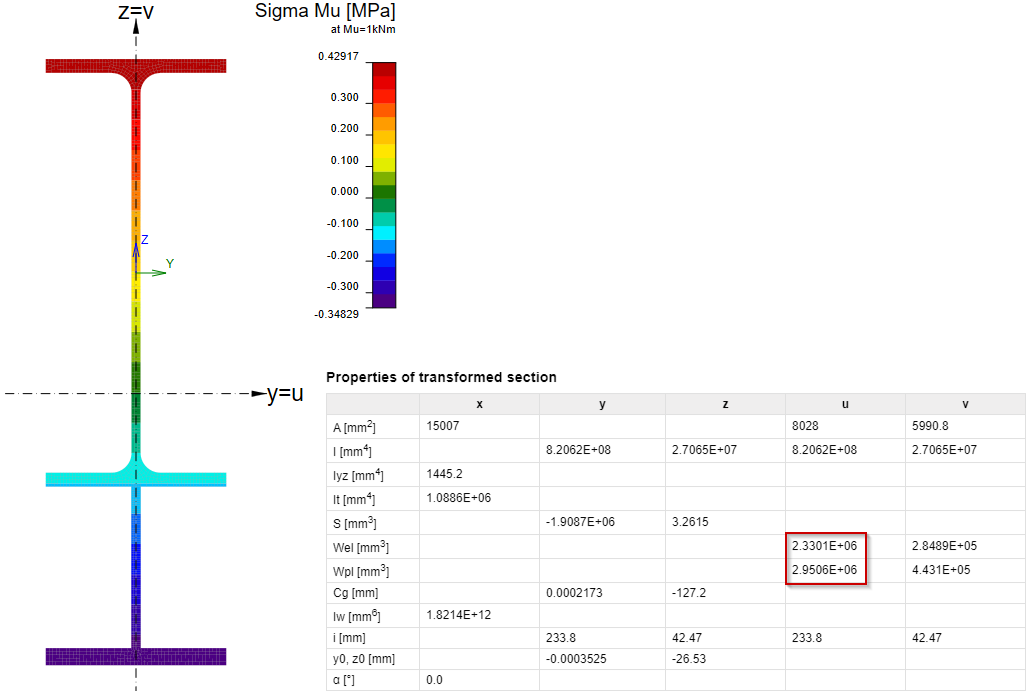

Shear stresses caused by unit shear force and normal stresses caused by unit bending moment at elastic stage

The load path for the bending moment transferring from the beam to the column is as follows:

- Moment concentrates mostly to the beam flanges, which are then subject to tension and compression.

- The haunch is added to increase the lever arm and thus the bending resistance. The bending moment is the highest in the node, and thanks to the shear force, it continually decreases. The stresses due to bending moment flow primarily through the top flange and the flange of the haunch.

- From the beam and the haunch, the load is distributed into the end plate by butt welds.

- The beam flange to column flange welds transfer the beam flange forces to the column flange.

- The bending moment is transferred via the lever arm of two forces – tension through the bolt tension in the bolt rows near the top flange and compression via contact between end plate and the column flange.

- Column stiffeners add to the strength and stiffness of the column against concentrated loads where they are expected to be the highest, i.e. at the beam top flange and hauch bottom flange.

- The load from end plate bolts and stiffener welds spreads through the column cross-section, resulting in shear in the panel zone and moment in the column.

Beam

The beam is subject to moment; therefore, failure modes such as flexural yielding and lateral-torsional buckling must be investigated as part of the member evaluation. The effect of lateral-torsional buckling may be checked in IDEA StatiCa Member using GMNIA or by code calculation according to EN 1993-1-1 – Cl. 6.3.2. Flexural yielding is in IDEA StatiCa checked against the 5% plastic strain limit. The most dangerous cross-section is at the end of the haunch.

Haunch

Haunch increases the beam cross-section, increasing connection strength and stiffness by increasing lever arm between tension in bolts and the compression center.

End plate

The shear and normal stresses are transferred into the end plate via welds. Full-penetration butt welds are used for critical welds of flanges. Fillet welds are used at the web where the welds are less loaded.

The load is transferred through the end plate into bolts. Typically, it is assumed that the shear forces are distributed evenly into all bolts. Alternatively, the bolts loaded most in tension are excluded and it is assumed that the bolts in compression zone transfer shear force.

The first rows of bolts are loaded by tension and the end plate is in contact with column flange at the haunch flange.

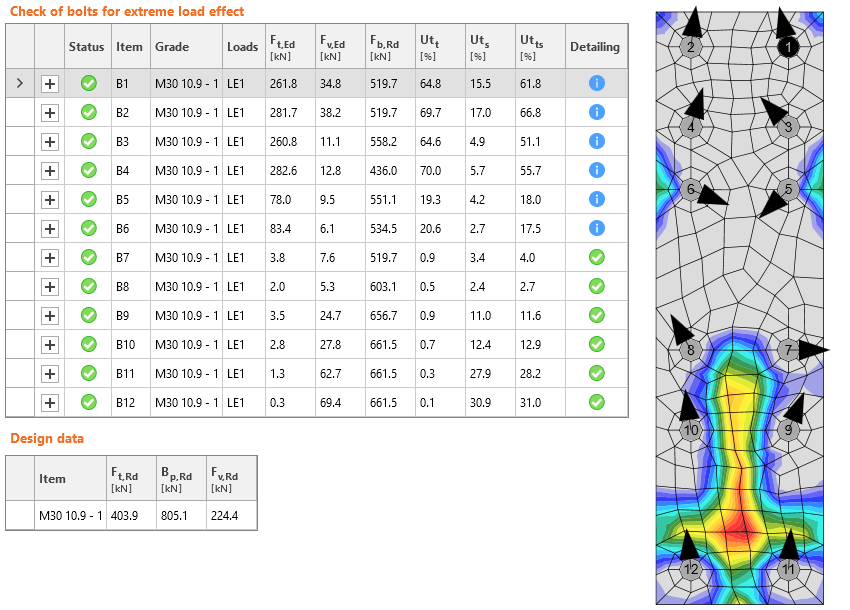

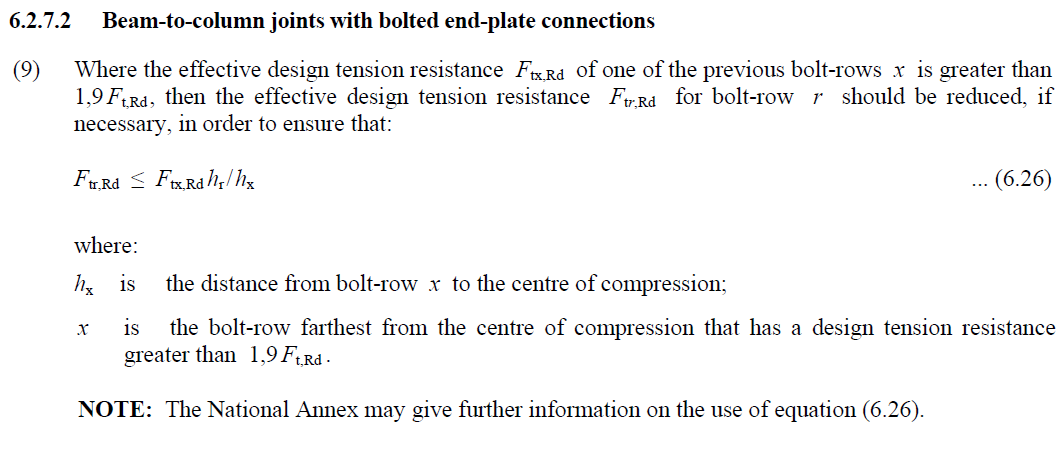

To calculate bending moment by hand, the tensile forces in bolts may be assumed plastically provided Clause 6.2.7.2 (9) is satisfied. Basically mode 1 or 2 (relatively thin end plate or column flange compared to bolts) should govern to ensure ductile behavior.

Column

The load is transferred to the column via tensile and shear forces in end-plate bolts and via contact forces between end plate and column flange.