Why is 5% plastic strain limit used in material diagram for EN?

Common methods

Every structural engineer is used to using the yield strength as the limit value of the check, as basically every standard and design code is based on this approach.

Nevertheless, this applies to the pure elastic behaviour of the material. This can lead to conservative design and sometimes unnecessary overdesigning of the structure, resulting in more material being consumed.

However, the real behaviour of steel is different, and it is okay to assume the plastic behaviour of the material after the yield strength has been exceeded.

IDEA StatiCa and the CBFEM method

Component Based Finite Element Method (CBFEM) is a synergy of the Component Method and Finite Element analysis.

The check of a joint in a standard component based method and in the CBFEM used in IDEA StatiCa Connection is based on the check of all parts of the joint – the components. Components can be bolts, anchors, welds, plates, and concrete at the footing.

CBFEM splits the whole joint into above mentioned separated components. Then the analysis model is created automatically by the software from each component.

All steel plates, like flanges or webs of cross-sections, stiffeners, ribs, haunches, etc., are modeled by finite elements. FEM is widely accepted in structural engineering and brings very good and trusted results.

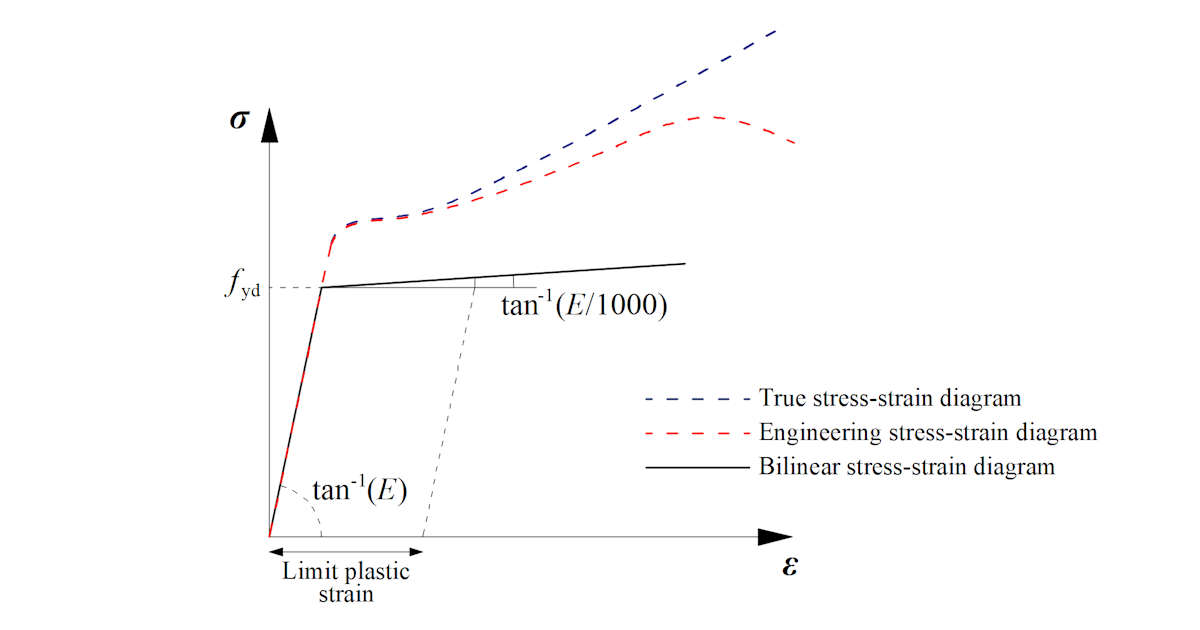

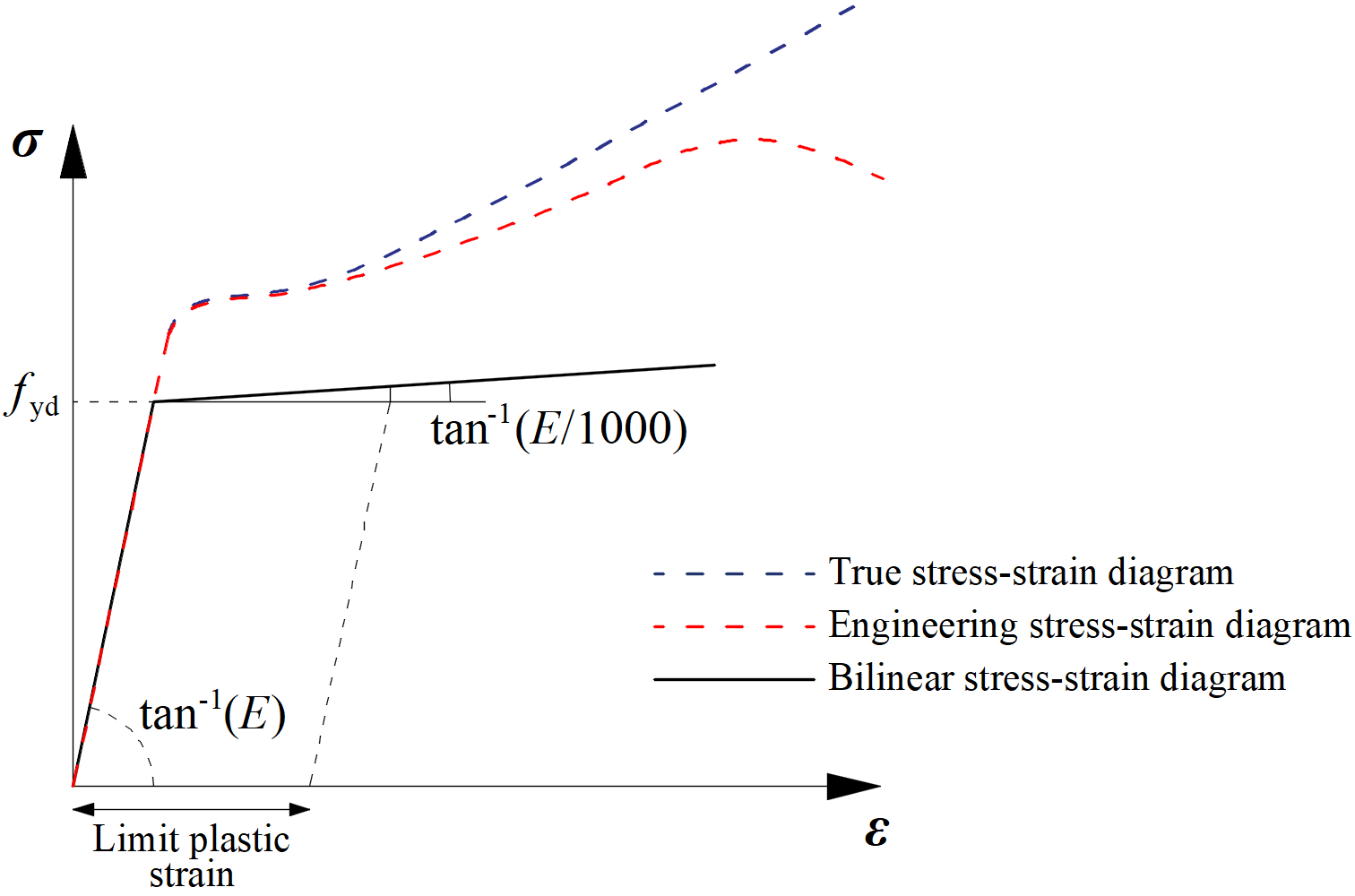

The plates are modeled with elastic-plastic material with a nominal yielding plateau slope according to EN 1993-1-5, Par. C.6, (2), tan-1 (E/1000).

The material behavior is based on the von Mises yield criterion. It is assumed to be elastic before reaching the design yield strength fyd.

The ultimate limit state criterion for regions not susceptible to buckling is reaching the limiting value of the principal membrane strain. A value of 5% is recommended (e.g. EN 1993-1-5, App. C, Par. C.8, Note 1).

To find out more about the method, read the CBFEM - how it works, code compliance, validation and verification article.

Read the essential information about the theory in our Theoretical Background.

Validation and verification

The CBFEM method, with all its assumptions and approaches, such as the 5% limit plastic strain, has been properly validated and verified. What exactly do validation and verification mean? The validation and verification process confirms that the results of the software are correct.

Based on the results, it can be said that it is an absolutely reliable, proven, and safe method.

In our Support Center, you can find many verification studies as well as comparisons to laboratory tests. Find them using the link below.

The most important verification and validation examples were published in the book "Component-based finite element design of steel connections."

Conclusion

Based on the validation of results with 3D solid models in other scientific software, real experiments, and, last but not least, following the recommendations of Eurocode, 5% plastic strain has been set as the limit check value.

This value is sufficient to reach the real behaviour of the structure, achieve an economical design, and stay on the safe side of the design.