Tamahú Bridge

This route is anticipated to be crucial for delivering humanitarian aid to affected communities in the event of a national emergency. Desiderio Caal, President of the Community Development Council (Cocode) of Tamahú, highlighted that the bridge represents a significant opportunity to enhance trade in the Polochic Valley.

The inauguration of the bridge was attended by President Alejandro Giammattei and local authorities, who reported that approximately 120,000 people would benefit from this infrastructural project. This project is included in the large-scale national project Environmental Protection and Disaster Risk Reduction Management of the National Defence Policy 2021-2032.

About the project

It is a full steel bridge assembled on the site, including the steel deck. The structure is a Warren-truss type. The Warren truss comprises longitudinal members connected by angled cross-members, creating a series of alternating inverted equilateral triangles along its length. This design results in a true truss structure, where each strut, beam, or tie is subjected solely to tension or compression forces without any bending or torsional forces acting on them.

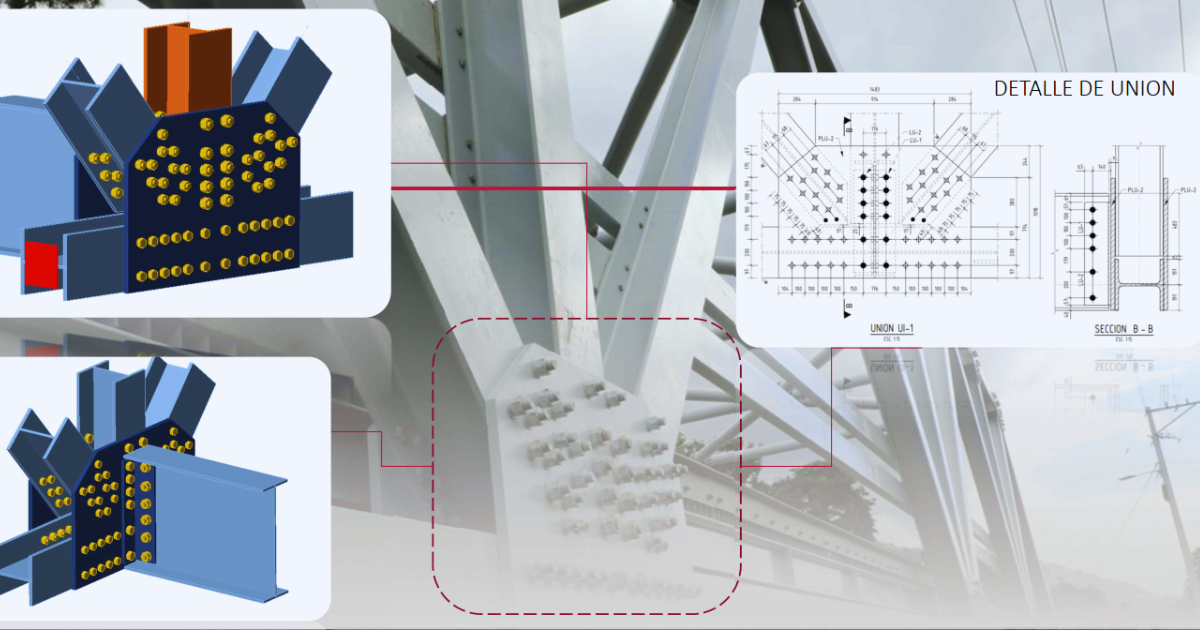

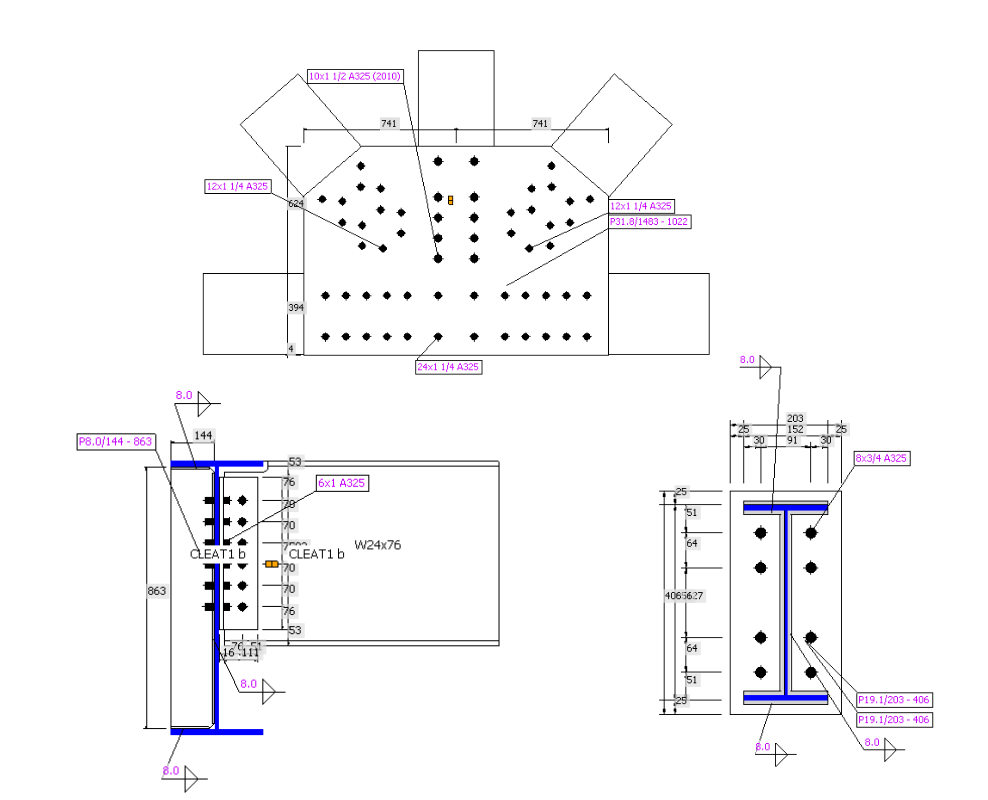

The steel bridge features a combination of I-section diagonals and vertical columns, with circular hollow section (CHS) profiles in the horizontal direction. The joints are assembled using gusset plates connected by bolts, ensuring structural rigidity and stability.

The bridge measures 60.0 meters in length, 9.7 meters in height at the mid-span, and 9.11 meters in width in the bridge section.

The design was done according to AGIES NSE 5.2-2018 (Guatemalan Standards) and AASHTO LRFD Bridge Design.

The superstructure (main structure) and substructure (foundations), as well as the slatted floor system, were designed to facilitate the bridge's lightness and to allow it to be assembled in the shortest possible time.

Engineering challenges

One of the challenges was the time required to assemble the structure since it was an emergency and had to be done in the shortest possible time to improve the road's traffic-carrying ability. Given that the rainy season spans nearly half of the year, a swift construction solution was imperative. Furthermore, the complex geometry of the connection and the stress distribution were critical factors that demanded meticulous attention.

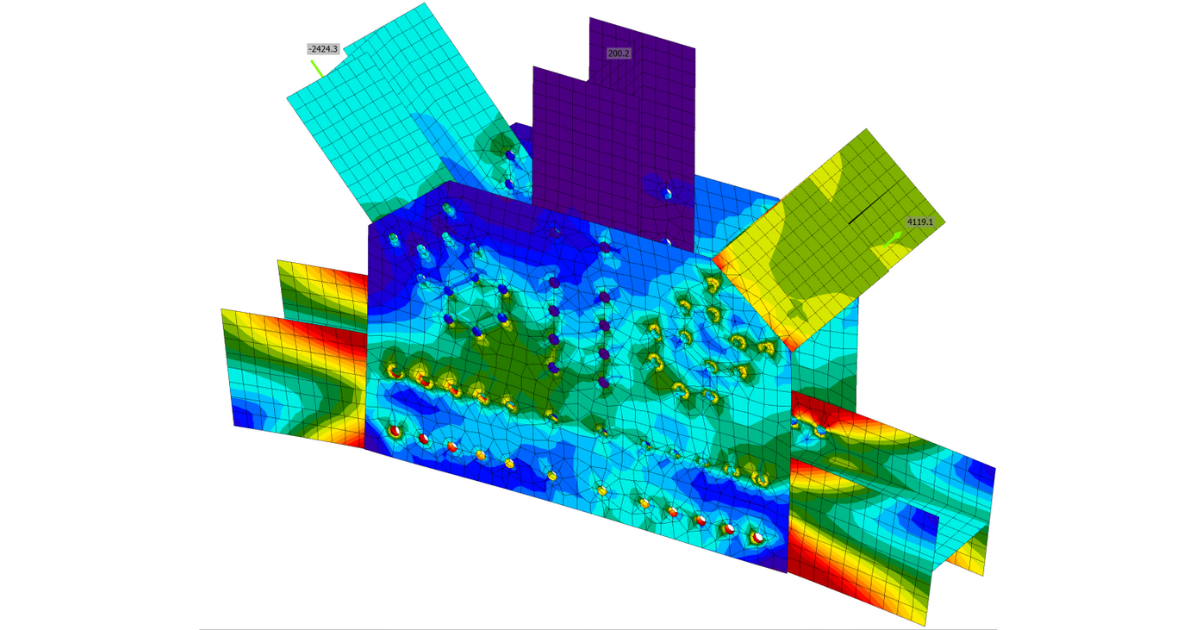

Another challenge was the complexity of the joints, particularly the stability issues related to buckling. Conducting a buckling analysis that accounts for all load combinations across varying geometries can be a demanding task for any engineer.

Solutions and results

IDEA StatiCa Connection was used specifically to solve the problems that needed to be addressed during the project.

The tool was a great benefit precisely because of the quick calculation in IDEA StatiCa Connection, the ability to verify many combinations simultaneously, and the simple iterative process that allowed repeating the procedure multiple times. Additionally, the results are highly accurate and presented in a format that is easy for everyone to understand.

Guatemala

Thanks to CBFEM, the engineers could utilize more advanced analysis and verify whether the gusset plates were not experiencing buckling. This allowed them to ensure that our design was safe, especially for a structure of such high significance and in challenging conditions. Lastly, the ability to create simple drawings and use cloud-based solutions made it easy to share the design with manufacturers, ensuring everything was clearly understood and preventing errors during production.

Take the latest IDEA StatiCa for a test drive today