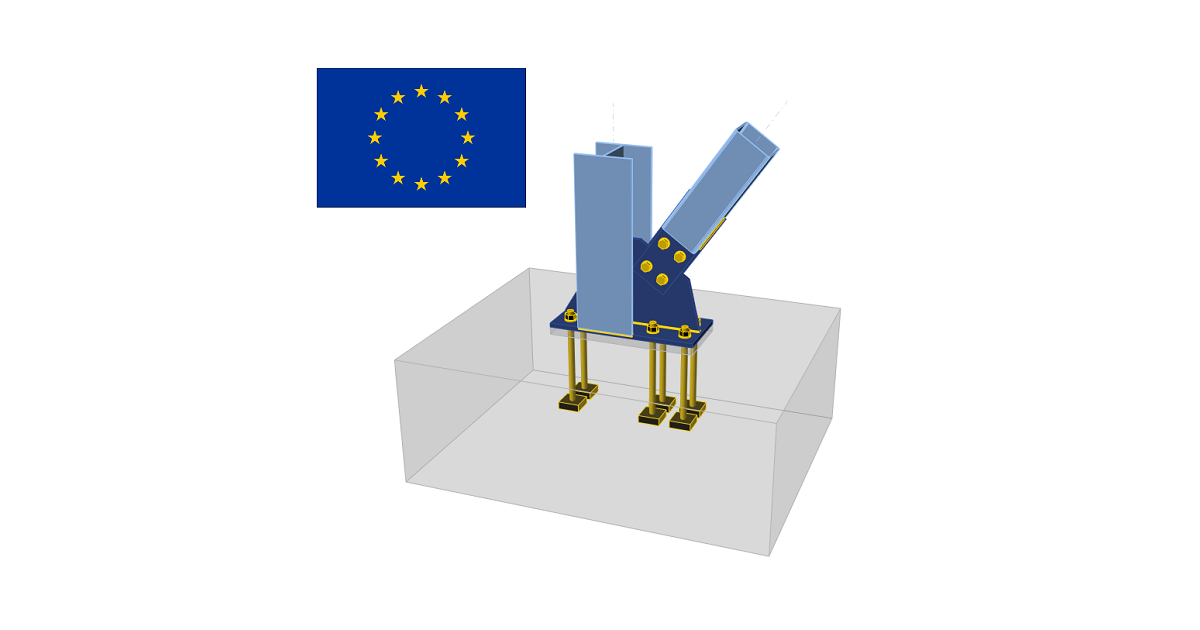

Check of steel connection components (EN)

CBFEM method combines advantages of the general Finite Element Method (FEM) and standard Component Method (CM). The stresses and internal forces calculated on the accurate CBFEM model are used in checks of all components.

Individual components are checked according to Eurocode EN 1993-1-8.

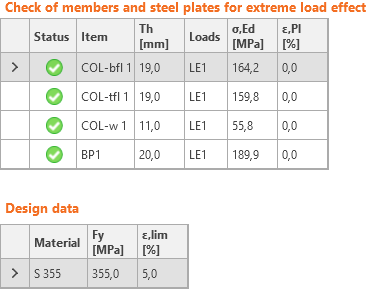

Verifica delle piastre secondo codice EN (Eurocodice)

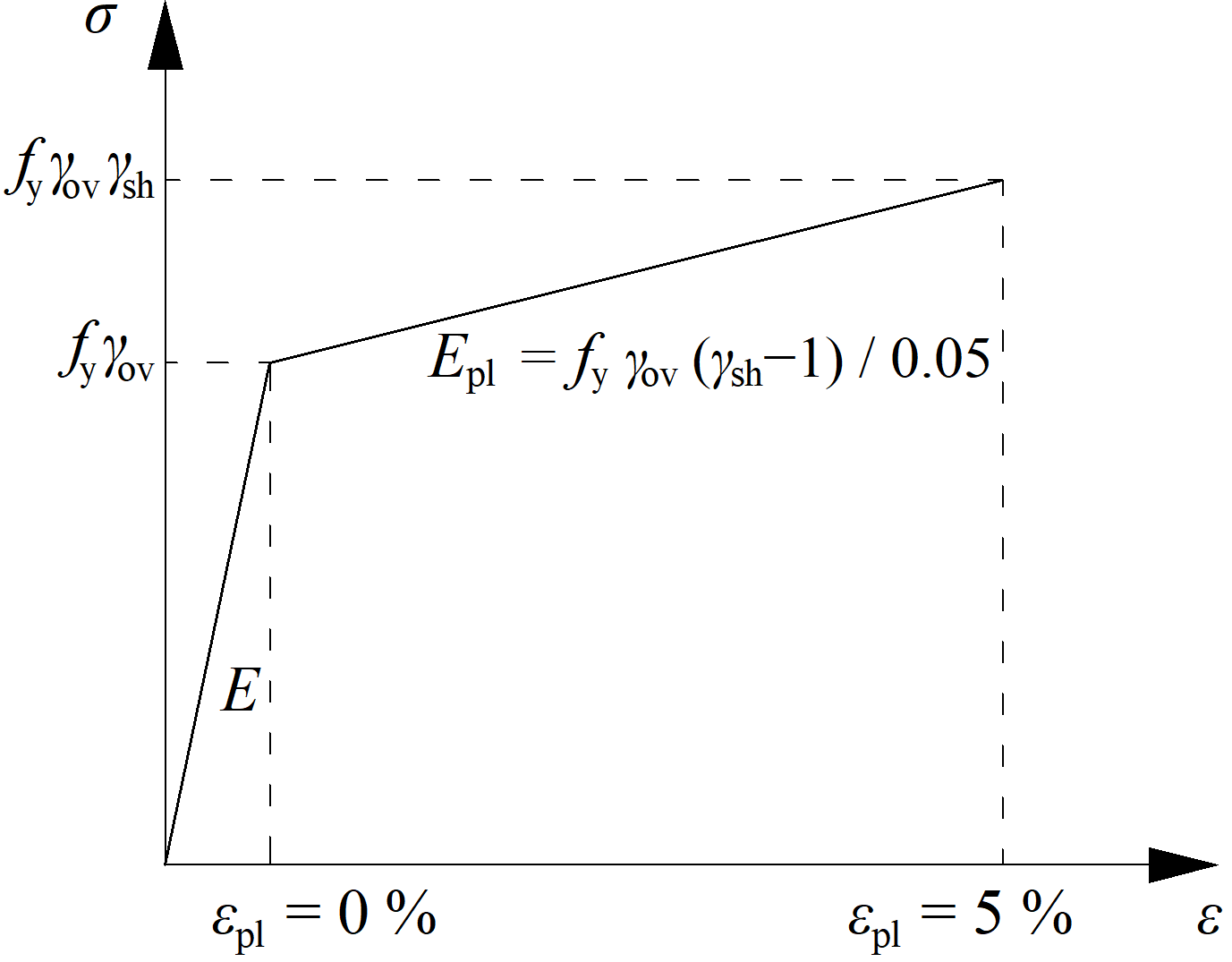

Le sollecitazioni equivalenti (Huber-Mises-Hencky - HMH, von Mises) e le deformazioni plastiche risultanti sono calcolate sulle piastre. Per le piastre in acciaio si utilizza il modello elasto-plastico del materiale. Viene eseguita una verifica della deformazione plastica equivalente. Il valore limite del 5% è suggerito dall'Eurocodice (EN 1993-1-5, app. C, par. C8, nota 1); questo valore può essere modificato dall'utente nella configurazione del Codice.

L'elemento piastra è diviso lungo il suo spessore in cinque strati di elementi finiti shells e il comportamento elastico/plastico è studiato in ogni strato separatamente. Il riassunto dell'output della verifica mostra la verifica più critica di tutti e cinque gli strati.

Il metodo CBFEM può fornire tensioni superiori al limite di snervamento. Il motivo è la leggera inclinazione del ramo plastico del diagramma sforzo-deformazione, utilizzato nell'analisi per migliorare la stabilità del calcolo dell'interazione. Questo non è un problema per la progettazione pratica. A carichi più elevati, la deformazione plastica equivalente aumenta e il giunto cede superando il limite di deformazione plastica.

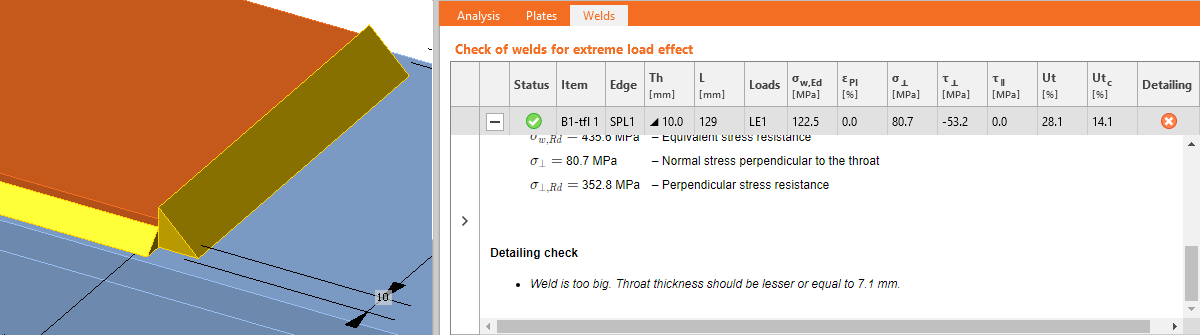

Verifiche delle saldature secondo codice (EN)

Le saldature a cordoni d'angolo sono verificate in base all'EN 1993-1-8. La resistenza delle saldature di testa si presume uguale a quella del metallo di base e non viene verificata.

Saldature ad angolo

Saldature a cordoni d'angolo

Resistenza di progetto

La ridistribuzione plastica nelle saldature è utilizzata per evitare automaticamente le singolarità di sollecitazione negli elementi di saldatura e ridistribuire le sollecitazioni lungo la lunghezza della saldatura. La resistenza della saldatura corrisponde approssimativamente al calcolo manuale e le sollecitazioni sono distribuite correttamente per questioni complesse come la saldatura su una flangia non rigida (EN 1993-1-8 - Cl. 4.10). La sollecitazione nella sezione di gola di una saldatura ad angolo è determinata in conformità alla norma EN 1993-1-8 Cl. 4.5.3. Le sollecitazioni sono calcolate a partire dalle sollecitazioni nell'elemento di saldatura. Il momento flettente attorno all'asse longitudinale della saldatura non è considerato.

\[ \sigma_{w,Ed}=\sqrt{\sigma_{\perp}^2 + 3 \left ( \tau_{\perp}^2 + \tau_{\parallel}^2 \right )} \]

\[ \sigma_{w,Rd} = \frac{f_u}{\beta_w \gamma_{M2}} \]

Utilizzo delle saldature

\[ U_t = \min \left\{ \frac{\sigma_{{w,Ed}}}{\sigma_{w,Rd}}, \frac{\sigma_{\perp}}{0.9 f_u / {\gamma_{M2}}} \right\} \]

dove:

- σw,Ed – sollecitazione equivalente nella saldatura

- σw,Rd – resistenza di saldatura

- βw – fattore di correlazione (EN 1993-1-8 - Tabella 4.1)

- fu – resistenza ultima, scelta come la più bassa tra i due materiali di base collegati o secondo il materiale scelto dall'utente

- γM2 – fattore di sicurezza (EN 1993-1-8 - Tabella 2.1; editabile in Impostazione codice)

- σ┴, τ┴, τ‖ – sollecitazioni nella weld secondo la seguente figura:

Tutti i valori richiesti per la verifica sono indicati nelle tabelle. Ut è l'utilizzo dell'elemento più sollecitato. L'utilizzo della ridistribuzione plastica delle sollecitazioni nella saldatura è decisivo. Utc fornisce informazioni sull'utilizzo lungo la lunghezza della saldatura. È il rapporto tra la sollecitazione effettiva in tutti gli elementi della saldatura e la resistenza di progetto della sollecitazione dell'intera lunghezza della saldatura.

La tensione equivalente nel diagramma di saldatura mostra la seguente sollecitazione:

\[ \sigma = \max \left \{ \frac{\sigma_{\perp}}{0.9 \beta_w}, \, \sqrt{\sigma_{\perp}^2 + 3 \tau_{\perp}^2 + 3 \tau_{\parallel}^2} \right \} \]

Saldature di testa

Le saldature possono essere specificate come saldature di testa. La penetrazione completa del giunto è considerata per le saldature di testa e pertanto tali saldature non vengono verificate.

Dettagli

Lo spessore minimo delle piastre delle connessioni saldate è verificato in conformità alla norma EN 1993-1-8 - 4.1(1):

- Per le sezioni cave di acciaio, lo spessore della piastra deve essere di almeno 2.5 mm

- Per le altre piastre, lo spessore della piastra deve essere di almeno 4 mm

Lo spessore massimo della gola della saldatura delle saldature d'angolo viene controllato per piastre parallele. Viene emesso un errore, tale saldatura non è fattibile a causa di vincoli geometrici.

Lo spessore minimo della gola delle saldature d'angolo deve essere di almeno 3 mm secondo EN 1993-1-8 – 4.5.2(2). Viene emesso un errore quando questo requisito non è soddisfatto.

Viene emesso un avvertimento quando lo spessore della gola di saldatura è inferiore ai requisiti della norma DIN EN 1993-1-8 – NA fino a 4.5.2:

\[a \le \sqrt{t_{max}}-0.5\]

dove:

- \(a\) – altezza di gola della saldatura

- \(t_{max}\) – spessore della piastra collegata più spessa

- le unità di misura devono essere in [mm]

Le informazioni sono fornite quando l'altezza di gola della saldatura è inferiore rispetto al requisito di duttilità minima dei giunti saldati ai sensi del FprEN 1993-1-8:2023 - 6.9(4). Tale requisito è verificato per le saldature ad angolo bilaterali da:

\[a/t=\frac{\beta_w\gamma_{M2} f_y}{\sqrt{2} f_u \gamma_{M0} } \cdot \min \left \{1.0, 1.1\frac{f_y}{f_u} \right \}\]

dove:

- \(a\) – altezza di gola della saldatura

- \(t\) – spessore della piastra collegata lungo il bordo

- \(\beta_w\) – fattore di correlazione della saldatura

- \(\gamma_{M2}\) – fattore di sicurezza per bulloni e saldature; editabile in Impostazione codice

- \(f_y\) – resistenza limite della piastra

- \(f_u\) – resistenza ultima della saldatur

- \(\gamma_{M0}\) – fattore di sicurezza per le piastre; editabile in Impostazione codice

L'altezza di gola della saldatura ad angolo unilaterale è due volte superiore a quella della saldatura ad angolo bilaterale.

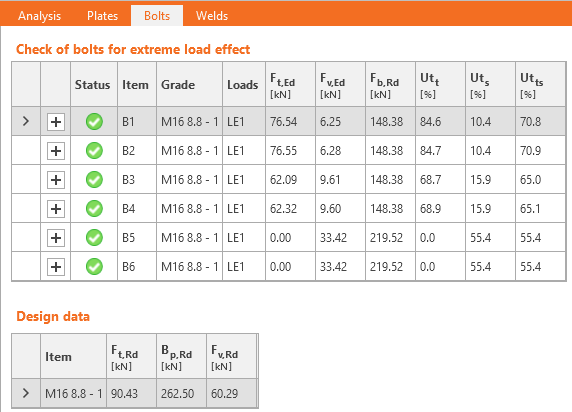

Verifica dei bulloni e dei bulloni precaricati secondo Eurocodice (EN)

Bulloni

La rigidezza iniziale e la resistenza di progetto dei bulloni a taglio sono indicate nel CBFEM redatto sulla base del Cl. 3.6 e 6.3.2 nella norma EN 1993-1-8. La molla, che rappresenta il carico e la trazione, ha un comportamento forza-deformazione bi-lineare con una rigidezza iniziale e una resistenza di progetto in accordo alla Cl. 3.6 e 6.3.2 nella norma EN 1993-1-8.

Resistenza di progetto del bullone a trazione (EN 1993-1-8 - Tabella 3.4):

\[ F_{t,Rd}=0.9 f_{ub} A_s / \gamma_{M2} \]

Resistenza di progetto a taglio mediante punzonamento della testa del bullone o del dado (EN 1993-1-8 - Tabella 3.4):

\[ B_{p,Rd} = 0.6 \pi d_m t_p f_u / \gamma_{M2} \]

Resistenza di progetto a taglio per un piano di taglio (EN 1993-1-8 - Tabella 3.4):

\[ F_{v,Rd} = \alpha_v f_{ub} A_s / \gamma_{M2} \]

La resistenza di progetto a taglio può essere moltiplicata per il fattore di riduzione βp se è presente un'imbottitura (EN 1993-1-8 - Cl.). 3.6.1. (12)) e questa opzione è selezionata in Impostazione codice.

Resistenza di progetto a rifollamento di una piastra (EN 1993-1-8 - Tabella 3.4):

\( F_{b,Rd} = k_1 \alpha_b f_u d t / \gamma_{M2} \) per fori standard

\( F_{b,Rd} = 0.6 k_1 \alpha_b f_u d t / \gamma_{M2} \) per fori asolati

Utilizzo in trazione [%]:

\[ Ut_t = \frac{F_{t,Ed}}{\min (F_{t,Rd},\, B_{p,Rd})} \]

Utilizzo a taglio [%]:

\[ Ut_s = \frac{F_{v,Ed}}{\min (F_{v,Rd},\, F_{b,Rd})} \]

Interazione al taglio e trazione [%]:

\[ Ut_{ts}=\frac{F_{v,Ed}}{F_{v,Rd}}+\frac{F_{t,Ed}}{1.4 F_{t,Rd}} \]

dove:

- As – area del bullone sollecitata a trazione

- fub – resistenza ultima del bullone a trazione

- dm – media delle distanze piane tra i punti e le larghezze della testa del bullone o del dado, a seconda della più piccola

- d – diametro del bullone

- tp – spessore della piastra sotto la testa del bullone/dado

- fu – resistenza ultima dell'acciaio

- αv = 0.6 per classi 4.6, 5.6, 8.8 e 0.5 per classi 4.8, 5.8, 6.8, 10.9

- \( k_1 = \min \left \{2.8 \frac{e_2}{d_0}-1.7, \, 1.4 \frac{p_2}{d_0}-1.7, \, 2.5 \right \} \) – coefficiente indicato nella Tabella 3.4

- \(\alpha_b = 1.0\) se la verifica in bearing con \(\alpha_b\) è disattivata in Impostazione codice; se la verifica è attiva, il valore di αb è determinato secondo la EN 1993-1-8 – Tabella 3.4: \( \alpha_b = \min \left \{ \alpha_d, \, \frac{f_{ub}}{f_u}, \, 1.0 \right \} \)

- \(\alpha_d = \min \left \{ \frac{e_1}{3 d_0}, \, \frac{p_1}{3 d_0}-\frac{1}{4} \right \} \)

- e1, e2 – distanze dal bordo nella direzione del carico e perpendicolari al carico

- p1, p2 – passi dei bulloni nella direzione del carico e perpendicolari al carico

- Ft,Ed – forza di progetto a trazione nel bullone

- Fv,Ed – forza di taglio di progetto nel bullone

- γM2 – coefficiente di sicurezza (EN 1993-1-8 – Tabella 2.1; modificabile in Impostazione codice)

Le distanze dai bordi utilizzate per la resistenza (bearing resistance) dei bulloni devono essere rilevante per le geometrie generali delle piastre, per le piastre con aperture, per le sagome, ecc.

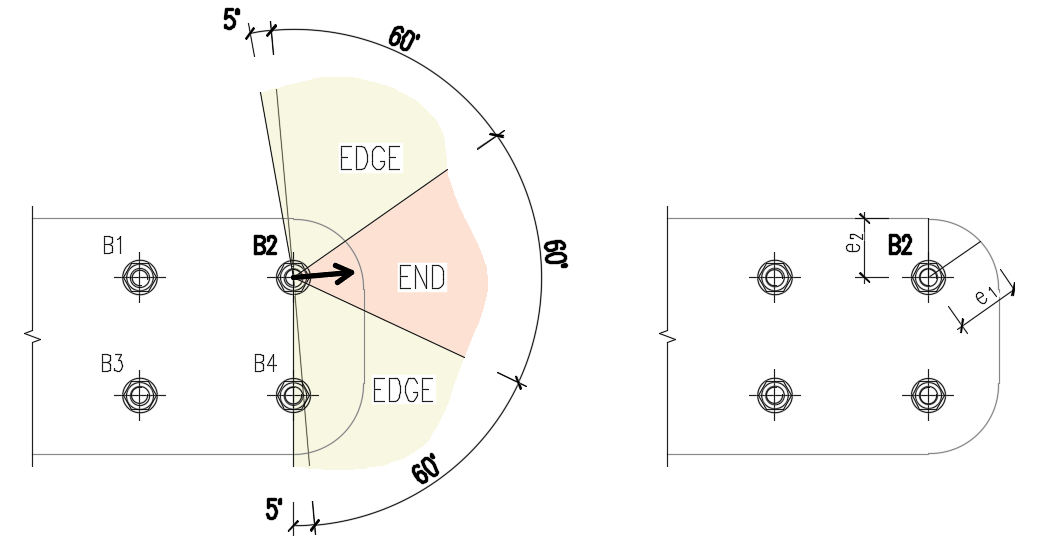

L'algoritmo legge la direzione reale del vettore della forza di taglio risultante in un dato bullone e, successivamente, calcola le distanze necessarie per la verifica (bearing check).

Le distanze dall'estremità (e1) e dal bordo (e2) sono determinate dividendo il contorno della piastra in tre segmenti. Il segmento di estremità è indicato da un angolo di 60° nella direzione del vettore della forza. I segmenti di bordo sono definiti da due angoli di 65° perpendicolari al vettore di forza. La distanza più breve tra un bullone e un segmento rilevante è considerata, quindi, come una distanza di estremità o di bordo.

Le distanze tra i fori dei bulloni (p1; p2) sono determinate allargando virtualmente i fori dei bulloni circostanti per metà del loro diametro e, successivamente, tracciando due linee, una parallela e una perpendicolare, al vettore della forza di taglio. Le distanze dai fori dei bulloni allargati che sono intersecati da queste linee sono quindi considerate nel calcolo come p1 e p2.

Bulloni che collegano piastre sottili

Per i bulloni che collegano piastre di spessore inferiore a 3 mm, si applicano invece le disposizioni della norma EN 1993-1-3, Tabella 8.4.

Resistenza di progetto a rifollamento della piastra

\[F_{b,Rd}=2.5\cdot \alpha_b \cdot k_t \cdot f_u \cdot d \cdot t /\gamma_{M2}\]

dove:

- \( \alpha_b=\min \left \{ 1.0, e_1/(3d) \right \} \)

- \(k_t = (0.8 t+1.5)/2.5 \) for 0.75 mm \(\le t \le\) 1.25 mm; \( k_t=1.0 \) for \(t>1.25\) mm

- \(f_u\) – resistenza ultima della piastra collegata

- \(d\) – diametro del bullone

- \(t\) – spessore della piastra collegata

- \(\gamma_{M2}\) – coefficiente di sicurezza parziale per i collegamenti, editabile in Impostazione codice; valore predefinito \(\gamma_{M2}=1.25\)

La resistenza a taglio, la resistenza a trazione, l'interazione di trazione e di taglio e la resistenza a taglio mediante rifollamento sono determinate in base alla norma EN 1993-1-8 - ugualmente ai bulloni che collegano piastre con uno spessore superiore a 3 mm.

Intervallo di validità:

\[e_1 \ge 1.0 d_0 \]

\[p_1 \ge 3 d_0 \]

\[e_2 \ge 1.5 d_0 \]

\[p_2 \ge 3 d_0 \]

\[ f_u \le 550 \textrm{ MPa} \]

\[3 \textrm{ mm} > t \ge 0.75 \textrm{ mm} \]

Dimensione minima dei bulloni: M6 – verificata come \(d \ge 6\) mm

Classe di resistenza dei bulloni: 4.6 – 10.9 – verificata come \(f_u \le 1000\) MPa

I bulloni saranno contrassegnati come non verificati se non rientreranno nell'intervallo di validità.

Bulloni precaricati

Resistenza di progetto a scorrimento per bulloni di classe 8.8 o 10.9 (EN 1993-1-8, Cl. 3.9 - Equazione 3.8):

\[ F_{s,Rd} =\frac{k_s n \mu (F_{p,C} - 0.8 F_{t,Ed})}{\gamma_{M3}} \]

Il precarico (EN 1993-1-8 – Equazione 3.7)

Fp,C = 0.7 fub As

Il fattore di precarico 0,7 può essere modificato in Impostazione codice.

Utilizzo [%]:

\[ Ut_s = \frac{V}{F_{s,Rd}} \]

dove:

- As – area del bullone sollecitata a trazione

- fub – resistenza ultima a trazione

- ks – coefficiente (EN 1993-1-8 – Tabella 3.6; ks = 1 per i fori tondi normali, ks = 0.63 per i fori asolati)

- μ – coefficiente di scorrimento modificabile in Impostazione codice (EN 1993-1-8 – Tabella 3.7)

- n – numero delle superfici di attrito. La verifica è calcolata separatamente per ogni superficie di attrito.

- γM3 – coefficiente di sicurezza (EN 1993-1-8 - Tabella 2.1; editabile in Impostazione codice - i valori raccomandati di progetto sono 1,25 per lo stato limite ultimo e 1,1 per lo stato limite di esercizio)

- V – forza di taglio di progetto nel bullone

- Ft,Ed – forza di trazione di progetto nel bullone

Se lo scorrimento dei bulloni precaricati viene verificato per lo stato limite di esercizio, questi devono essere successivamente commutati in "interazione trazione/taglio" e verificati per lo stato limite ultimo.

Resistenza di progetto al fuoco

Si presume che i bulloni precaricati slittino, per cui le verifiche dei bulloni portanti e dei bulloni precaricati sono le stesse.

Sono eseguite sia verifiche al fuoco sia a temperatura ambiente e il valore minimo viene scelto come resistenza al carico di progetto.

A temperatura elevata, i bulloni sono verificati secondo la norma EN 1993-1-2, Allegato D. Si noti che l'area ridotta dalla filettatura è sempre utilizzata per la verifica a taglio secondo il punto D1.1.1.

Dettagli

Le verifiche dei dettagli dei bulloni sono eseguiti se l'opzione è selezionata in impostazione codice. Sono verificate le distanze dal centro del bullone ai bordi della piastra e tra i bulloni. Le distanze raccomandate dai bordi e = 1,2 e tra i bulloni p = 2,2 sono indicate nella Tabella 3.3 secondo la norma EN 1993-1-8. L'utente può modificare entrambi i valori in Impostazione codice.

È controllato lo spessore minimo delle piastre collegate da bulloni. Lo spessore delle piastre deve essere superiore a 0,75 mm in conformità alla norma EN 1993-1-3 - Tabella 8.4.

Le informazioni sono fornite quando i requisiti di duttilità e di capacità di rotazione per il collegamento bullonato in trazione non sono soddisfatti, in conformità alla norma EN 1993-1-8 - 6.4.2. Se il bullone è caricato prevalentemente in trazione, la piastra collegata più sottile dovrebbe soddisfare tali requisiti:

\[t \le 0,36d \sqrt{\frac{f_{ub}}{f_y}}\]

Le dimensioni predefinite dei gruppi di bulloni sono stabilite in conformità alle norme EN ISO 4014 - Teste di bulloni esagonali; EN ISO 4032 - Dadi esagonali regolari; EN ISO 7089 - Rondelle piane - Serie normale - Grado prodotto A.

Code-check of anchors (EN)

Four anchor bolt types are available:

- Straight (assumed post-installed)

- Washer plate - Circular (assumed cast-in)

- Washer plate - Rectangle (assumed cast-in)

- Hook (assumed cast-in)

The steel resistances are determined according to EN 1993-1-8 and EN 1992-4 for cast-in anchors and post-installed fasteners, respectively.

The concrete resistances are determined according to EN 1992-4.

In case of post-installed (straight) fasteners, pull-out failure, combined pull-out and concrete failure of bonded anchors, and concrete splitting failure are not checked due to missing information available only for the particular anchor and glue type from the anchor manufacturer.

In the Project settings, settings are available to activate/deactivate concrete cone breakout checks in tension and shear. If the concrete cone breakout check is not activated, it is assumed that the dedicated reinforcement is designed to resist the force. The magnitude of the force is provided in formulas. User may use link to Detail application to perform the checks of reinforced concrete.

Furthermore, the concrete can be set as cracked or uncracked. Uncracked concrete should be in permanent compression that prevents shrinkage cracks. The resistances of uncracked concrete are higher.

Tensile steel resistance (EN 1993-1-8, Table 3.4)

Cast-in anchors are checked according to steel design code.

\[ F_{t,Rd} = \frac{c \cdot k_2 \cdot f_{ub} \cdot A_s}{\gamma_{M2}} \]

where:

- c – decrease in tensile resistance of bolts with cut thread according to EN 1993-1-8 – Cl. 3.6.1. (3) editable in Project Settings

- k2 = 0.9 – factor for non-countersunk anchors

- fub – anchor bolt ultimate tensile strength

- As – anchor bolt tensile stress area

- \(\gamma_{M2}=1.25\) – partial safety factor for bolts (EN 1993-1-8, Table 2.1) editable in Project Settings

Tensile steel resistance (EN 1992-4, Cl. 7.2.1.3)

Post-installed fasteners are checked according to concrete design code

\[ N_{Rd,s} = \frac{N_{Rk,s}}{\gamma_{Ms}} \]

where:

- NRk,s = c ∙ As ∙ fuk – characteristic resistance of a fastener in case of steel failure

- c – decrease in tensile resistance of bolts with cut thread according to EN 1993-1-8 – Cl. 3.6.1. (3) editable in Code setup

- As – anchor bolt tensile stress area

- fuk – anchor bolt characteristic ultimate tensile strength

- \(\gamma_{Ms}=1.2 \cdot \frac{f_{uk}}{f_{yk}} \ge 1.4\) – partial safety factor for steel failure in tension (EN 1992-4, Table 4.1)

- fyk – anchor bolt characteristic yield strength

Concrete cone failure resistance of anchor or group of anchors (EN 1992-4, Cl. 7.2.1.4):

\[ N_{Rd,c} = \frac{N_{Rk,c}}{\gamma_{Mc}} \]

where:

- \(N_{Rk,c}=N_{Rk,c}^0 \cdot \frac{A_{c,N}}{A_{c,N}^0} \cdot \psi_{s,N} \cdot \psi_{re,N} \cdot \psi_{ec,N} \cdot \psi_{M,N}\) – characteristic resistance of a fastener, a group of fasteners and the tensioned fasteners of a group of fasteners in case of concrete cone failure

- \(N_{Rk,c}^0 = k_1 \sqrt{f_{ck}} h_{ef}^{1.5}\) – characteristic resistance of a single fastener placed in concrete and not influenced by adjacent fasteners or edges of the concrete member

- k1 – factor taking into account concrete condition and anchor type; for cast-in headed anchors (with washer plates) k1 = 8.9 for cracked concrete and k1 = 12.7 for non-cracked concrete; for post-installed fasteners (straight anchors) k1 = 7.7 for cracked concrete and k1 = 11.0 for non-cracked concrete

- fck – characteristic concrete compressive cylinder strength

- hef – embedment depth of the anchor in concrete; for three or more close edges, EN 1992-4, Cl. 7.2.1.4 (8) applies and effective \(h'_{ef} = \max \left \{ \frac{c_{max}}{c_{cr,N}} \cdot h_{ef}, \, \frac{s_{max}}{s_{cr,N}} \cdot h_{ef} \right \}\) is used instead in formulas for NRk,c0, ccr,N, scr,N, Ac,N, Ac,N0, ψs,N, and ψec,N

- Ac,N – actual projected area, limited by overlapping concrete cones of adjacent fasteners as well as by edges of the concrete member

- Ac,N0 = scr,N2 – reference projected area, i.e. area of concrete of an individual anchor with large spacing and edge distance at the concrete surface

- \(\psi_{s,N}=0.7+0.3 \cdot \frac{c}{c_{cr,N}} \le 1\) – factor taking into account disturbance of the distribution of stresses in the concrete due to the proximity of an edge of the concrete member

- c – smallest edge distance

- ccr,N = 1.5 ∙ hef – characteristic edge distance for ensuring the transmission of the characteristic resistance of an anchor in case of concrete break-out under tension loading

- \(\psi_{re,N}=0.5+\frac{h_{ef}}{200} \le 1\) – shell spalling factor

- \(\psi_{ec,N}=\frac{1}{1+2 \cdot (e_N / s_{cr,N})} \le 1\) – factor taking into account group effect when different tension loads are acting on the individual fasteners of a group; ψec,N is determined separately for each direction and the product of both factors is used

- eN – eccentricity of resultant tension force of tensioned fasteners in respect to the center of gravity of the tensioned fasteners

- scr,N = 2 ∙ ccr,N – characteristic spacing of anchors to ensure the characteristic resistance of the anchors in case of concrete cone failure under tension load

- \(\psi_{M,N} = 2- \frac{z}{1.5 \cdot h_{ef}} \ge 1\) – factor taking into account effect of a compression force between fixture and concrete in cases of bending moments with or without axial force; this parameter is equal to 1 if c < 1.5 hef or the ratio of the compressive force (including the compression due to bending) to the sum of tensile forces in anchors is smaller than 0.8 or z / hef ≥ 1.5

- z – internal lever arm of a fastening

- γMc = γc ∙ γinst – partial safety factor (EN 1992-4, Table 4.1)

- γc – partial safety factor for concrete (editable in Code setup)

- γinst – partial safety factor taking account of the installation safety of an anchor system (editable in Code setup)

The concrete breakout cone area for a group of anchors loaded by tension that creates a common concrete cone, Ac,N, is shown by the red dashed line.

Pull-out resistance (EN 1992-4, Cl. 7.2.1.5)

Pull-out resistance is checked for cast-in anchors with washer plates according to EN 1992-4, Cl. 7.2.1.5:

\[ N_{Rd,p}=\frac{N_{Rk,p}}{\gamma_{Mc}} \]

where:

- NRk,p = k2 ∙ Ah ∙ fck – characteristic resistance in case of pull-out failure

- k2 – coefficient dependent on concrete condition, k2 = 7.5 for cracked concrete, k2 = 10.5 for non-cracked concrete

- Ah – bearing area of head of anchor; for circular washer plate \(A_h = \frac{\pi}{4} \left ( d_h^2 - d^2 \right )\), for rectangular washer plate \(A_h = a_{wp}^2 - \frac{\pi}{4} d^2\)

- dh ≤ 6 th + d – diameter of the head of the fastener

- th – thickness of the head of the headed fastener

- d – diameter of the shank of the fastener

- fck – characteristic concrete compressive cylinder strength

- γMc = γc ∙ γinst – partial safety factor (EN 1992-4, Table 4.1)

- γc – partial safety factor for concrete (editable in Code setup)

- γinst – partial safety factor taking account of the installation safety of an anchor system (editable in Code setup)

Pull-out resistance (EN 1992-1-1, Cl. 8.4.4)

Pull-out resistance is checked for cast-in anchors with hook according to EN 1992-1-1, Cl. 8.4.4. Plain rods are assumed that require double anchorage length than ribbed reinforcement (Table 3.26 in BS 8110-1).

\[N_{Rd,p}=A_a \cdot f_{ya} \cdot \frac{l_b}{l_{bd}}\]

where:

- Aa – tensile stress area of an anchor

- fya – anchor yield strength

- lb – anchor length embedded in concrete

- \(l_{bd} = \alpha_1 \cdot \alpha_2 \cdot \alpha_3 \cdot \alpha_4 \cdot \alpha_5 \cdot l_{b,rqd}\) – design anchorage length

- \(\alpha_1\) – factor for the effect of the shape of the bars assuming adequate cover

- \(\alpha_1 = 0.7\) for \(c_d > 3 \phi\)

- \(\alpha_1 = 1.0\) for \(c_d \le 3 \phi\)

- \(c_d = \min \{a/2, c_1\}\) – adequate cover

- a – clear distance between anchors

- c1 – clear distance to concrete block edge

- \(\phi\) – anchor diameter

- \(\alpha_2 = 1.0 - 0.15 \frac{c_d - \phi}{\phi}\) – factor for the effect of concrete minimum cover; \(0.7 \le \alpha_2 \le 1.0\)

- \(\alpha_3 = 1.0\) – factor for the effect of confinement by transverse reinforcement

- \(\alpha_4 = 1.0 \) – factor for the influence of one or more welded transverse bars along the design anchorage length

- \(\alpha_5=1.0\) – factor for the effect of the pressure transverse to the plane of splitting along the design anchorage length

- \(l_{b,rqd} = \frac{\phi}{4} \frac{f_{ya}}{f_{bd}}\) – required anchorage length

- \(f_{bd} = \frac{2.25 \cdot \eta_1 \cdot \eta_2 f_{ctd}}{2}\) – design value of the ultimate bond stress (assumed half that of ribbed reinforcement)

- \(\eta_1=1.0\) – coefficient related to the quality of the bond condition and the position of the bar during concreting; good conditions are assumed, which may be dangerous for the rare case of horizontal anchors placed at the top of the concrete

- \(\eta_2=\min \{1.0, \frac{132-\phi}{100}\) – coefficient related to the bar diameter

- \(f_{ctd}=\frac{\alpha_{ct} \cdot f_{ctk,0.05}}{\gamma_c}\) – design value of concrete tensile strength

- \(\alpha_{ct}=1.0\) – coefficient taking account of long term effects on the tensile strength and of unfavourable effects

- \(f_{ctk,0.05}\) – characteristic axial tensile strength of concrete (5% quantile)

- \(\gamma_c\) – safety factor for concrete editable in Project Settings

Several detailing rules are added:

- Anchor yield strength must not be higher than 300 MPa (EN 1993-1-8 – 6.2.6.12 (5))

- Minimum anchorage length \(l_{b,min}\) must be kept (EN 1992-1-1 – Equation (8.6)):

\[ l_b \ge l_{b,min} = \max \{ 0.3 \cdot l_{b,rqd}, 10\cdot \phi , 100 \}\]

- Anchorage length should be sufficient for the steel tensile failure mode to govern to facilitate plastic design

The pullout resistance of other types of anchors is not checked and must be guaranteed by the manufacturer.

Concrete blowout resistance (EN 1992-4, Cl. 7.2.1.8)

Blow-out failure is checked for cast-in headed anchors (Anchor type – washer) with edge distance c ≤ 0.5 hef according to EN 1992-4, Cl. 7.2.1.8. Anchors are treated as a group if their spacing near the edge is s ≤ 4 c1. Undercut anchors can be checked the same way but the value of Ah is unknown in the software. The blow-out failure of undercut anchors can be determined by selecting a washer plate with the corresponding dimension.

\[N_{Rd,cb} = \frac{N_{Rk,cb}}{\gamma_{Mc}}\]

where:

- \(N_{Rk,cb} = N_{Rk,cb}^0 \cdot \frac{A_{c,Nb}}{A_{c,Nb}^0} \cdot \psi_{s,Nb} \cdot \psi_{g,Nb} \cdot \psi_{ec,Nb}\) – characteristic resistance in case of concrete blow-out failure

- \(N_{Rk,cb}^0 = k_5 \cdot c_1 \cdot \sqrt{A_h} \cdot \sqrt{f_{ck}}\) – characteristic resistance of a single fastener, not influenced by adjacent fasteners or further edges

- Ac,Nb – actual projected area, limited by overlapping concrete break-out bodies of adjacent fasteners as well as by proximity of edges of the concrete member or the member thickness

- Ac,Nb0 = (4 c1)2 – reference projected area of a single fastener with an edge distance equal to c1

- \(\psi_{s,Nb} = 0.7+0.3 \frac{c_2}{2 c_1} \le 1\) – factor taking into account the disturbance of the distribution of stresses in the concrete due to the proximity of a corner of the concrete member

- \( \psi_{g,Nb} = \sqrt{n} + (1-\sqrt{n}) \frac{s_2}{4c_1} \ge 1 \) – factor taking into account group effect

- \(\psi_{ec,Nb} = \frac{1}{1+2 e_N / s_{cr,Nb}} \le 1\) – factor taking into account group effect, when different loads are acting on the individual fasteners of a group

- k5 – parameter related to the state of the concrete; for cracked concrete k5 = 8.7, for uncracked concrete k5 = 12.2

- c1 – edge distance of fastener in direction 1 towards the closest edge

- c2 – edge distance of fastener perpendicular to direction 1 that is the smallest edge distance in a narrow member with multiple edge distances

- Ah – area of the load-bearing head of the fastener; for circular washer plate \(A_h = \frac{\pi}{4} \left ( d_h^2 - d^2 \right )\), for rectangular washer plate \(A_h = a_{wp}^2 - \frac{\pi}{4} d^2\)

- d – anchor nominal diameter

- dh – circular washer plate diameter

- awp – side size of squared washer plate

- fck – characteristic compressive cylinder strength of concrete

- n – number of fasteners in a row parallel to the edge of the concrete member

- s2 – spacing of fasteners in a group perpendicular to direction 1

- scr,Nb = 4 c1 – spacing that is required for a fastener to develop its characteristic tensile strength against blow-out failure

Anchor shear steel resistance (EN 1993-1-8 – Cl. 6.2.2)

Anchor shear steel resistance of cast-in anchors is determined according to EN 1993-1-8 – 6.2.2 (7) regardless of direct or mortar joint stand-off. The addition of friction is problematic in practice and is not assumed. The background for Eurocode calculation is the Stevin Laboratory model presented in this paper. Holes should be standard, not oversized and the grout strength and thickness should be according to Cl. 6.2.5 (7).

\[F_{vb,Rd} = \min \{F_{1vb,Rd}, F_{2vb,Rd} \} \]

where:

- \(F_{1vb,Rd} = \frac{\alpha_v \cdot f_{ub} \cdot A}{\gamma_{M2}}\) – anchor shear resistance from Table 3.4

- αv = 0.6 for grades 4.6, 5.6, 8.8 and 0.5 for grades 4.8, 5.8, 6.8, 10.9

- fub – ultimate tensile strength of the bolt

- A – tensile stress area of the bolt

- A = A for shear plane excluded from threads; A is gross cross-section area of the anchor

- A = As for shear plane intercepted by threads; As is tensile stress area of the bolt

- γM2 – safety factor (EN 1993-1-8 – Table 2.1; editable in Project Settings)

- \(F_{2vb,Rd} = \frac{\alpha_b \cdot f_{ub} \cdot A_s}{\gamma_{M2}}\) – anchor shear resistance from Equation (6.2)

- \(\alpha_b = 0.44 - 0.0003 f_{yb}\) – coefficient depending on the yield strength the anchor bolt

- fyb – anchor yield strength; 235 MPa \(\le f_{yb} \le\) 640 MPa

- fub – anchor tensile strength

- As – tensile stress area

Anchor shear steel resistance (EN 1992-4 – Cl. 7.2.2.3)

Anchor shear steel resistance of post-installed fasteners is checked according to EN 1992-4 – Cl. 7.2.2.3. Friction is not taken into account. Shear with and without lever arm is recognized in dependence on base plate manufacturing operation settings.

\[V_{Rd,s} = \frac{V_{Rk,s}}{\gamma_{Ms}}\]

For stand-off: direct, the shear without lever arm is assumed (EN 1992-4 – Cl. 7.2.2.3.1):

VRk,s = k6 ∙ As ∙ fuk – characteristic resistance of a single fastener in case of steel failure; or fasteners with a ratio hef / dnom < 5 and a concrete compressive strength class < C20/25 the characteristic resistance VRk,s should be multiplied by a factor of 0.8.

For stand-off: mortar joint, the shear with lever arm is assumed (EN 1992-4 – Cl. 7.2.2.3.2):

\[V_{Rk,s}= \frac{\alpha_M \cdot M_{Rk,s}}{l_a}\]

where:

- k6 = 0.6 for anchors with fuk ≤ 500 MPa; k6 = 0.5 otherwise

- As – shear area of anchor; if shear plane in a thread is selected, the area reduced by threads is used; otherwise, full shank area is used

- fuk – anchor bolt ultimate strength

- αM = 2 – full restraint is assumed (EN 1992-4 – Cl. 6.2.2.3)

- \( M_{Rk,s} = M_{Rk,s}^0 \left ( 1 - \frac{N_{Ed}}{N_{Rd,s}} \right ) \) – characteristic bending resistance of the anchor decreased by the tensile force in the anchor

- MRk,s0 = 1.2 Wel fub – characteristic bending resistance of the anchor (ETAG 001, Annex C – Equation (5.5b))

- \( W_{el} = \frac{\pi d^3}{32}\) – section modulus of the anchor

- d – anchor bolt diameter; if the shear plane in a thread is selected, the diameter reduced by threads is used; otherwise, nominal diameter, dnom, is used

- NEd – tensile force in the anchor

- NRd,s – tensile resistance of the anchor

- la = 0.5 dnom + tmortar + 0.5 tbp – lever arm

- tmortar – thickness of mortar (grout)

- tbp – thickness of the base plate

- γMs = 1.0 ∙ fuk / fyk ≥ 1.25 for fuk ≤ 800 MPa and fyk / fuk ≤ 0.8; γMs = 1.5 otherwise – partial safety factor for steel failure (EN 1992-4 – Table 4.1)

Concrete pry-out failure (EN 1992-4 – Cl. 7.2.2.4):

\[ V_{Rd,cp}= \frac{V_{Rk,cp}}{\gamma_{Mc}} \]

where:

- VRk,cp = k8 ∙ NRk,c – characteristic resistance of concrete pry-out failure

- k8 = 1 for hef < 60 mm; k8 = 2 for hef ≥ 60 mm (ETAG 001, Annex C – Cl. 5.2.3.3)

- NRk,c – characteristic resistance of a fastener, a group of fasteners, and the tensioned fasteners of a group of fasteners in case of concrete cone failure; all anchors are assumed to be in tension

- γMc = γc – partial safety factor (EN 1992-4 – Table 4.1, γinst = 1.0 for shear loading)

- γc – partial safety factor for concrete (editable in Code setup)

Concrete edge failure (EN 1992-4 – Cl. 7.2.2.5):

Concrete edge failure is a brittle failure, and the worst possible case is checked, i.e. only the anchors located near the edge transfer the full shear load acting on a whole base plate. If anchors are positioned in a rectangular pattern, the row of anchors at the investigated edge transfers the shear load. If anchors are positioned irregularly, the two anchors nearest to the investigated edge transfer the shear load. Two edges in the direction of the shear load are investigated, and the worst case is shown in the results.

Investigated edges in dependence on the direction of the shear force resultant

\[ V_{Rd,c} = \frac{V_{Rk,c}}{\gamma_{Mc}} \]

where:

- \( V_{Rk,c}= V_{Rk,c}^0 \cdot \frac{A_{c,V}}{A_{c,V}^0} \cdot \psi_{s,V} \cdot \psi_{h,V} \cdot \psi_{ec,V} \cdot \psi_{\alpha,V} \cdot \psi_{re,V} \) – characteristic resistance of a fastener or a group of fasteners loaded towards the edge

- \( V_{Rk,c}^0 = k_9 \cdot d_{nom}^\alpha \cdot l_f^\beta \cdot f_{ck}^{0.5} \cdot c_1^{1.5}\) – initial value of the characteristic resistance of a fastener loaded perpendicular to the edge

- k9 – factor taking into account concrete condition; k9 = 1.7 for cracked concrete, k9 = 2.4 for non-cracked concrete

- \( \alpha = 0.1 \left ( \frac{l_f}{c_1} \right ) ^{0.5} \)

- \( \beta = 0.1 \left ( \frac{d_{nom}}{c_1} \right ) ^{0.2} \)

- lf = min (hef, 12 dnom) for dnom ≤ 24 mm; lf = min [hef, max (8 dnom, 300 mm)] for dnom > 24 mm – effective length of the anchor in shear

- hef – embedment depth of the anchor in concrete

- c1 – distance from the anchor to the investigated edge; for fastenings in a narrow, thin member, the effective distance \( c'_1=\max \left \{ \frac{c_{2,max}}{1.5}, \, \frac{h}{1.5}, \, \frac{s_{2,max}}{3} \right \} \) is used instead

- c2 – smaller distance to the concrete edge perpendicular to the distance c1

- dnom – nominal anchor diameter

- Ac,V0 = 4.5 c12 – area of a concrete cone of an individual anchor at the lateral concrete surface not affected by edges

- Ac,V – actual area of the concrete cone of the anchorage at the lateral concrete surface

- \(\psi_{s,V} = 0.7+0.3 \frac{c_2}{1.5 c_1} \le 1.0 \) – factor which takes account of the disturbance of the distribution of stresses in the concrete due to further edges of the concrete member on the shear resistance

- \( \psi_{h,V} = \left ( \frac{1.5 c_1}{h} \right ) ^ {0.5} \ge 1.0 \) – factor which takes account of the fact that the shear resistance does not decrease proportionally to the member thickness as assumed by the ratio Ac,V / Ac,V0

- \( \psi_{ec,V} = \frac{1}{1+2 e_V / (3c_1)} \le 1 \) – factor which takes account of a group effect when different shear loads are acting on the individual anchors of a group

- \( \psi_{\alpha,V} = \sqrt{\frac{1}{(\cos \alpha_V)^2 + (0.5 \sin \alpha_V)^2}} \ge 1 \) – takes account of the angle αV between the load applied, V, and the direction perpendicular to the free edge of the concrete member

- ψre,V = 1.0 – factor takes account of the effect of the type of reinforcement used in cracked concrete

- h – concrete block height

- γMc = γc – partial safety factor (EN 1992-4 – Table 4.1, γinst = 1.0 for shear loading)

- γc – partial safety factor for concrete (editable in Code setup)

Interaction of tension and shear in steel (EN 1993-1-8 – Table 3.4)

The interaction of tension and shear for cast-in anchors is not necessary because it is implicitly included in the anchor shear check.

Explanation at Steel support from the Netherlands:

For checking of normal bolts, Table 3.4 of EN 1993-1-8 includes a formula for the interaction of normal force and shear force. However, this formula only applies to bolts in a normal (steel-steel) connection and not to anchors in a column base plate connection. When checking the shear resistance of the anchor, a tensile force in the bolt equal to the resistance to yielding was already taken into account; see Eq. 6.2 of Cl. 6.2.2 (7) of EN 1993-1-8. The actual tensile stress that occurs in the anchor is therefore not relevant. This calculation method is based on tests carried out at the TU Delft. These calculation rules from the Eurocode are identical to the calculation rules from the TGB series. The explanation of the calculation rule is included in NEN 6772 but not in EN 1993-1-8. For column base plate connections, it is therefore sufficient to only carry out the separate checks for tension and shear.

Interaction of tension and shear in steel (EN 1992-4 – Table 7.3)

The interaction of tension and shear for post-installed fasteners is determined separately for steel and concrete failure modes according to Table 7.3. Interaction in steel is checked according to Equation (7.54). The interaction in steel is checked for each anchor separately.

\[ \left ( \frac{N_{Ed}}{N_{Rd,s}} \right )^2 + \left ( \frac{V_{Ed}}{V_{Rd,s}} \right )^2 \le 1.0 \]

Interaction of tension and shear in concrete

Interaction in concrete is checked according to Equation (7.55).

\[ \left ( \frac{N_{Ed}}{N_{Rd,i}} \right )^{1.5} + \left ( \frac{V_{Ed}}{V_{Rd,i}} \right )^{1.5} \le 1.0 \]

The largest value of \(N_{Ed} / N_{Rd,i} \) and \(V_{Ed} / V_{Rd,i} \) for the different failure modes shall be taken. Note that values of \(N_{Ed}\) and \(N_{Rd,i}\) often belong to a group of anchors.

Anchors with stand-off

An anchor with stand-off is designed as a bar element loaded by shear force, bending moment, and compressive or tensile force. These internal forces are determined by the finite element model. The anchor is fixed on both sides, one side is 0.5×d below the concrete level, and the other side is in the middle of the thickness of the plate. The buckling length is conservatively assumed as twice the length of the bar element. Plastic section modulus is used. The bar element is designed according to EN 1993-1-1. The shear force may decrease the yield strength of the steel according to Cl. 6.2.8 but the minimum length of the anchor to fit the nut under the base plate ensures that the anchor fails in bending before the shear force reaches half the shear resistance. The reduction is therefore not necessary. The interaction of bending moment and compressive or tensile strength is assessed according to Cl. 6.2.1.

Shear resistance (EN 1993-1-1 Cl. 6.2.6):

\[ V_{pl,Rd} = \frac{A_V f_y / \sqrt{3}}{\gamma_{M2}} \]

where:

- AV = 0.844 As – shear area

- As – bolt area reduced by threads

- fy – bolt yield strength

- γM2 – partial safety factor

Tensile resistance (EN 1993-1-8 – Cl. 3.6.1):

\[ F_{t,Rd}=\frac{c k_2 f_{ub} A_s}{\gamma_{M2}} \ge F_t \]

where:

- c – decrease in tensile resistance of bolts with cut thread according to EN 1993-1-8 – Cl. 3.6.1. (3) editable in Code setup

- k2 = 0.9 – factor from Table 3.4 in EN 1993-1-8

- fub – anchor bolt ultimate strength

- As – anchor bolt tensile stress area

- γM2 – safety factor (EN 1993-1-8 – Table 2.1; editable in Code setup)

Compressive resistance (EN 1993-1-1 Cl. 6.3):

\[ F_{c,Rd} = \frac{\chi A_s f_y}{\gamma_{M2}} \]

where:

- \( \chi = \frac{1}{\Phi + \sqrt{\Phi^2 - \bar\lambda^2}} \le 1 \) – buckling reduction factor

- \( \Phi = 0.5 \left [1+ \alpha (\bar\lambda - 0.2) + \bar\lambda^2 \right ] \) – value to determine buckling reduction factor χ

- α = 0.49 – imperfection factor for buckling curve c (belonging to the full circle)

- \( \bar\lambda = \sqrt{\frac{A_s f_y}{N_{cr}}} \) – relative slenderness

- \( N_{cr} = \frac{\pi^2 E I}{L_{cr}^2} \) – Euler's critical force

- \( I = \frac{\pi d_s^4}{64} \) – moment of inertia of the bolt

- Lcr = 2 l – buckling length; it is assumed on the safe side that the bolt is fixed in the concrete and able to rotate at the base plate freely

- l – length of the bolt element equal to half the base plate thickness + gap + half the bolt diameter; it is assumed on the safe side that the washer and a nut are not clamped to the concrete surface (ETAG 001 – Annex C – Cl. 4.2.2.4)

Bending resistance (EN 1993-1-1 Cl. 6.2.5):

\[ M_{pl,Rd} = \frac{W_{pl} f_y}{\gamma_{M2}} \]

- \( W_{pl}= \frac{d_s^3}{6} \) – section modulus of the bolt

- fy – bolt yield strength

- γM2 – partial safety factor

Anchor steel utilization (EN 1993-1-1 Cl. 6.2.1)

\[ \frac{N_{Ed}}{N_{Rd}} + \frac{M_{Ed}}{M_{Rd}} \le 1 \]

where:

- NEd – tensile (positive) or compressive (negative sign) design force

- NRd – tensile (positive, Ft,Rd) or compressive (negative sign, Fc,Rd) design resistance

- MEd – design bending moment

- MRd = Mpl,Rd – design bending resistance

Detailing

A detailing check of anchors is performed if the option is selected in the Code setup. Only minimum spacing between anchors (measured centreline to centreline) is checked. The minimum spacing differs for each anchor type and is given in the European Technical Product Specification. Users can modify limit spacing value in the Code setup as a multiple of anchor bolt diameter.

Edge distances to steel plates follow the rules for bolts, i.e. e = 1.2 is recommended in Table 3.3 in EN 1993-1-8. User can modify this value in Code setup.

Verifica in accordo al codice dei blocchi in calcestruzzo (EN)

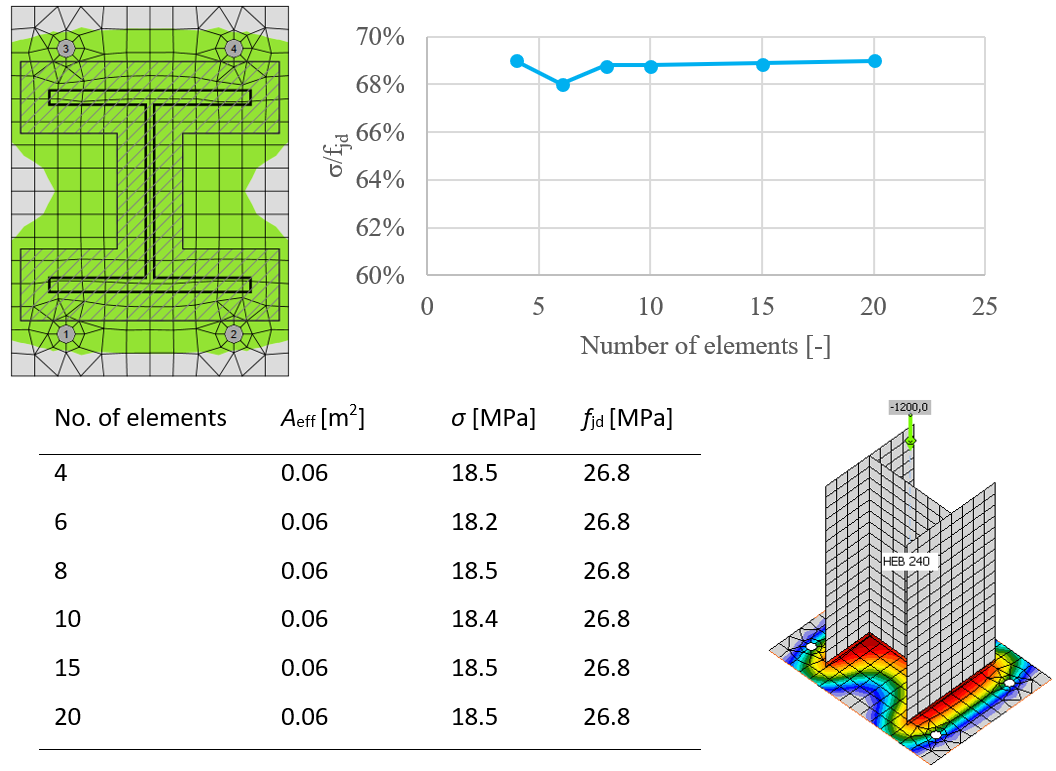

Il calcestruzzo al di sotto della piastra di base è simulato dal sottosuolo di Winkler con rigidezza uniforme, che fornisce le tensioni di contatto. Per la verifica a compressione si utilizza la tensione media in corrispondenza dell'area efficace determinata dalla norma EN 1993-1-8.

La resistenza del calcestruzzo in compressione 3D è determinata in base alla norma EN 1993-1-8, calcolando la resistenza di progetto del calcestruzzo nel giunto, fjd, sotto l'area efficace, Aeff, della piastra di base. La resistenza portante di progetto del giunto, fjd, è valutata in base alla Cl. 6.2.5 della EN 1993-1-8 e alla Cl. 6.7 della EN 1992-1-1. La qualità e lo spessore della malta sono introdotti dal coefficiente del giunto, βjd. Per una qualità del giunto di malta pari o superiore a quella del blocco di calcestruzzo, si prevede un valore di βjd = 1,0, mentre la norma EN 1993-1-8 raccomanda un valore di βjd = 0,67. L'area effettiva, Aeff,cm sotto la piastra di base è stimata essere della forma della sezione trasversale della colonna aumentata della larghezza di appoggio aggiuntiva, c.

\[ c = t \sqrt{\frac{f_y}{3 f_{jd} \gamma_{M0}}} \]

dove t è lo spessore della piastra di base, fy è la resistenza allo snervamento della piastra di base e γM0 è il fattore di sicurezza parziale per l'acciaio.

L'area effettiva viene calcolata per iterazione fino a quando la differenza tra le larghezze di appoggio aggiuntive dell'iterazione corrente e di quella precedente |ci -ci-1 | è inferiore a 1 mm. Per la prima iterazione, l'area della piastra di base viene assunta come area portante, Ac0.

L'area in cui il calcestruzzo è in compressione viene ricavata dai risultati di FEA. Quest'area in compressione, Aeff,FEM, consente di determinare la posizione dell'asse neutro. L'utente può modificare quest'area modificando il parametro "Area effettiva - influenza della dimensione della mesh" in Impostazione del progetto. Il valore predefinito è 0,1 per il quale sono stati effettuati gli studi di verifica. Non è consigliabile diminuire questo valore. L'aumento di questo valore rende più sicura la valutazione della resistenza del calcestruzzo. Il valore nella finestra Impostazione del progetto determina il confine dell'area, Aeff,FEM, ad esempio il valore di 0,1 prende in considerazione solo le aree in cui la sollecitazione nel calcestruzzo è superiore a 0,1 volte la sollecitazione massima nel calcestruzzo, σc,max. L'intersezione tra l'area in compressione, Aeff,FEM, e l'area efficace, Aeff,cm, consente di valutare la resistenza per la base della colonna generalmente caricata di qualsiasi forma di colonna con qualsiasi irrigidimento ed è denominata Aeff. La sollecitazione media σ sull'area efficace, Aeff, è determinata come la forza di compressione divisa per l'area efficace. La verifica della componente è in tensioni σ ≤ fjd.

Resistenza del calcestruzzo a compressione concentrata:

\[ f_{jd}= \beta_j k_j \frac{f_{ck}}{\gamma_c} \]

Fattore di concentrazione che tiene conto dell'aumento della resistenza a compressione del calcestruzzo dovuto alla sollecitazione triassiale:

\[ k_j=\sqrt{\frac{A_{c1}}{A_{eff}}} \le 3.0 \]

dove Ac1 è l'area di supporto determinata secondo la EN 1992-1-1 - Cl. 6.7. L'area deve essere concentrica e geometricamente simile all'area portante Aeff.

Tensione media sotto la piastra di base:

\[ \sigma = \frac{N}{A_{eff}} \]

Utilizzo in compressione [%]:

\[ Ut = \frac{\sigma}{f_{jd}} \]

dove:

- fck - resistenza caratteristica a compressione del calcestruzzo

- βj = 0,67 - fattore di qualità della boiacca modificabile nella configurazione del codice

- γc - fattore di sicurezza per il calcestruzzo

- Aeff - area effettiva sulla quale si distribuisce la forza normale N della colonna

L'area efficace, Aeff,cm, calcolata secondo l'EC per la compressione pura, è contrassegnata da una linea tratteggiata. La rappresentazione grafica mostra la modalità di verifica. L'area effettiva calcolata, Aeff,fem, è contrassegnata in verde. L'area effettiva finale, Aeff, per la verifica della sollecitazione di contatto è evidenziata come tratteggiata.

In rare occasioni, soprattutto nel caso di colonne caricate solo a trazione (la compressione del calcestruzzo è causata da forze di trazione) o a trazione e momento flettente, l'intersezione delle aree Aeff,cm e Aeff,fem è estremamente piccola o nulla. In questi casi, le forze di compressione sono generalmente molto piccole, la verifica non rientra nell'ambito dell'Eurocodice e il calcestruzzo in compressione non viene controllato.

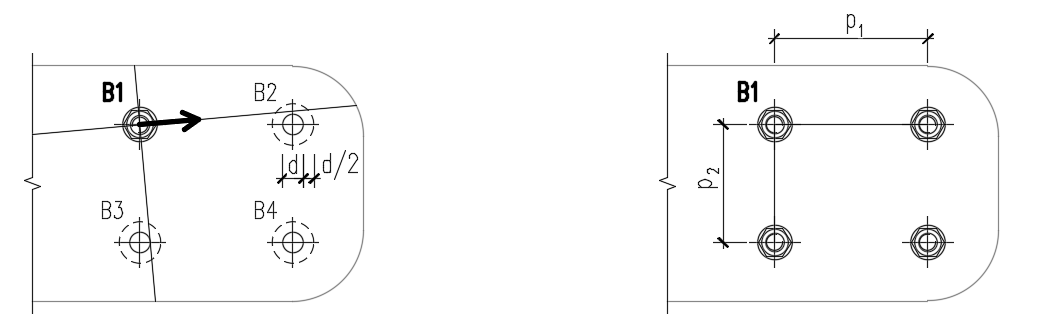

Sensibilità della mesh

Questa procedura di valutazione della resistenza del calcestruzzo in compressione è indipendente dalla maglia della piastra di base, come si può vedere nelle figure seguenti. L'esempio di valutazione del calcestruzzo a compressione secondo l'EC è illustrato. Sono stati analizzati due casi: il carico di compressione pura di 1200 kN e il carico di una combinazione di forza di compressione di 1200 kN e momento flettente di 90 kN.

Influenza del numero di elementi sulla previsione della resistenza del calcestruzzo a compressione in caso di compressione pura

Influenza del numero di elementi sulla previsione della resistenza del calcestruzzo a compressione in caso di compressione e flessione

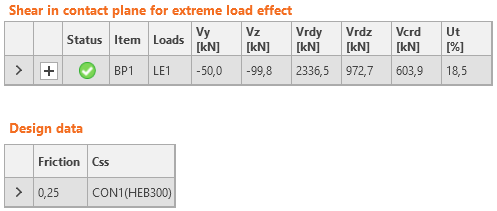

Taglio nel blocco di calcestruzzo

Il taglio nel blocco di calcestruzzo può essere trasferito attraverso una delle tre modalità:

- Attrito

\( Ut = \frac{V}{V_{Rd}} \)

Vrd = N Cf

- Ferro a taglio

\( Ut = \max \left ( \frac{V_y}{V_{Rd,y}}, \, \frac{V_z}{V_{Rd,z}}, \, \frac{V}{V_{c,Rd}} \right ) \) \(V_{Rd,y} = \frac{A_{Vy} f_y}{\sqrt{3} \gamma_{M0}} \)

\( V_{Rd,z} = \frac{A_{Vz} f_y}{\sqrt{3} \gamma_{M0}} \)

\( V_{c,Rd} = A \sigma_{Rd,max} \)

Anche il ferro a taglio e le saldature sono verificati mediante FEM.

- Ancoraggi

La verifica è fornita in conformità alla EN 1992-4.

dove:

- AV,y, AV,z - aree di taglio della sezione trasversale del ferro a taglio in direzione degli assi y e z

- fy - resistenza allo snervamento

- γM0 - fattore di sicurezza

- Vy - componente della forza di taglio nel piano della piastra di base in direzione y

- Vz - componente della forza di taglio nel piano della piastra di base in direzione z

- V - forza di taglio (somma vettoriale di entrambe le componenti della forza di taglio)

- N - forza perpendicolare alla piastra di base

- Cf - coefficiente di attrito tra l'acciaio e il calcestruzzo/la boiacca; modificabile nell'impostazione del Codice

- A = l b - area proiettata del capocorda a taglio, esclusa la parte sopra la superficie del calcestruzzo

- l - lunghezza dell'ansa a taglio, esclusa la parte sopra la superficie del calcestruzzo

- b - larghezza prevista dell'ansa a taglio nella direzione del carico di taglio

- σRd,max = k1 v' fcd - sollecitazione massima che può essere applicata ai bordi del nodo

- k1 = 1 - fattore (EN 1992-1-1 - Equazione (6.60))

- v' = 1 - fck / 250- fattore (EN 1992-1-1 - Equazione (6.57N))

- \( f_{cd} = \alpha_{cc} \frac{f_{ck}} {\gamma_c} \) - resistenza alla compressione di progetto del calcestruzzo

- αcc - coefficiente per gli effetti a lungo termine sulla resistenza a compressione del calcestruzzo

- fck - resistenza caratteristica a compressione del calcestruzzo

- γc - fattore di sicurezza per il calcestruzzo

Progettazione in capacità (EN)

La progettazione incapacità fa parte della verifica sismica e garantisce che il giunto abbia una capacità di deformazione sufficiente.

L'obiettivo della progettazione in capacità è quello di confermare che un edificio abbia un comportamento duttile controllato per evitare il collasso in caso di terremoto di livello progettuale. Si prevede che la cerniera plastica appaia nell'elemento dissipativo e tutti gli elementi non dissipativi del giunto devono essere in grado di trasferire in modo sicuro le forze dovute allo snervamento dell'elemento dissipativo. L'elemento dissipativo è solitamente una trave in un telaio resistente al momento, ma può anche essere, ad esempio, una piastra di estremità. Il fattore di sicurezza non viene utilizzato per gli elementi dissipativi. All'elemento dissipativo vengono assegnati due fattori:

- γov - fattore di sovraresistenza - EN 1998-1, Cl. 6.2; il valore raccomandato è γov = 1,25; modificabile nei materiali.

- γsh - fattore di incrudimento; i valori consigliati sono γsh = 1,2 per travi in telai resistenti al momento, γsh = 1,0 altrimenti; modificabile in esercizio

Il diagramma dei materiali viene modificato secondo la figura seguente:

L'aumento della resistenza dell'elemento dissipativo consente l'inserimento di carichi che causano la comparsa della cerniera plastica nell'elemento dissipativo. Nel caso di un telaio resistente al momento e di una trave come elemento dissipativo, la trave deve essere caricata da My,Ed = γovγshfyWpl,y e dalla corrispondente forza di taglio Vz,Ed = -2My,Ed / Lh, dove:

- fy - resistenza caratteristica allo snervamento

- Wpl,y - modulo di sezione plastica

- Lh - distanza tra le cerniere plastiche della trave

Nel caso di un giunto asimmetrico, la trave deve essere caricata sia dai momenti flettenti positiviche da quelli negativi e dalle corrispondenti forze di taglio.

Le piastre degli elementi dissipativi sono escluse dalla verifica.

Buckling analysis (EN)

The load resistance of slender components may be determined by a combination of linear buckling analysis and materially nonlinear analysis.

There are five categories of finite element structural analysis with the following assumptions:

- Linear material, geometrically linear

- Nonlinear material, geometrically linear

- Linear material, linear loss of stability – buckling

- Linear material, geometrically nonlinear using imperfections

- Nonlinear material, geometrically nonlinear using imperfections

A design procedure that combines approaches 2 and 3 – material nonlinearity and stability analysis – is mentioned in Chapter 8 of EN 1993-1-6. The verification of buckling resistance based on the obtained FEM results is described in Annex B of EN 1993-1-5. This procedure is used for a wide range of structures except for very slender shells, where geometrically nonlinear analysis with initial imperfections is more suitable (4 and 5).

The procedure uses load amplifiers α, which are obtained as the results of FEM analysis and allow to predict of the post-buckling resistance of the joints.

The load coefficient, αult,k, is determined by reaching the plastic capacity without considering the geometrical nonlinearity. The check of plastic capacity and the general automatic determination of αult,k is implemented into the developed software.

The critical buckling factor, αcr, is determined, which is obtained using FEM analysis of linear stability. It is determined automatically in the software using the same FEM model as for the calculation of αult,k. It should be noted that the critical point in terms of plastic resistance is not necessarily assessed in the first critical buckling mode. More buckling modes need to be assessed in a complex joint because they are related to different parts of the joint.

The non-dimensional plate slenderness, \( \bar \lambda_p \), of the examined buckling mode is determined:

\[ \bar \lambda_p = \sqrt{\frac{\alpha_{ult,k}}{\alpha_{cr}}} \]

The reduction buckling factor ρ is determined according to Annex B of EN 1993-1-5. The reduction factor depends on the plate slenderness. The used buckling curve shows the influence of the reduction factor on the plate slenderness. The provided buckling factor applicable to non-uniform members is based on the buckling curves of a beam. The verification is based on the von Mises yield criterion and the reduced stress method. Buckling resistance is assessed as

\[ \frac{\alpha_{ult,k} \rho}{\gamma_{M2}} \ge 1 \]

Buckling reduction factor ρ according to EN 1993-1-5 Annex B

Although the process seems trivial, it is general, robust, and easily automated. The advantage of the procedure is the advanced FEM analysis of the whole joint, which can be applied to general geometry. Moreover, it is included in the valid Eurocode standards. The advanced numerical analysis gives a quick overview of the global behavior of the structure and its critical parts and allows fast stiffening to prevent instabilities.

The limit slenderness, λp, is provided in Annex B of EN 1993-1-5 and sets all cases which must be assessed according to the previous procedure. The resistance is limited by buckling for plate slenderness higher than 0.7. With the decreasing slenderness, the resistance is governed by plastic strain. The limit critical buckling factor for plate slenderness equals to 0.7, and buckling resistance equal to the plastic resistance may be obtained as follows

\[ \alpha_{cr} = \frac{\alpha_{ult,k}}{\bar \lambda_p^2} = \frac{1}{0.7^2} = 2.04 \]

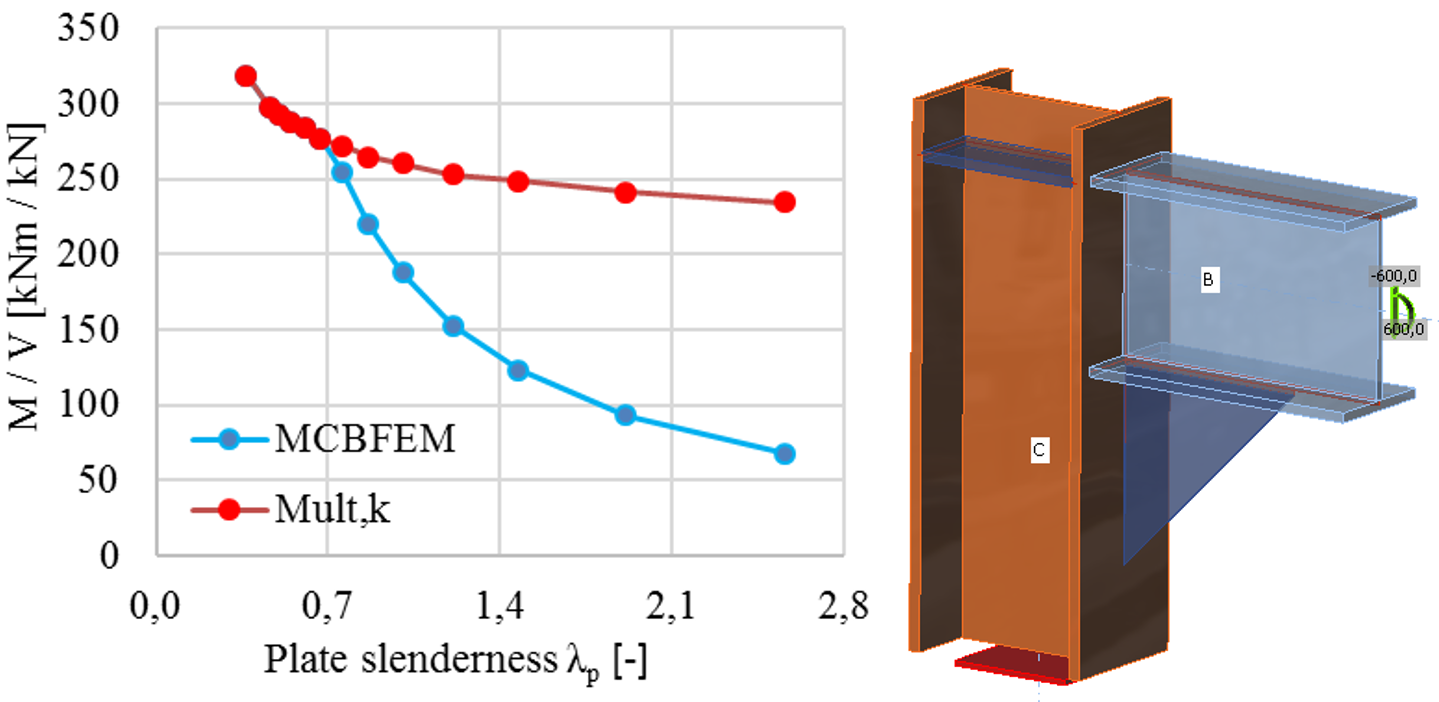

The influence of the plate slenderness on the plastic resistance, Mult,k, and buckling resistance, MCBFEM, is shown in the figure below. The diagram shows the results of a numerical study of a triangular stiffener in a portal frame joint.

The influence of plate slenderness on the resistance of portal frame joint with slender stiffener

Joint classification (EN)

Joints are classified according to joint stiffness to:

- Rigid – joints with insignificant change of original angles between members,

- Semirigid – joints which are assumed to have the capacity to furnish a dependable and known degree of flexural restraint,

- Pinned – joints which do not develop bending moments.

Joints are classified according to the EN 1993-1-8 – Cl. 5.2.2.

- Rigid – \( \frac{S_{j,ini} L_b}{E I_b} \ge k_b \)

- Semirigid – \( 0.5 < \frac{S_{j,ini} L_b}{E I_b} < k_b \)

- Pinned – \( \frac{S_{j,ini} L_b}{E I_b} \le 0.5 \)

where:

- Sj,ini – initial stiffness of the joint; the joint stiffness is assumed linear up to the 2/3 of Mj,Rd

- Lb – theoretical length of the analyzed member; set in member properties

- E – Young's modulus of elasticity

- Ib – moment of inertia of the analyzed member

- kb = 8 for frames where the bracing system reduces the horizontal displacement by at least 80 %; kb = 25 for other frames, provided that in every storey Kb/Kc ≥ 0.1. The value of kb = 25 is used unless the user sets "braced system" in Code setup.

- Mj,Rd – joint design moment resistance

- Kb = Ib / Lb

- Kc = Ic / Lc

Tying orizzontale

Le connessioni devono essere progettate per trasformare la forza di trazione generata dagli effetti del secondo ordine: la colonna viene rimossa e il solaio funge da membrana.

Vincoli

Viene analizzato un solo elemento e tutti gli altri sono fissati alle estremità. All'elemento analizzato deve essere applicata solo la forza normale, quindi il suo tipo di modello è impostato su N-Vy-Vz (i momenti flettenti e la torsione sono limitati).

Carico

La forza normale che agisce sull'elemento analizzato deve essere determinata secondo la norma EN 1993-1-7, Cl. A.5.1:

Per gli incatenamenti interni:

\[T_i=0,8(g_k+psi q_k) s L \ge 75 \textrm{ kN} \]

Per gli incatenamenti perimetrali:

\[T_p=0,4(g_k+\psi q_k) s L \ge 75 \textrm{ kN} \]

dove:

- \(g_k\) - carico caratteristico permanente

- \(q_k\) - carico caratteristico imposto

- \(s\) - spaziatura degli incatenamenti

- \(L\) - campata degli incatenamenti

- \(\psi\) - fattore rilevante nell'espressione per una combinazione di effetti di azione per la situazione di progetto accidentale (cioè \(\psi_1\) o \(\psi_2\) in conformità all'espressione (6.11b) della norma EN 1990).

Modello del materiale e verifiche

Secondo la norma SCI P358: Giunti nelle costruzioni in acciaio: Giunti semplici secondo l'Eurocodice 3 - Appendice A, è stato introdotto il coefficiente di sicurezza parziale per gli incatenamenti orizzontali, \(\gamma_{Mu}\) con valore predefinito 1,1 modificabile nelle Impostazioni del progetto. Questo coefficiente di sicurezza viene utilizzato per piastre, bulloni e saldature nell'analisi degli incatenamenti orizzontali.

Sono previsti carichi e deformazioni estremi e la progettazione delle piastre si basa sulla resistenza ultima delle piastre, \(f_u\). Per questo motivo, il modello del materiale per l'analisi agli elementi finiti si comporta elasticamente fino a \(f_u / \gamma_{Mu}\). La pendenza del ramo plastico è il modulo di elasticità di Young \(E/1000\). La verifica viene eseguita per il limite di deformazione plastica del 5%.

Le resistenze di bulloni e saldature sono calcolate con \(\gamma_{Mu}\) invece che con \(\gamma_{M2}\). Utilizzando i valori predefiniti dei fattori di sicurezza parziali, le resistenze al carico sono superiori di circa il 14% rispetto allo stato limite ultimo.

Si ipotizza che i bulloni precaricati scorrano e vengono verificati come normali bulloni ben serrati.

Riferimenti

EN 1993-1-7: Eurocodice 1 - Azioni sulle strutture - Parte 1-7: Azioni generali - Azioni accidentali, CEN, 2006.

SCI P358: Giunti nelle costruzioni in acciaio: Giunti semplici secondo l'Eurocodice 3