Weld Optimization: A Balancing Act

Optimizing welds involves more than just achieving strength, it’s about finding the right balance between efficiency, safety, and material usage. Connection designers often struggle with deciding how much weld is “just enough,” while engineers revising designs need clarity on how much more load their connections can handle without risking failure. Misjudgments in either direction can lead to unnecessary costs, extended fabrication times, or, in worst cases, safety concerns.

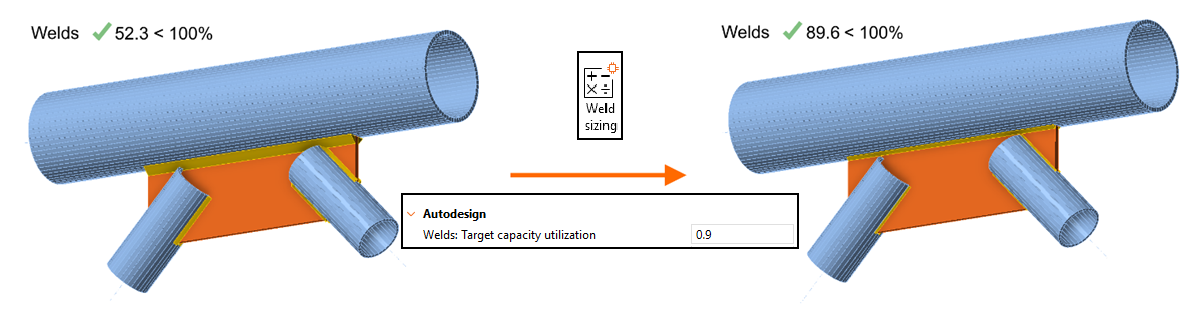

Precision with Automatic Weld Sizing

For connection designers, the Automatic Weld Sizing to Capacity Estimation feature provides a powerful advantage. By analyzing the entire connection model, this tool optimizes each weld’s size, ensuring it’s precisely calibrated for the applied loads. Instead of relying on broad assumptions or conservative estimates, designers can make informed decisions about weld dimensions, saving material and fabrication time across the entire structure.

Imagine a large steel frame project where dozens of fillet welds connect beams and columns. A small optimization of just 1/16 of an inch per weld might seem negligible, but when multiplied across hundreds of connections, the savings in material and labor become significant.

This feature helps designers achieve leaner, more efficient designs while maintaining the necessary strength and compliance with structural codes.

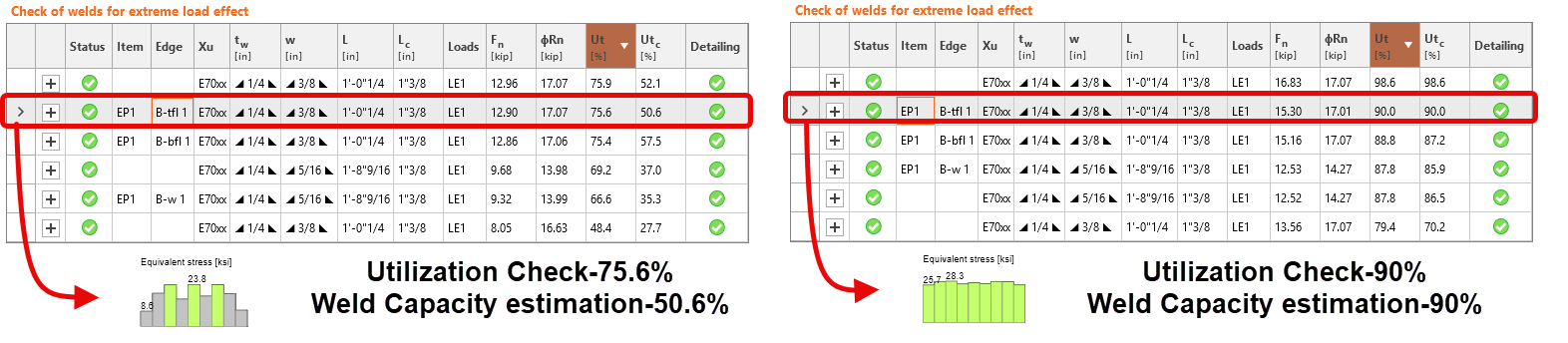

Insight with Weld Capacity Estimation

For engineers revising existing designs or performing quality checks, the Weld Capacity Estimation percentage feature offers unparalleled clarity. By providing a percentage-based capacity estimation of the entire weld length, it enables users to see exactly how much load each weld can still handle. This tool is invaluable for ensuring that welds are neither underutilized nor dangerously overstressed.

Consider a scenario where a project experiences unexpected load changes late in the design phase. Instead of overhauling the connection details or adding excessive weld material, engineers can use this tool to understand whether existing welds can safely accommodate the new demands. This level of precision allows for smarter, faster revisions without compromising safety or project schedules.

Tackling Real-World Challenges

Structural engineers and pre-fabricators are no strangers to the challenges of weld optimization. Tight project deadlines, fluctuating budgets, and evolving design requirements make it difficult to ensure efficient yet safe welds. Without the right tools, engineers often resort to conservative over-designs, leading to higher costs and wasted materials.

These advanced weld optimization tools address these challenges directly, offering both connection designers and revising engineers a streamlined way to make data-driven decisions. Whether it’s achieving leaner designs or gaining confidence in load-carrying capacity, these features provide engineers with the clarity and precision they need to deliver safe, cost-effective connections on time.

The Bottom Line

Weld optimization isn’t just about cutting costs; it’s about smarter engineering. The ability to fine-tune weld sizes and evaluate capacity with confidence means projects can move forward efficiently, without the delays or extra expenses that come from uncertainty.

Take your connection design to the next level with tools that make complex weld analysis seamless. Download IDEA StatiCa today and see how it transforms your workflow with precision and clarity.