Life Science Research building in Philadelphia

About the project

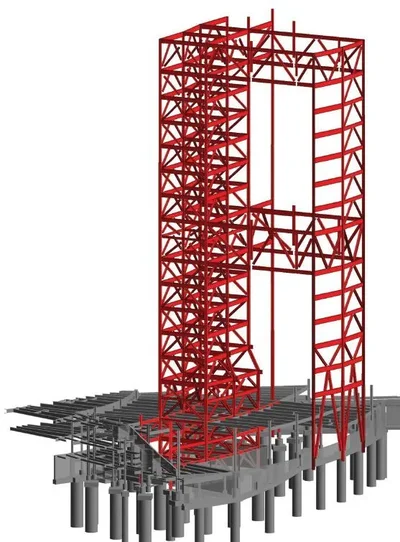

A 5100-ton steel structure built on top of an existing two-story podium originally designed to support vertical expansion. A change of use for the new structure required a highly specialized engineering approach to ensure the existing structure could accommodate the revised function.

The teardrop geometry introduced additional complexities in load distribution, lateral stability, and connection detailing—necessitating advanced analysis tools to optimize material use and guarantee seamless integration with the new design vision.

Engineering challenges

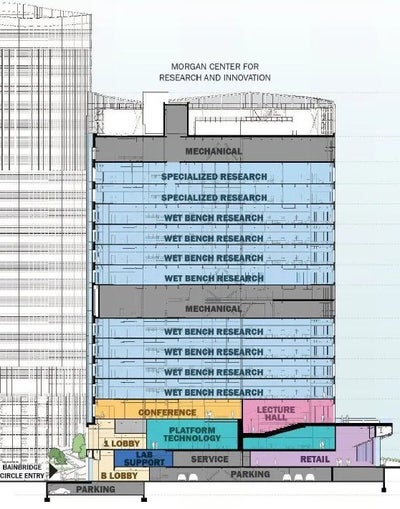

A key requirement was incorporating laboratories, each with a strict 11-ft square dimension. To achieve this, engineers from CannonDesign employed a parametric design strategy, developing an algorithm capable of evaluating hundreds of potential building geometries. This approach allowed the team to determine an optimal configuration that fits within the constraints of the existing podium while efficiently transferring loads from the upper levels and remaining cost-effective. For example, the algorithm was refined to maintain specific critical column locations while simultaneously increasing the number of repeating 33-ft structural bays that could be created.

The position of the braced frame core within the podium was tied to the location of existing beams, columns, and foundations. Nonetheless, it was necessary to realign the column grid on the upper floors. Therefore transfer trusses were integrated into the structure.

More information about the project can be read in the AISC Modern Steel Magazine article: Podium Possibilities by John Roach, PE, SE.

Steel connection design

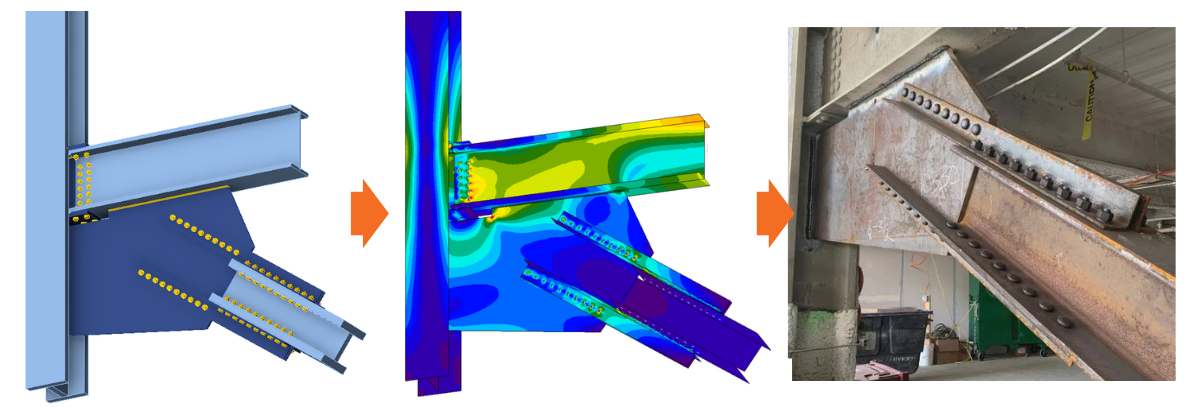

One of the tricky aspects of the project was addressing complex connections caused by the building’s curved geometry. The braced bays followed the teardrop-shaped exterior, meaning none of the brace members could be resolved using standard connection details.

The design team developed compact bracing connections with the following characteristics:

- 2-inch-thick gusset plates welded to the column and bolted to wide flange braces

- Columns and gusset plates shop welded to 6-inch-thick base plates (for shear and uplift forces)

- Cover plates added to wide-flange members to comply with slenderness limits and resist wind forces to optimize the cross-section selection

- Long notches on the gussets to maintain the existing flange plate connections

Due to the new and existing details and new load conditions, structural engineers found it impractical to use the Uniform Force Method in gusset plate connections (AISC traditional calculations).

The solution was to use IDEA StatiCa to design and validate the project's beam-column brace connections. Using CBFEM helped accurately capture stress distribution in the existing connections, optimizing materials, and avoiding the use of extra doubler plates or stiffeners.

IDEA StatiCa has been validated and verified for brace connection at beam-column connection in a braced frame with the AISC procedure. In this verification study, ten components are examined: brace, beam flange and web, column flange and web, connecting angles, gusset plate, splice plates between brace and gusset plate, connecting angles to the column, connecting angles to beam, bolts, and welds. All components are designed according to AISC 360-16 specifications. The connection presented is taken from AISC Design Guide 29.

Conclusion

By transforming an existing podium originally intended for a hotel into the foundation for a 17-story teardrop-shaped research tower, the project pushed the boundaries of structural adaptability and optimization. Through the use of parametric design strategies, advanced load transfer solutions, and precision-engineered steel connections, the team overcame the challenges posed by the existing framework while meeting the strict vibration criteria required for sensitive laboratory environments.

Try IDEA StatiCa for free

Rocky Mountain Metropolitan Airport drive-through canopy