How are welds modeled in IDEA StatiCa

The weld resistance is reduced in connections to unstiffened flanges or in long joints due to concentrated stress. The plastic strain in a weld is limited to 5% as in the plate. The design resistance of the fillet weld is determined using the Directional method given in section 4.5.3.2 EN1993-1-8:2006.

Stress development

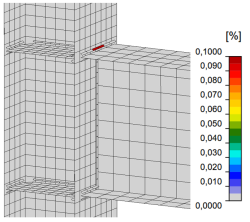

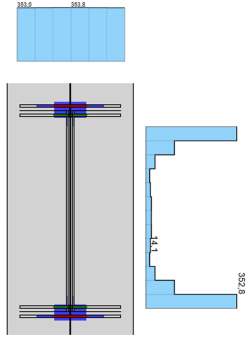

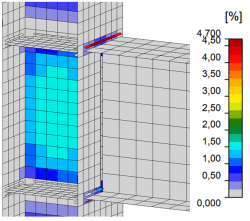

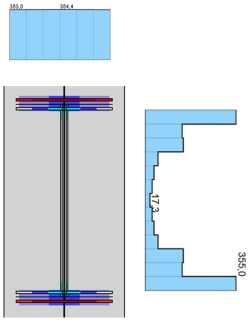

The strain distribution in a welded connection of a beam-to-column joint is shown below. The joint is loaded by bending moment and shear force. The design resistance is governed by yielding in flange weld and is limited by 5% of plastic strain.

1/ Yielding starts in the flange weld

Fd = 0.63 Rd

2/ Yielding starts in the web weld

Fd = 0.95 Rd

3/ Stress in welds at design resistance

Fd = Rd

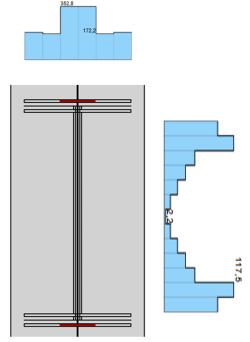

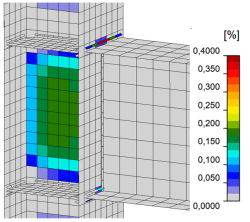

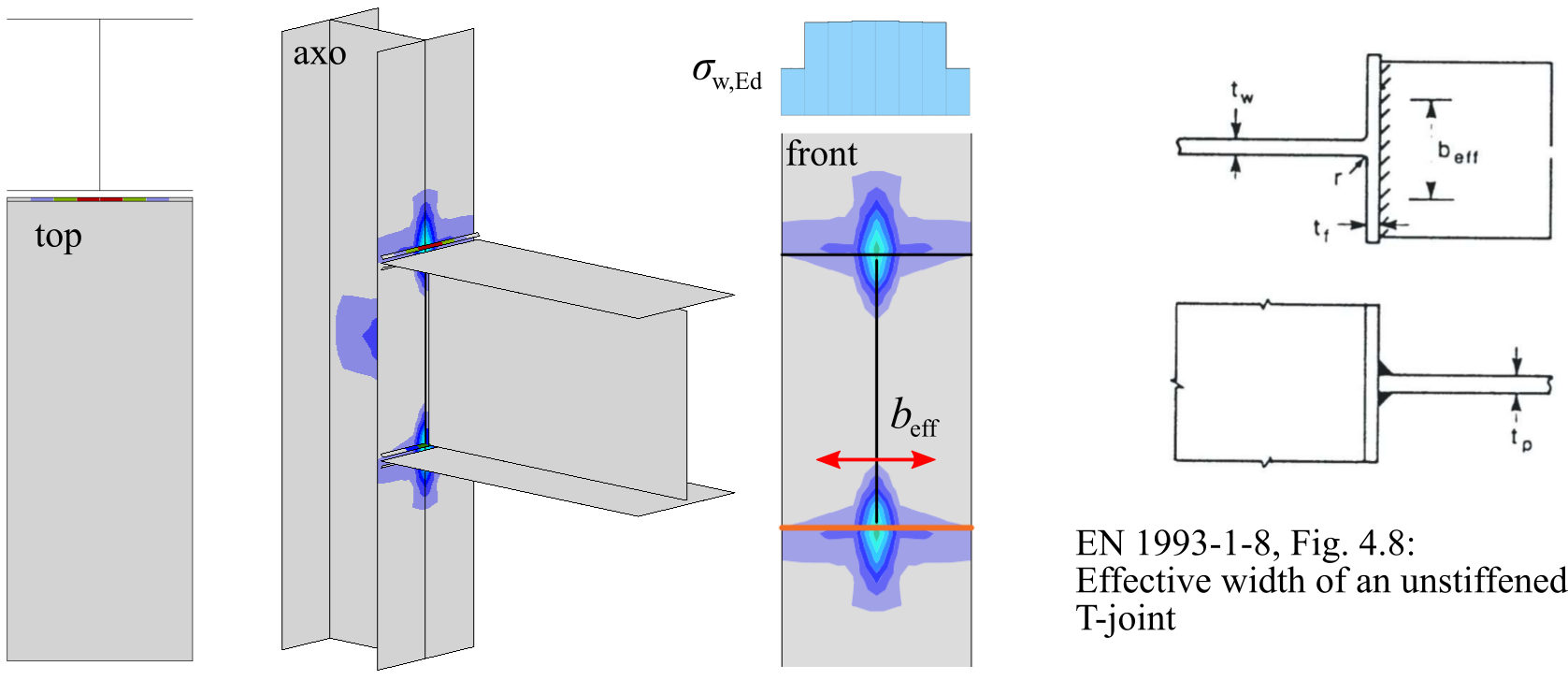

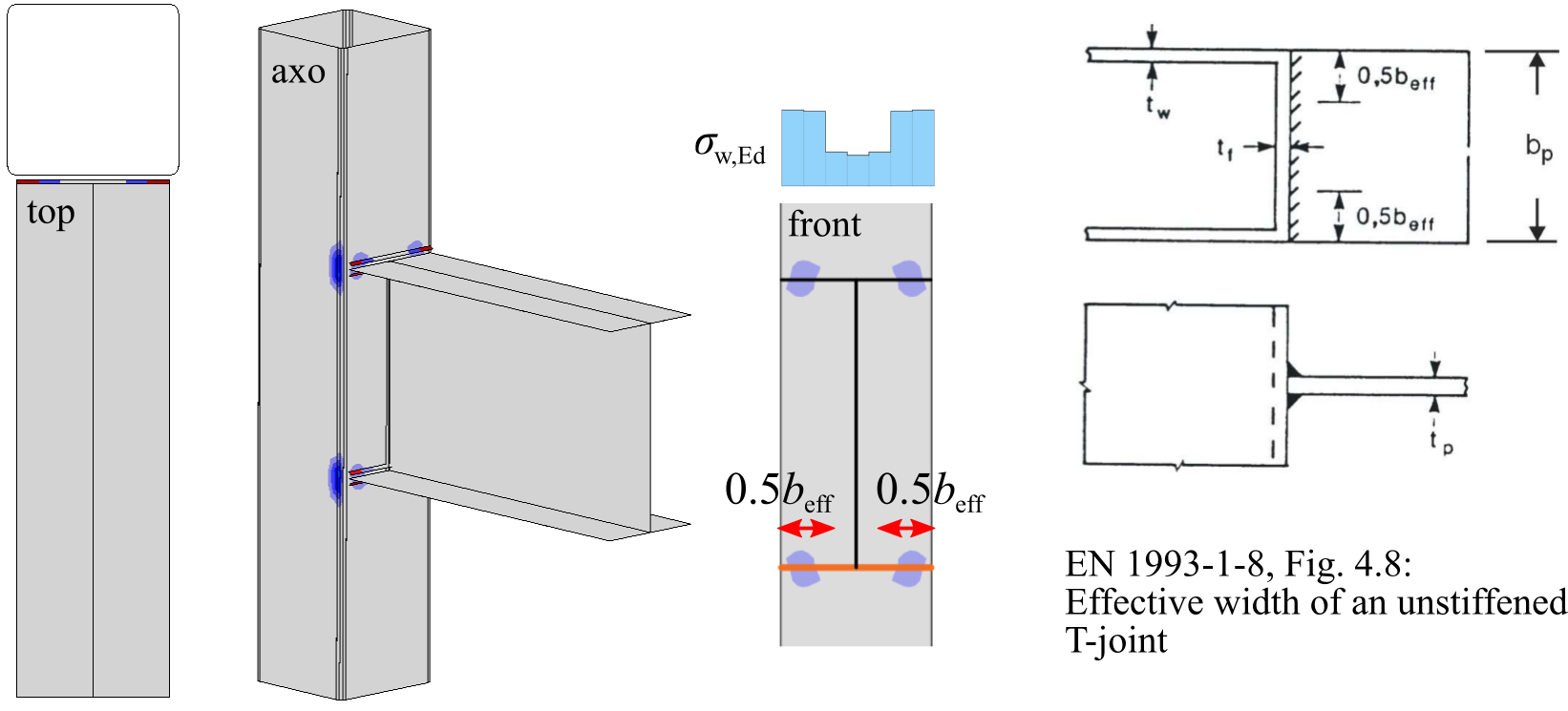

Effective width

The effective width of an unstiffened beam-to-column joint is shown below. The stress is concentrated in an effective width while the weld resistance around the unstiffened parts is reduced. The stress distribution is shown for an open and a box or channel section.

I - section column

RHS - section column

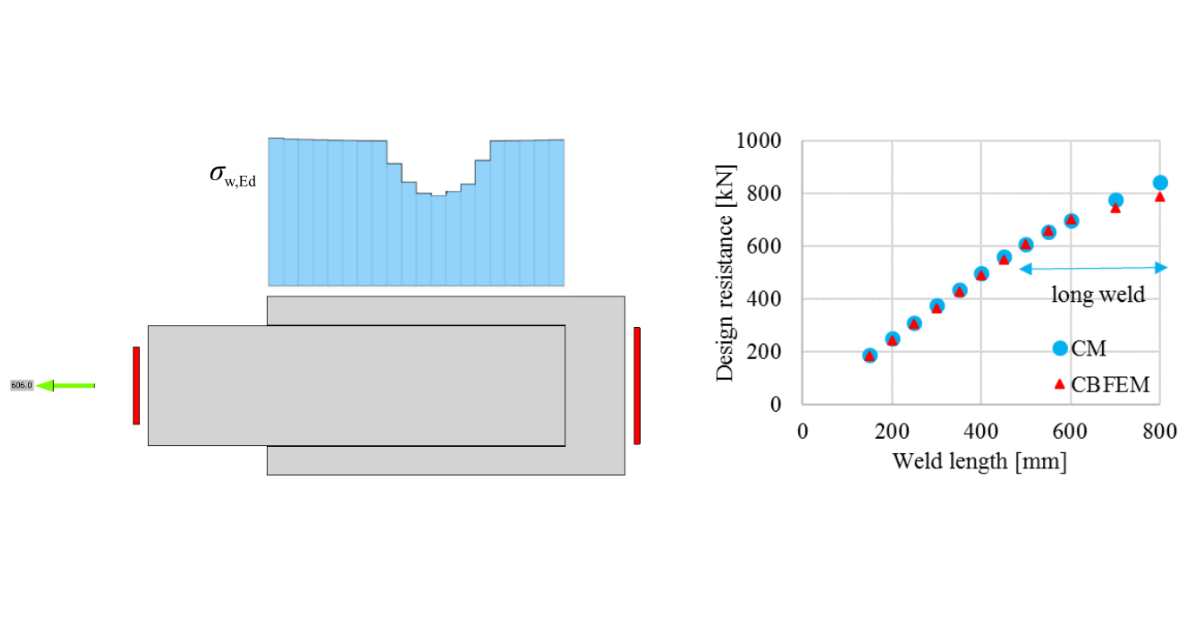

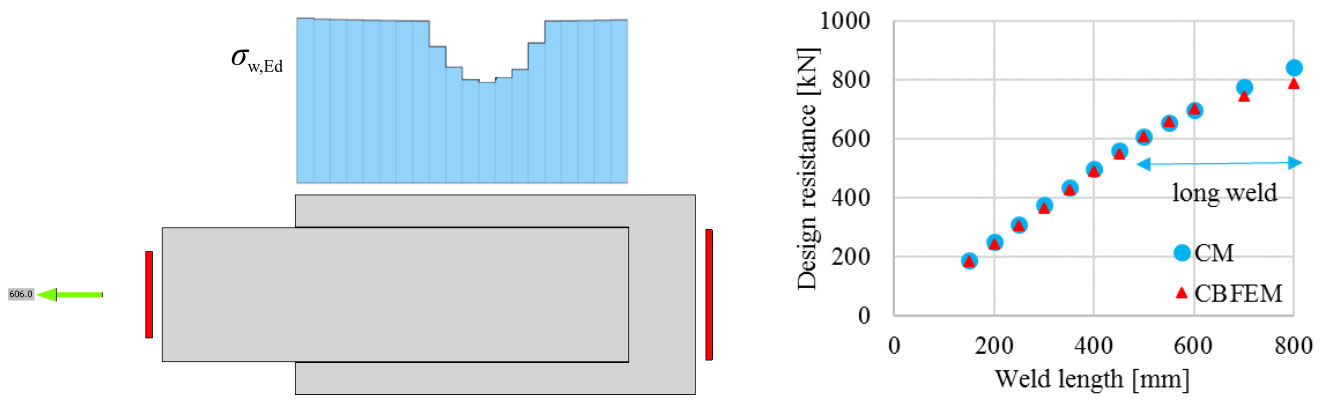

The non-uniform distribution of the stress along its length and the influence of the weld length on the design resistance is shown below. The resistance of a long weld is reduced due to the stress concentration in weld edges.

The weld model respects the properties of the real weld, like geometry, stiffness, and ductility. Plastic redistribution is one of the best features that CBFEM can offer.