Updated CBFEM solver

The computational solver is the heart of CBFEM.

We are constantly improving and refining this numerical method. In version 21, we completed several years of development in the area of geometric nonlinearity and large deformations, including initial imperfections (GMNIA). This allowed us to move the Member application from beta to live.

Wherever the member assessments in their 3D FEA program are not enough for our users, Member is now available to them. The elements are completely modeled including the end connections now, which is beneficial for the designer and frees them from the necessity of estimating the end connection effects on the load capacity and the stability loss. Member can deal with the influence of transverse and longitudinal stiffeners, openings, changes in the cross-section height, but also with the influence of connected secondary members. The effect of torsion and warping is not a problem for this method.

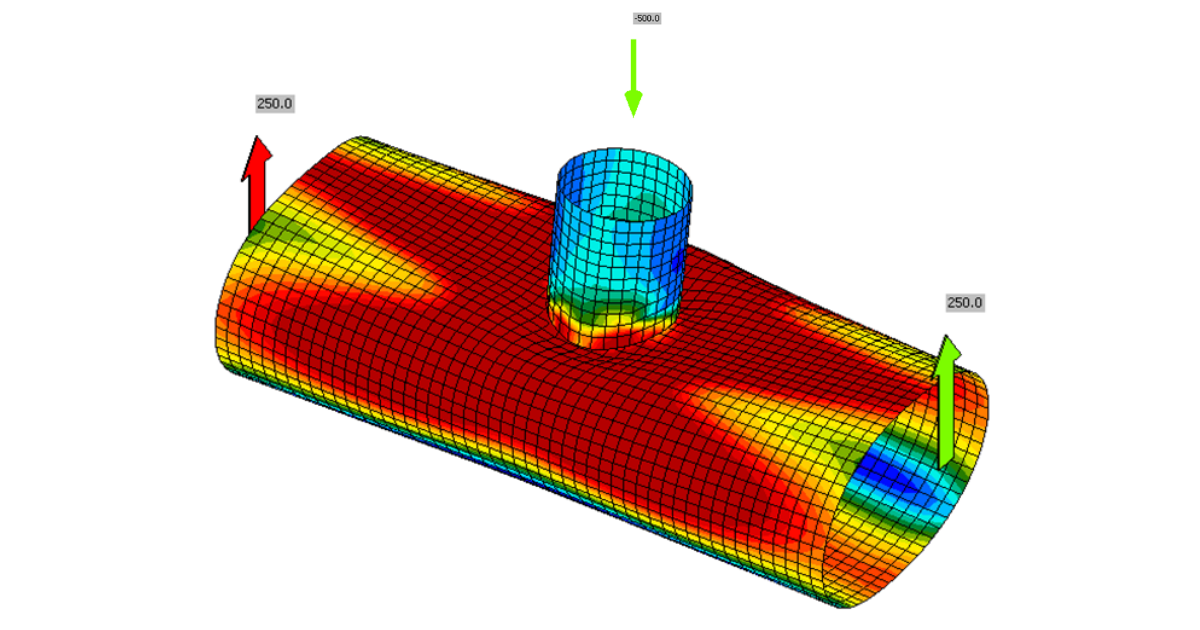

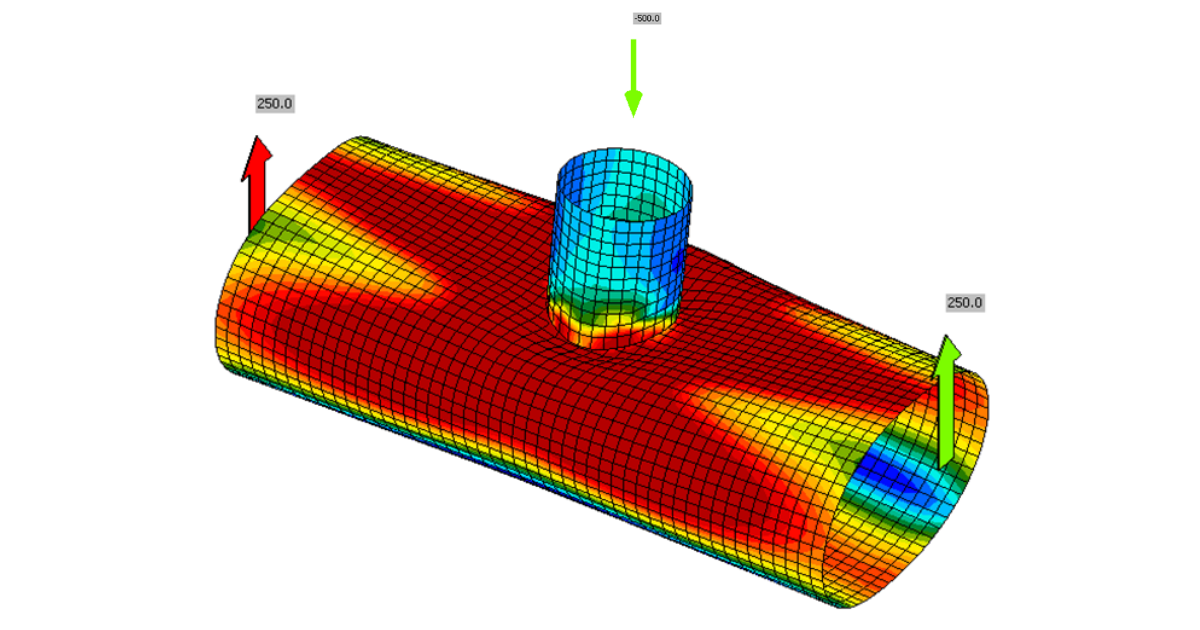

At the same time, the GMNIA method significantly serves to refine the connection models in the Connection app. It is now used in all hollow cross-section connections – circular and rectangular pipes. According to standards, pipe joints are assessed according to empirical formulas, the validity of which is limited to certain geometric conditions. The compliance of these formulas with reality is quite questionable, especially at the edges of the validity intervals. The improved GMNIA method shows very good compliance with standard formulas, especially in the middle parts of the validity intervals. In the marginal ones, it was thoroughly validated against higher mathematical models (ABAQUS) and physical experiments.

Every change in the numerical model necessarily brings a change in the results. This is also reflected in version 21, and in the vast majority of cases, it differs within percentage units.

Moreover, the model improvement also manifests in significant acceleration of the calculation, in the range of up to 30%.

Released in IDEA StatiCa version 21.0.

GMNIA solver

The solver used for the hollow section joints in IDEA StatiCa Connection and also for GMNIA in IDEA StatiCa Member was improved. Now, it contains a nonlinear formulation of not only shell elements (which was already present in previous versions) but also of links and constraints used in components, such as bolts or welds.

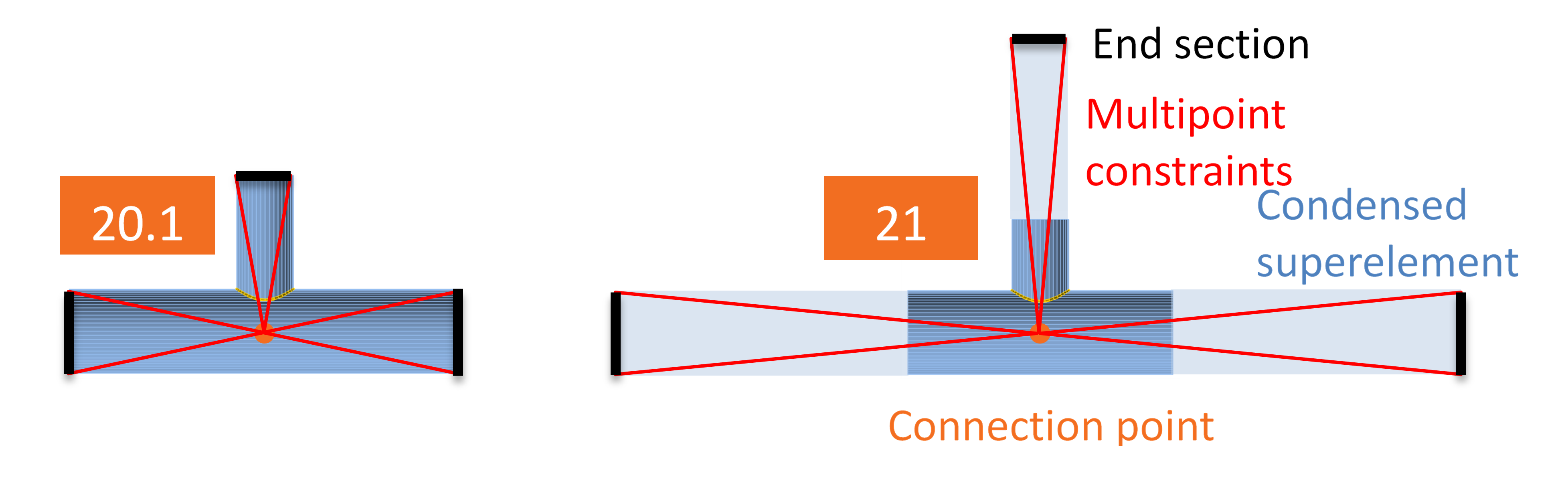

The model of the connection is greatly improved by the insertion of a condensed superelement. This element is added behind the member end and has the same properties as the elastic shell model of the member. It is just one element but it allows any elastic deformation and stress to develop in the member ends. Because of this, the part of the member consisting of shell elements may be shorter and still even improve the model behavior.

A condensed superelement has been added at member ends

This allows shortening the part of the model where shell elements are used and still increases the precision of the model. This results in fewer elements in the model, leading to faster calculation time and visualization of the results.

Cross-section deformations at the end of the shell model

This is the main reason the change was made. The cross-section may deform at the ends of a model consisting of shell elements. Joints of hollow sections require relatively long members – up to 10 times cross-section diameter. By introducing the condensed superelement behind the part of the model consisting of shell elements, the calculation is much faster with the same precision.

Released in IDEA StatiCa version 21.0.

Shell bending resistance reduced for hollow sections (imperfections)

Load resistances of hollow section joints in the codes are determined by the Failure Mode Method, which uses curve-fitting models determined from experiments and advanced numerical models. The real structure contains initial imperfections and residual stresses, which are not captured by shell models in IDEA StatiCa Connection. To achieve closer compliance with the results of codes, the influence of residual stress and initial imperfections was introduced in IDEA StatiCa models by reducing the bending resistance of shells of hollow sections with a high D/(2t) ratio.

These combined changes allowed us to achieve close compliance with the results of the Failure Mode Method contained in design codes.

Released in IDEA StatiCa version 21.0.

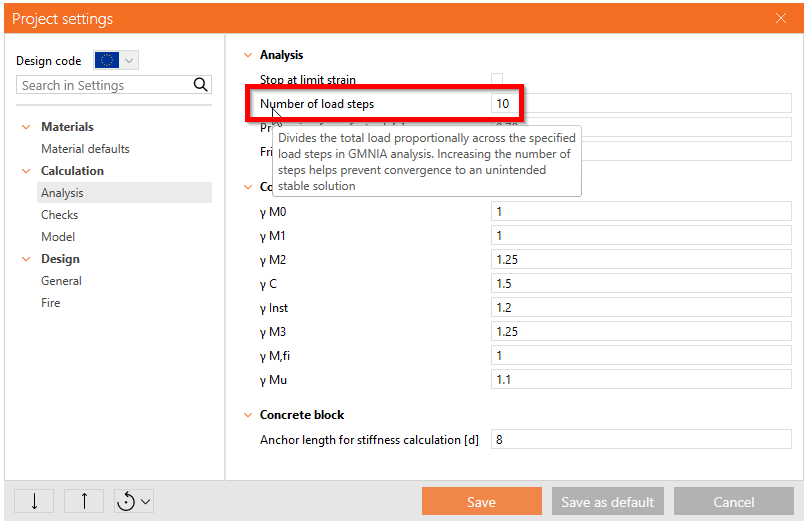

Stepped calculation for GMNIA in Member

The parameter, Number of load steps for GMNIA analysis, has been added to Project settings in Member to improve stability and safety in nonlinear member calculations. The total load is divided into incremental steps (default 10), reducing the risk of the solver converging to an unintended stable branch of the load–deformation curve. This stepped approach ensures smoother load progression, more accurate equilibrium tracking, and safer prediction of ultimate resistance in geometrically and materially nonlinear analyses.

Released in IDEA StatiCa version 25.1.