Knowledge base

Code-check of welds according to Hong Kong Code

Welds are designed according to Cl. 9.2 – Simplified method.

Butt welds

Full penetration butt welds are expected and their resistance is considered equal to that of the parent metal – Cl. 9.2.5.2.1.

Fillet welds

Fillet welds are designed by Simplified method according to Cl. 9.2.5.1.6.

\[ f_w \le p_w \]

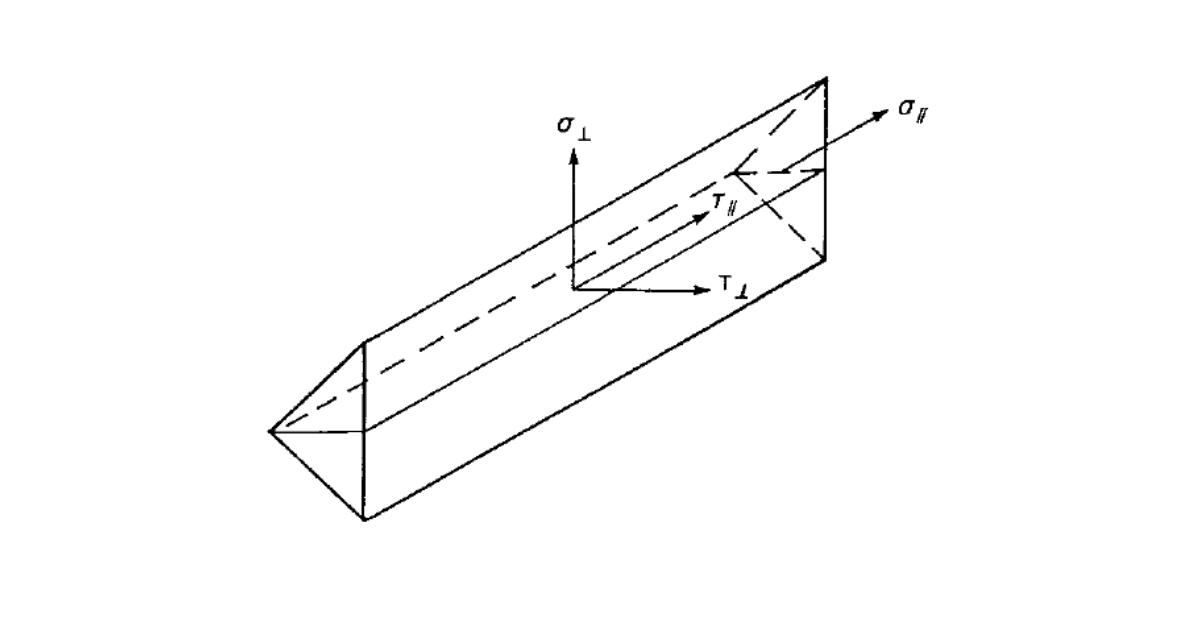

- \(f_w = \sqrt{\sigma_\perp ^2 + \tau_\perp ^2 + \tau_\parallel ^2}\) – vector sum of stresses in weld throat in all directions

- \(p_w\) – design strength of fillet weld determined according to Table 9.2a and 9.2b; for cases not covered by Tables 9.2a and 9.2b:

- \(p_w = \min \{0.5 U_e, 0.55 U_s\}\) – for EN electrode used with EN steel

- \(p_w = 0.38 \min \{U_e, U_s\}\) – for other cases

- \(U_e\) – minimum tensile strength of electrode

- \(U_s\) – minimum tensile strength

The effective length of the fillet weld is reduced by \(2\cdot s\) according to Cl. 9.2.5.1.3, where \(s\) is the fillet weld leg size assumed equal to \(a\cdot \sqrt{2}\).

| Electrode | |||

| Steel grade | 35 | 42 | 50 |

| S 275 | 220 | 220 | 220 |

| S 355 | 220 | 250 | 250 |

| S 460 | 220 | 250 | 280 |

| Steel grade | Electrode | Design strength |

| Q235 | E43 | 160 |

| Q345 | E50 | 200 |

| Q390, Q420 | E55 | 220 |

Tables 9.2a and 9.2b: Design strengths \(p_w\) [MPa]

| Welding electrode | Minimum tensile strength \(U_e\) [MPa] |

| 35 | 440 |

| 42 | 500 |

| 50 | 560 |

| E43 | 421.1 |

| E50 | 526.3 |

| E55 | 578.9 |

Default minimal tensile strength of electrode \(U_e\) [MPa]

The weld diagrams show stress according to the following formula:

\[ \sigma = \sqrt{\sigma_{\perp}^2 + \tau_{\perp}^2 + 3 \tau_{\parallel}^2 } \]